Federal Court of Australia

Globaltech Corporation Pty Ltd v Reflex Instruments Asia Pacific Pty Ltd [2022] FCA 797

Table of Corrections: | |

Second sentence of [292] amended to remove reference in parentheses to patent area. | |

18 July 2022 | Second sentence of [311] amended to remove repeated reference to “armed with the common general knowledge” in parentheses. |

ORDERS

DATE OF ORDER: |

THE COURT ORDERS THAT:

1. The cross-claim be dismissed.

2. The cross-claimant pay the cross-respondent’s costs of and in connection with the cross-claim as agreed or taxed.

3. Within 14 days of today’s date, the parties confer and submit agreed or competing orders finalising the matter including as to costs.

Note: Entry of orders is dealt with in Rule 39.32 of the Federal Court Rules 2011.

JAGOT J:

[1] | |

[3] | |

[25] | |

[35] | |

[35] | |

[36] | |

[40] | |

[41] | |

[41] | |

4.1.3.2 Wired systems for communicating and/or transmitting data downhole | [45] |

[46] | |

[47] | |

[50] | |

[52] | |

[69] | |

[71] | |

[81] | |

[82] | |

[88] | |

[95] | |

[101] | |

[103] | |

[123] | |

[124] | |

[127] | |

[128] | |

[131] | |

[135] | |

[140] | |

[142] | |

[146] | |

[147] | |

[148] | |

[149] | |

[150] | |

[153] | |

4.2.2.12 Wired systems for communicating and/or transmitting data downhole | [158] |

4.2.2.13 Unwired systems for communicating and/or transmitting data downhole | [160] |

[169] | |

[176] | |

[176] | |

[179] | |

[180] | |

[184] | |

[185] | |

[193] | |

[194] | |

[196] | |

[198] | |

[200] | |

[205] | |

[207] | |

[208] | |

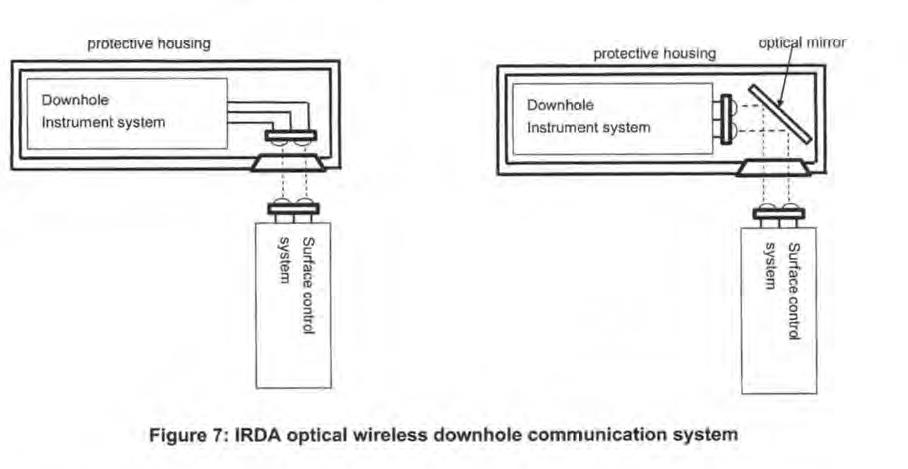

[212] | |

[216] | |

[219] | |

[221] | |

[224] | |

[228] | |

[230] | |

[237] | |

[238] | |

[241] | |

[263] | |

[270] | |

[270] | |

[270] | |

[287] | |

[293] | |

[307] | |

[337] | |

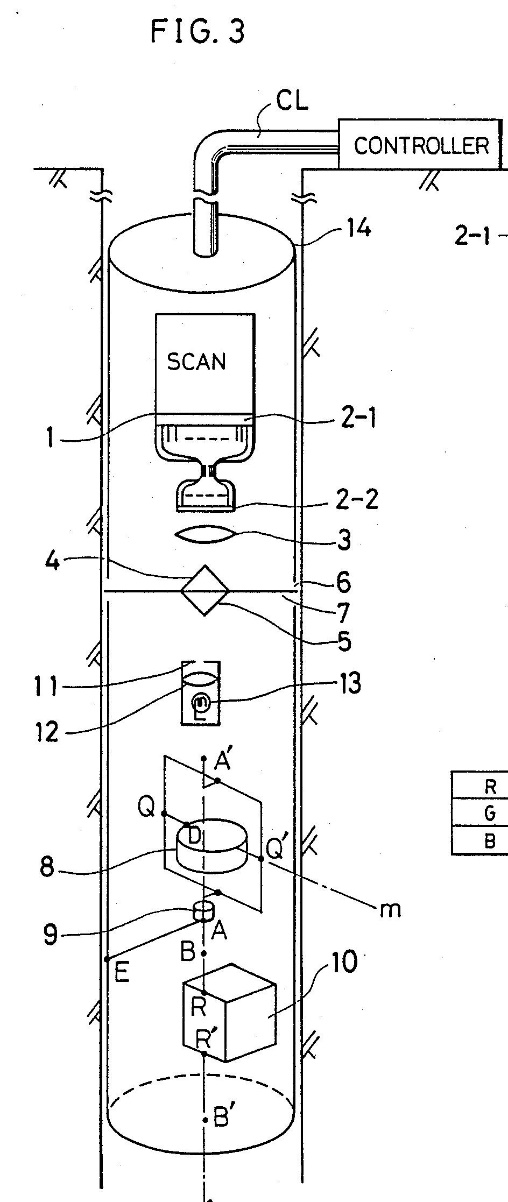

[343] | |

[356] | |

[368] | |

[374] | |

[391] | |

[404] | |

[411] | |

[415] | |

[415] | |

[420] | |

[424] | |

[427] | |

[431] | |

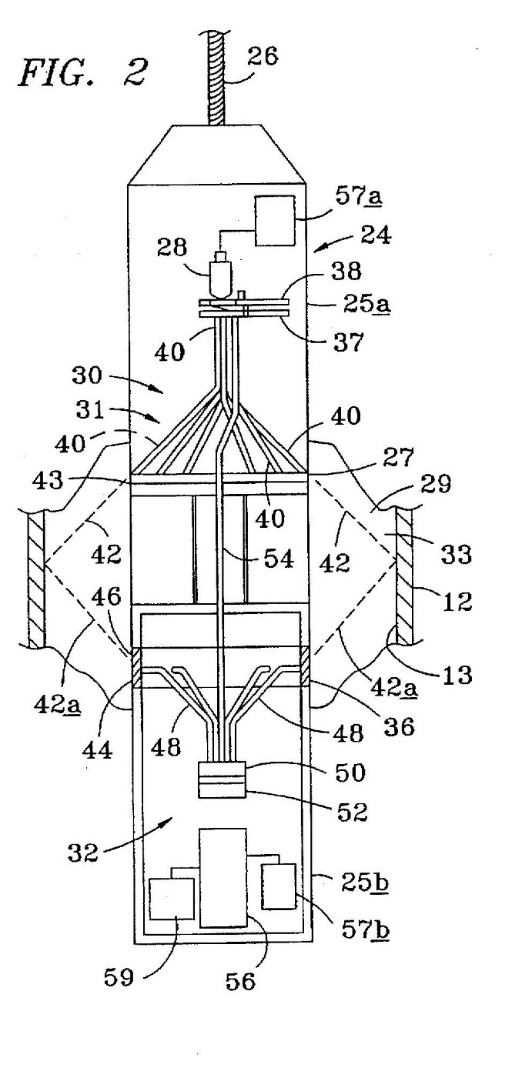

[435] | |

[437] | |

[438] | |

[440] | |

[441] | |

[455] | |

[471] | |

[472] | |

[472] | |

[476] | |

[516] | |

[520] |

1 Globaltech Corporation Pty Ltd contends that Reflex Instruments Asia Pacific Pty Ltd has infringed Globaltech’s Australian Standard Patent No 2012297564 for the invention titled “Optical device for use with downhole equipment” (the patent). Reflex admits that it has infringed the patent by supplying in Australia downhole survey instruments under the brand names “EZ-GYRO” and “EZ-TRAC”, when such instruments are supplied with optical devices as claimed in claim 1 of the patent and described by Reflex as the “IRDA Device” and the “IR Coupling” (“IR” meaning infrared, and “IRDA” referring to the Infrared Data Association Standard). However, Reflex also contends by its cross-claim that the patent is invalid for lack of novelty and lack of inventive step.

2 I consider that Reflex has not established that the invention as claimed in the patent is invalid for lack of novelty or lack of inventive step. In summary:

(1) the three prior art documents (referred to as Iizuka, Bergren, and Sun) do not anticipate the invention as claimed in the patent for numerous reasons in each case and, accordingly, do not deprive the claimed invention of novelty; and

(1) the inventive step in the present case was the perception and the related idea at the priority date that existing downhole tools could be improved by an arrangement that enabled the light signal within the optical device to be reflected to an infrared communication port on the side of the instrument housing, which would mean that when the instrument was brought to the surface for data communication, the end of the housing did not need to be uncoupled to enable access to the infrared port for the data to be obtained, as it could be communicated from the side port to a hand-held communication device. This perceived capacity for a material improvement to existing devices was not obvious at the priority date. While the method chosen to effect this improvement would have been obvious to a person skilled in the art who had been asked to make that particular improvement at the priority date, there was no such problem perceived with the existing designs and no need felt to improve the designs in this or any similar manner. The inventiveness of the perception and related idea to improve the existing designs in this or some similar manner is sufficient to sustain the inventive step of the invention as claimed.

3 The claimed priority date of the patent is 15 August 2011.

4 The inventors are Gordon Stewart and Michael Klass, both current directors of Globaltech.

5 The field of the invention relates to “devices enabling data to be transmitted to and from downhole equipment, such as core orientation units and borehole telemetry probes”: p 1 [0001].

6 The background to the invention at pp 1–2 explains that:

[0002] Core orientation is the process of obtaining and marking the orientation of a core sample from a drilling operation.

[0003] The orientation of the sample is determined with regard to its original position in a body of material, such as rock or ore deposits underground.

[0004] Core orientation is recorded during drilling, and analysis is undertaken during core logging. The core logging process requires the use of systems to measure the angles of the geological features, such as an integrated core logging system.

[0005] Whilst depth and azimuth are used as important indicators of core position, they are generally inadequate on their own to determine the original position and attitude of subsurface geological features. Core orientation i.e. which side of the core was facing the bottom (or top) of a borehole and rotational orientation compared to surrounding material, enables such details to be determined.

[0006] Through core orientation, it is possible to understand the geology of a subsurface region and from that make strategic decisions on future mining or drilling operations, such as economic feasibility, predicted ore body volume, and layout planning.

[0007] In the construction industry, core orientation can reveal geological features that may affect siting or structural foundations for buildings. Core samples are cylindrical in shape, typically around 3 metres long, and are obtained by drilling with an annular hollow core drill into subsurface material, such as sediment and rock, and recoverying [sic] the core sample.

[0008] A diamond tipped dril [sic] bit is used at the end of the hollow drill string. As the drill progresses deeper, more sections of hollow steel drill tube are added to extend the drill string. An inner tube assembly captures the core sample. This inner tube assembly remains stationary while the outer tubes rotate with the drill bit. Thus, the core sample is pushed into the inner tube.

[0009] A ‘back end’ assembly connects to a greaser. This greaser lubricates the back end assembly which rotates with the outer casing while the greaser remains stationary with the inner tubing.

[0010] Once a core sample is cut, the inner tube assembly is recovered by winching to the surface. After removal of the back end assembly from the inner tube assembly, the core sample is recovered and catalogued for analysis.

[0011] Various core orientation systems have previously been used or proposed. Traditional systems use a spear and clay impression arrangement where a spear is thrown down the drill string and makes an impression in clay material at an upper end of the core sample. This impression can be used to vindicate the orientation of the core at the time and position the spear impacted the clay.

7 The patent explains that prior art devices have limitations, including that (at p 3 [0015]):

…The orientation unit is connected to the greaser by a screw thread and o-ring seal arrangement. In the harsh down hole environment within the drill string, it has been realised that the o-ring seals are not always effective and can let fluid into the space between the orientation unit and the greaser.

8 Further, “the orientation unit must be disassembled from the greaser unit before the display and orientation unit can be viewed, rotated and the required core orientation displayed”: p 4 [0015]. It then states (p 4):

[0016] Similar issues arise with downhole probes that are used to obtain borehole telemetry data to determine drilling progress, such as depth and direction of the borehole and change in surrounding magnetic field.

9 At p 4 [0017] the patent records that:

Typically the downhole equipment is brought to the surface once sufficient data is gathered or task completed, such as obtaining a core sample. It is common practice to manually have to separate the backend assembly from an electronics package used for gathering downhole data. This task involves unscrewing the backend assembly from the electronics package, which takes time and risks thread damage as well as resulting in risk of ingress of dirt and water into the thread. Also, o-ring seals protecting the electronics unit may be compromised through separation and refitting of the backend assembly and electronics unit. Similar issues exist with separating the electronics unit of a downhole probe from its backend assembly.

10 Page 4 [0018] says:

It has been found desirable to provide means of obtaining signals/data from or providing signals/data to downhole equipment electronics units, such as used in core sample orientation units or downhole probes.

11 The background to the invention section ends with this statement (p 5 [0020]):

With this in mind, it has been found desirable to provide improved means for obtaining signals/data from or providing signals/data to an electronics unit of downhole equipment.

12 The summary of the invention in the patent includes at p 5 [0021]:

With the aforementioned in mind, in one aspect the present invention provides a device that transfers at least one electromagnetic signal to or from an electronics unit of downhole equipment, the device including a body and an electromagnetic signal direction altering means, the body having a light path arranged to allow the electromagnetic signal from an electromagnetic wave source associated with the electronics unit to pass to the electromagnetic signal direction altering means, the electromagnetic signal direction altering means causing the electromagnetic signal to change direction of travel, the device, in use, configured to transmit or receive the electromagnetic signal through at least one aperture through a side wall of a component of downhole equipment.

13 At pp 7–9 the summary records that:

[0037] An advantage of the present invention is that the greaser or other equipment to which the electronics unit attaches does not need to be separated from the electronics unit in order to obtain access and communicate with the device to obtain data. This avoids needing to unscrew components of the downhole equipment and risk ingress of dirt/water or damaged threads, as well as reduces time taken to obtain data.

[0038] In addition, the electronics unit can be started or stopped remotely and at the most opportune time. For example, in known devices an operator usually delays turning on the electronics unit until the last minute in order to conserve the unit's onboard battery power. The operator then starts the electronics unit and assembles the unit to the other equipment, such as a greaser or probe assembly.

[0039] The present invention avoids the need for such urgent activity by allowing an operator to switch the unit on or off by sending an optical signal from a hand held device to the optical device through an overlying aperture, the device then transmitting the optical signal to the electronics unit to activate/deactivate the unit. Data to/from the unit can also be sent/received utilising the same optical device.

…

[0042] A further aspect of the present invention provides downhole equipment having an electronics unit configured to obtain data relating to a borehole into which the electronics unit is inserted or to obtain data relating to equipment used within the borehole system, and an optical device associated with the electronics unit, and an optical device according to any one of the preceding claims configured to enable optical signals to be transmitted to or received from the electronics unit whilst the electronics unit is connected to the downhole equipment.

14 At p 9 [0044] the summary records:

A still further aspect of the present invention provides a downhole data gathering system, including a communication device arranged to communicate wirelessly with an electronics unit of downhole equipment, the downhole equipment including an electronics unit configured to obtain data relating to a borehole into which the electronics unit is inserted or to obtain data relating to equipment used within the borehole system, and a device that transfers electromagnetic signals to or from the electronics unit of the downhole equipment, the device including a body and an electromagnetic signal direction altering means, the body having a light path arranged to allow the electromagnetic signals from an electromagnetic wave source associated with the electronics unit to pass to the electromagnetic signal direction altering means, the electromagnetic signal direction altering means causing the electromagnetic signal to change direction of travel and wherein the device is configured to enable the electromagnetic signals to be transmitted to or received from the electronics unit whilst the electronics unit is connected to the downhole equipment, the device enabling transmission of the electromagnetic signals from the electronics unit to the wireless communication device, or from the wireless communication device to the electronics unit, through at least one aperture in a side wall of the downhole equipment.

15 The patent includes the following figures described in a section entitled “Description of the preferred embodiment” (p 10):

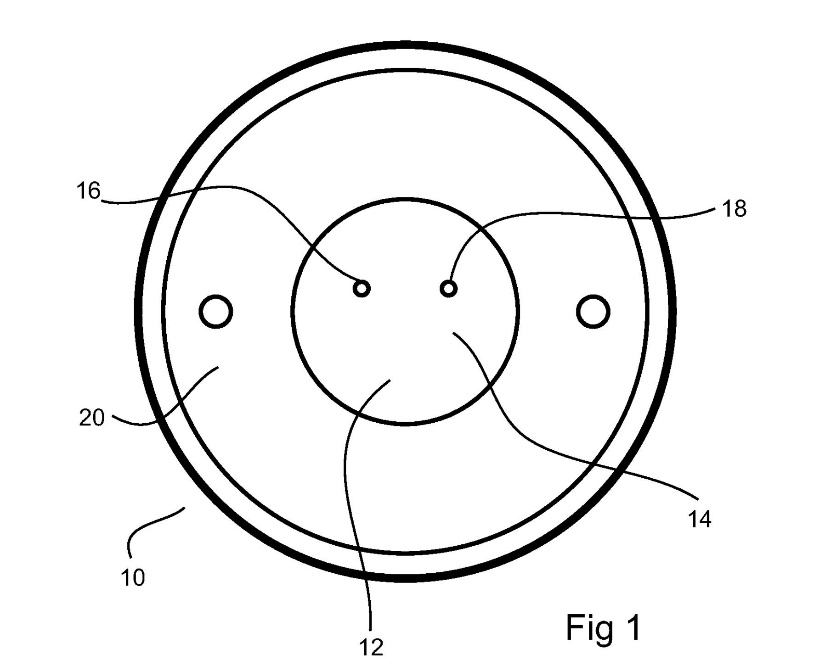

16 Figure 1 shows an end on view of a core sample orientation device or downhole probe having an indicator window whereby indicator lights provide optical signals to an optical device according to an embodiment of the present invention: p 10 [0047]. In figure 1, the indicator window end 12 of an electronics unit of a core sample orientation data gathering device 10 includes a window 14. Indicator lights 16, 18 can be seen through this window at least when illuminated. The window end is sealed by a retaining plate 20: p 10 [0051].

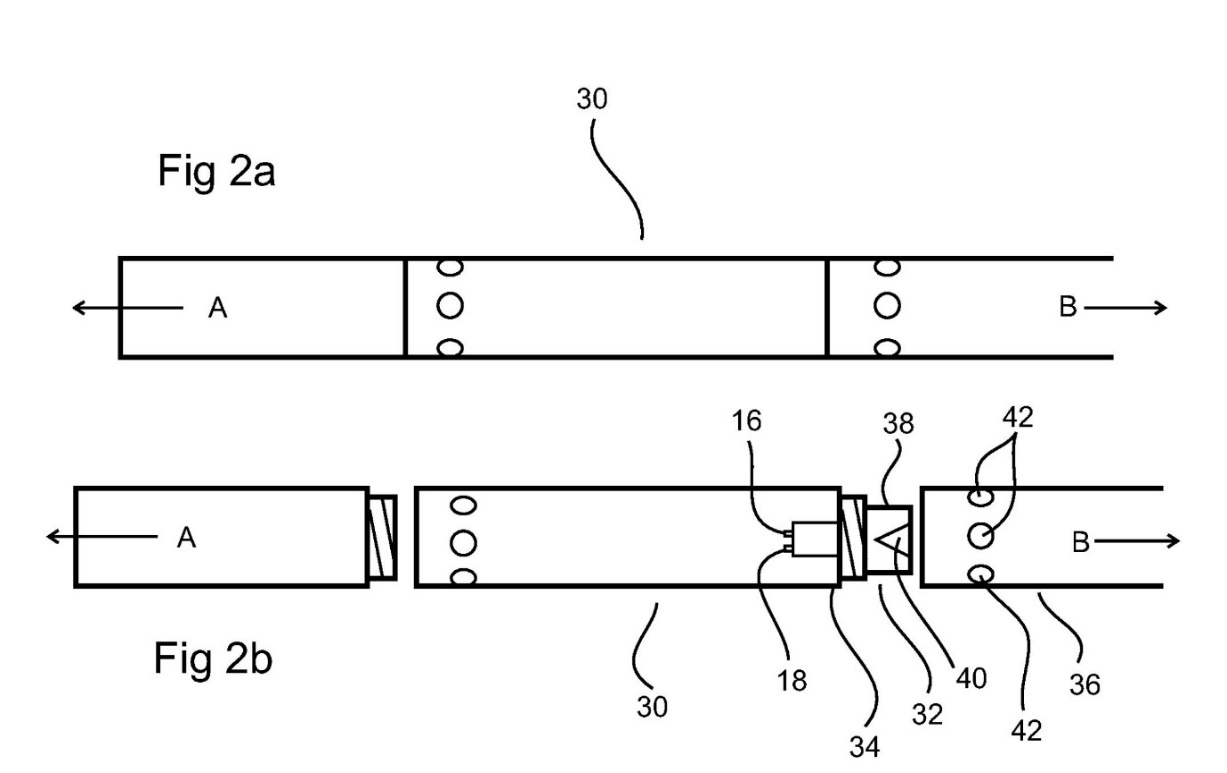

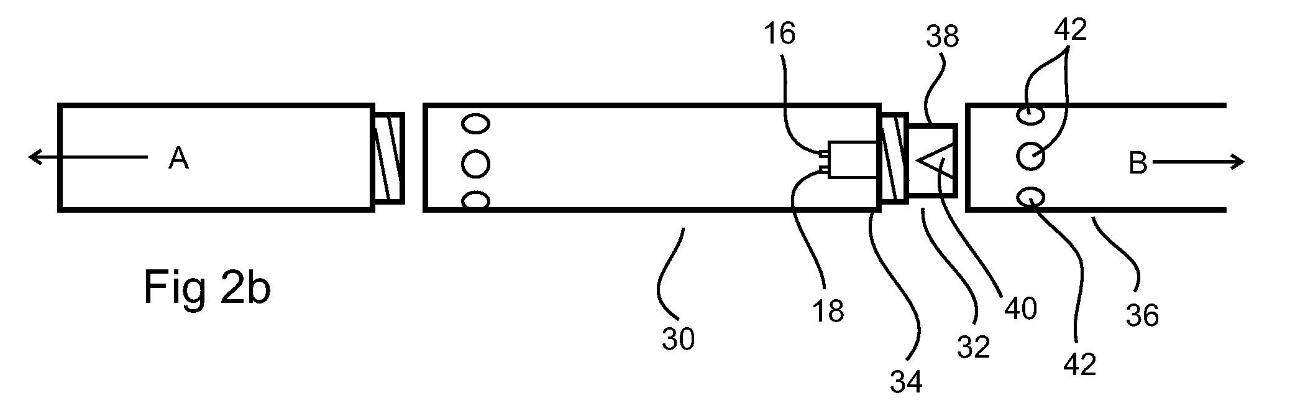

17 Figures 2a and 2b below show an electronics unit 30 for gathering data downhole which houses the light emitters 16, 18. Light from these emitters (eg, LEDs,or light emitting devices) passes through the window 14 (shown in figure 1). Reference arrow A refers to the drill bit end direction, and reference arrow B refers to the backend assembly direction. An optical device 32 according to an embodiment of the present invention is provided at the end 34 of the electronics unit 30 and which device extends into the greaser unit 36 of the backend assembly when connected thereto. The optical device has a body 38 and a light path altering means 40. The body also defines a light path therethrough (see figure 3 below) arranged to allow the optical signal from a light source(s) 16,18 associated with the electronics unit to pass to the light path altering means. The light path altering means 40 can be arranged to cause the optical signal from/to the electronics unit to change direction of travel and emit out of the body/into the body of the optical device. The greaser unit 36 has apertures 42 that allow light therethrough. Light from the emitters is directed onto at least one light path altering means of the device. The emitted light can be observed through the apertures 42 in the greaser: pp 11–12 [0058]–[0064].

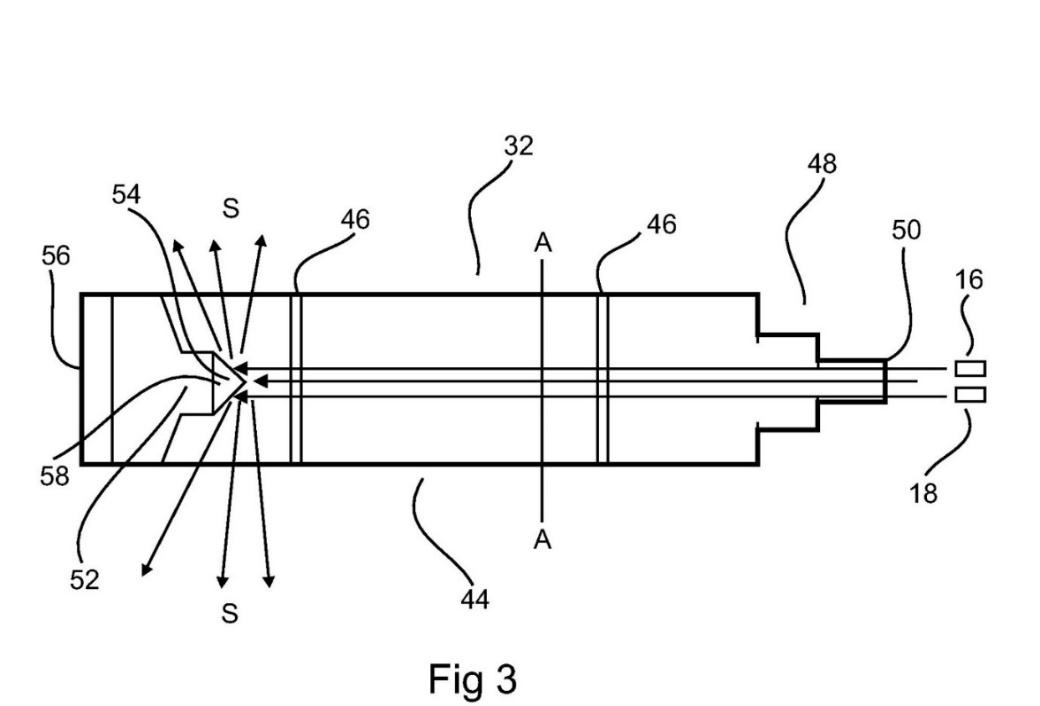

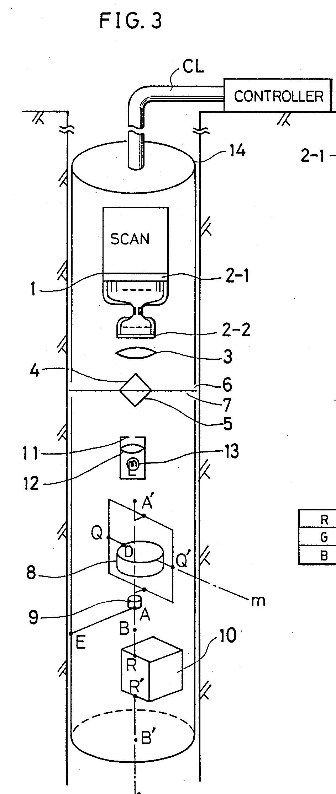

18 Figure 3 below shows a particular embodiment of an optical device 32 for use with a downhole electronics unit. The optical device is shown in side, profile view. In practice, the device is cylindrical in cross section A–A. The optical device has a body 44 of a transparent machined plastics material, such as polycarbonate, acrylic, nylon etc. Glass may also be used, though a plastic material is preferred. The body has annular grooves 46 therearound to receive o-rings for sealing the device within a housing or casing of a downhole unit, such as an electronics unit. In this embodiment, the transparent material of the body allows light to pass therethrough. At least a portion of the body is shaped to fit within a housing or casing of a component of downhole equipment, such as an electronics unit or a greaser unit or extension piece etc. A first end 48 of the body is shaped so that an end surface 50, in use, faces the light emitters 16, 18 or other light emitters depending on the equipment used and required application. Light from one or more such emitters is transmitted by the light path through the body to impinge on a light path altering means 52. In this embodiment, the light path altering means includes a reflector 54. The reflector reflects some or a majority of the light impinging upon it, and said reflected light is re-directed sideways (S) with respect to a longitudinal direction (L) of the device. The light path altering means may be provided, as in this embodiment, by forming a recess in its second end 56. The recess may form a conical surface 58 to which a reflective material is applied, such as a silvery coating: pp 14–15 [0071]–[0077].

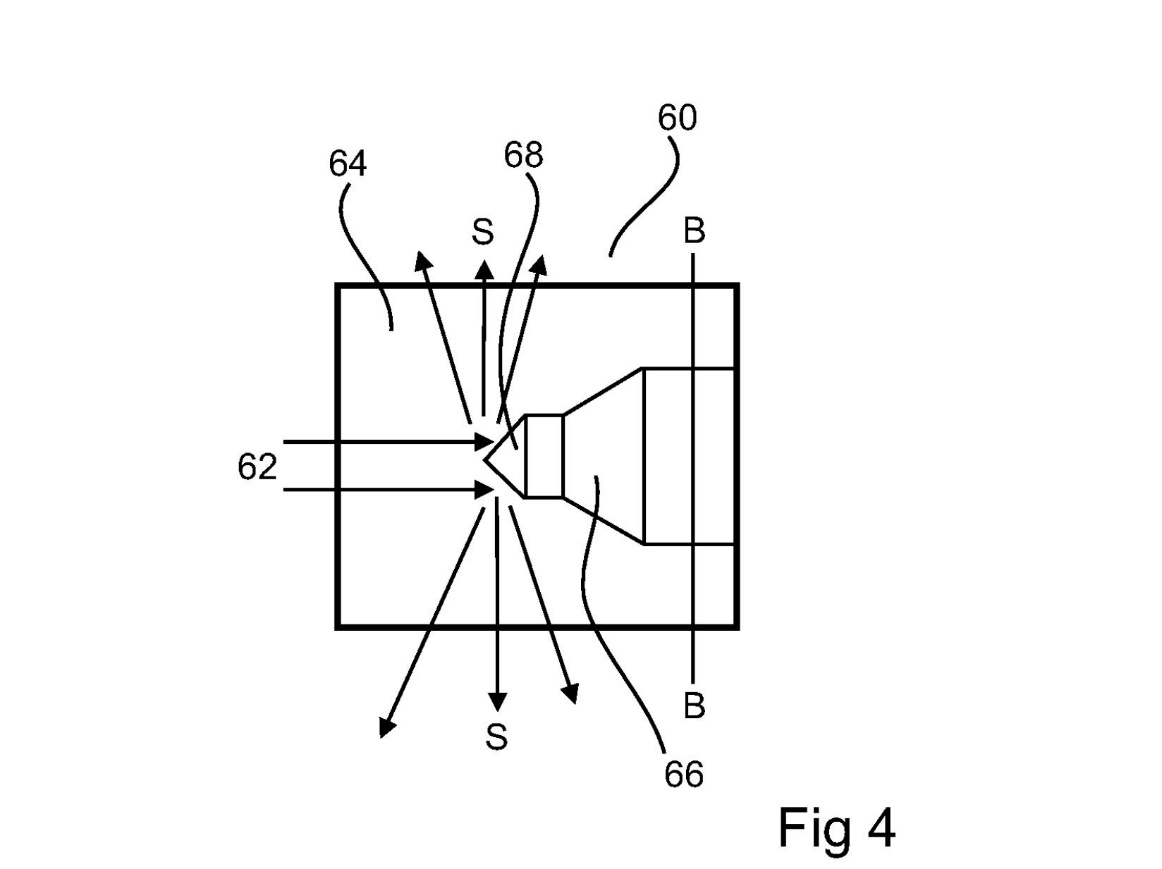

19 Figure 4 below shows an alternative embodiment of the present invention which works in the same manner as that of figure 3. This alternative form of optical device 60 is provided as an insert for use with a downhole probe. Again, this device as the one above in figure 3, is shown in side view but is a cylinder with a circular cross section B–B. Light 62 entering the device 60 passes through the body 64 material and reflects off of a protrusion 66 into the envelope of the cylinder. The protrusion is a machined surface coated from the exterior with a reflective material. A conical surface 68 assists in diffracting light sideways (S). The light path altering means may be a dished or domed end to the device and which is coated or covered in a reflective material. The optical device can be inserted into a downhole component and removed from replacement or access to an end of the electronics unit as required. Otherwise, the optical device can be left in situ to transmit light from/to the electronics unit. This can avoid the need to disassemble the electronics unit from the backend assembly, greaser unit or probe etc to which it is connected. The electronics unit can be switched on or off by sending a controlling optical signal to the electronics unit through the optical device. The optical device may be formed of one or multiple parts. For example, the optical device may be machined as a monolithic component or may be formed of multiple sub-components brought together, which may be bonded together or simply abutting in use. Light impinging on the light path altering means can be emitted sideways omni-directionally. Thus, and of great benefit to an operator, the optical device needs no alignment with the at least one aperture of the downhole assembly through which the light is to be transmitted: pp 15–16 [0078]–[0085].

20 The claims in contest are claims 1, 5, 7, 8, 9, 10, 12, 17, 21, 22, 24, 25, 26, 27 and 29.

21 Claim 1 in the patent is to:

A device that transfers at least one electromagnetic signal to or from an electronics unit of downhole equipment, the optical device including a body and an electromagnetic signal direction altering means, the body having a light path arranged to allow the electromagnetic signal from an electromagnetic wave source associated with the electronics unit to pass to the electromagnetic signal direction altering means, the electromagnetic signal direction altering means causing the electromagnetic signal to change direction of travel, the device, in use, configured to transmit or receive the electromagnetic signal through at least one aperture through a side wall of a component of downhole equipment.

22 Contested claims 5, 7, 8, 9, 10, 12, and 17 are dependent on claim 1.

23 Claim 21 is to:

A downhole data gathering system, including a communication device arranged to communicate wirelessly with an electronics unit of downhole equipment, the downhole equipment including an electronics unit configured to obtain data relating to a borehole into which the electronics unit is inserted or to obtain data relating to equipment used within the borehole system, and device-that [sic] transfers electromagnetic signals to or from the electronics unit of the downhole equipment, the device including a body and an electromagnetic signal direction altering means, the body having a light path arranged to allow the electromagnetic signals from an electromagnetic wave source associated with the electronics unit to pass to the electromagnetic signal direction altering means, the electromagnetic signal direction altering means causing the electromagnetic signal to change direction of travel and wherein the device is configured to enable the electromagnetic signals to be transmitted to or received from the electronics unit whilst the electronics unit is connected to the downhole equipment, the device enabling transmission of the electromagnetic signals from the electronics unit to the wireless communication device, or from the wireless communication device to the electronics unit, through at least one aperture in a side wall of the downhole equipment.

24 Contested claims 22, 24, 25, 26, 27, 28 and 29 are dependent on claim 21.

25 Kelvin Brown is the Global Lead (Directional Drilling) of Reflex. Reflex is a wholly owned subsidiary of Imdex Ltd (Imdex). He has over 20 years’ experience in mineral exploration drilling. He has acquired knowledge and experience in all major aspects of exploration drilling, including auger drilling, rotary-percussion drilling and diamond core drilling, and the downhole equipment and instruments used in those drilling programmes. He regularly observed competitors’ products being used on Reflex customers’ sites and was given an opportunity to operate them. He also maintained a familiarity with competitors’ products by attending mining events, doing online research on competitors’ websites, LinkedIn and social media accounts, via customer contacts who would inform him of competitors’ products, through marketing collateral including mining and geology publications and by way of membership with the Deep Exploration Technologies Cooperative Research Centre (DETCRC).

26 Mr Brown said that downhole equipment refers to equipment used down boreholes, which includes core orientation tools and survey tools.

27 Mr Brown identified that the Imdex range of instruments being manufactured in Western Australia as at 30 June 2011 comprised: (a) ACT II RD – rapid descent core orientation instrument, (b) EZ-SHOT – single shot magnetic survey instrument, (c) EZ-AQ – magnetic survey instrument specifically designed for AQ sized boreholes, (d) EZ-TRAC – multi shot magnetic survey instrument, (e) MAXIBOR II – optical non-magnetic survey instrument, (f) Reflex Gyro – gyroscopic survey instrument, and (g) customised directional motors.

28 Mr Brown said that with the exception of the EZ-SHOT and the customised directional motors, each of the above instruments used wireless handsets for communication and data transmission. The ACT II RD, EZ-AQ, EZ-TRAC and MAXIBOR II used wireless infrared communication. The Reflex Gyro used Bluetooth communication.

29 According to Mr Brown, core orientation tools and survey tools are complementary products. The borehole used in the core orientation process is required to be surveyed at some point in order to determine the geospatial position of the oriented core. The survey process is undertaken either before or after the process of orientating the core. Core orientation tools are used to indicate the orientation of a core sample in its original underground location and provide that orientation data to the operator. Survey tools are primarily used to measure changes in inclination and azimuth (deviation) along a drill hole. It is typical for drilling rig operators to require supply of both core orientation tools and survey tools before commencing drilling operations.

30 Core sample orientation is the process of obtaining and marking the orientation of a core sample from a drilling operation, which is typically an approximately three metre length of solid cylindrical core. Core orientation procedures are required to be carried out because, once detached from its parent rock and retrieved to the surface, the recovered sample will not reflect its original orientation underground. In order to re-orientate the sample, it is typically necessary to include an orientation tool in the drilling assembly unit between the greaser unit and inner core tube holding the core sample. The purpose of the orientation tool is to indicate the orientation of the core sample in its original underground location and provide that orientation data to the operator.

31 The process of orientating drill samples allows geologists to correlate recovered samples with one another to reveal trends in rock strata and predict whether resource mining is worthwhile, and if so, where, in what direction, and how deep below the surface. Core orientation is an important process as it allows geologists to build a three-dimensional profile of subsurface resource deposits, such as iron ore or diamonds. As metal-bearing deposits are often determined by the structural compositions of their enclosing rocks, it is important for the geologist to understand these structural elements in order to estimate the likely location of mineral bearing ore deposits, and once located, determine the likely position, size and composition of the deposit. If a valuable ore seam is found, it is vital that the core has been orientated properly so that a true picture of the ore body can be investigated, located and estimated.

32 Prior to and/or during any drilling operation, there is often a need to obtain more information from the borehole being drilled, as boreholes frequently deviate from the projected path. As such, there is a need to know in which direction the hole is on/off track and by how much, and if the course should be re-routed. A downhole or borehole survey is therefore a geophysical survey carried out by a specialised technician which involves putting digital geophysical equipment down exploration drill holes to gather magnetic, radiometric or electrical information from the rocks adjacent to the hole.

33 The geologist will have plotted the desired trajectory of the drill path before the coring operation begins. After the drill hole has sufficiently advanced, the geologist will direct the drilling crew to lower a survey instrument into a desired location of the borehole to ensure that the drill path has not deviated from its planned trajectory.

34 Downhole survey data provides geospatial data, namely the dip and azimuth of the axis of the core, which can then be used by a driller. However, downhole survey data does not provide orientation information to fully orientate the cylindrical sample of the core.

35 The following sections primarily consist of extracts from Professor Tapson’s affidavit evidence, relied on by Reflex.

36 Jonathan Tapson is an electrical and electronic engineer. He was a Professor of Electrical and Electronic Engineering at Western Sydney University and became Visiting Professor of Electronics and Information Technology at the University of Technology, Sydney. He has worked as the Chief Scientific Officer for GrAI Matter Labs in San Jose, California. He holds a PhD in Engineering from the University of Cape Town, obtained in 1994. He has 32 years of experience in electrical and electronic engineering, primarily in the field of sensors and instrumentation. This includes designing and building orientation systems for the mining and resources industry, including in drilling applications.

37 Professor Tapson has previously been engaged on behalf of Reflex in the following proceedings: Australian Mud Company Pty Ltd v Coretel1 Pty Ltd (No 4) [2015] FCA 1372, Australian Mud Company Pty Ltd v Coretell Pty Ltd (No 2) [2018] FCA 1109; (2019) 134 IPR 359, Australian Mud Company Pty Ltd v Globaltech Corporation Pty Ltd [2018] FCA 1839; (2018) 138 IPR 33, Reflex Instruments Asia Pacific Pty Ltd v Borecam Asia Pte Ltd [2017] APO 51, Reflex Instruments Asia Pacific Pty Ltd v Minnovare Pty Ltd [2018] APO 70, and Reflex Instruments Asia Pacific Pty Ltd v Minnovare Pty Ltd [2018] APO 71. He has also been engaged by the respondent in two ongoing matters, one in the United States (by a related Imdex subsidiary) and one in Australia in this Court.

38 Professor Tapson is a named inventor of a number of patents including two patent applications filed by the respondent, being: (a) Australian provisional application 2016905363 (363 application) in the name of Imdex Global BV filed on 23 December 2016, and (b) Australian standard patent application 2017381411 (411 application) in the name of Reflex Instruments Asia Pacific Pty Ltd (formerly Imdex Global BV) filed on 22 December 2017 which claims priority from the 363 application. Professor Tapson was not aware of these applications before they were filed and was first informed about them in around August 2017. He has no contractual or financial connection with Reflex or its related companies other than his remuneration to act as an expert in the various proceedings identified and has not been remunerated for his inventive contribution to the 363 and 411 applications.

39 Before being provided with the patent, Professor Tapson was informed that the patent in dispute related to downhole instrumentation used in the mining industry, including techniques for data transmission. He was asked to complete a design task based on only the common general knowledge in the field described as “the methods for communicating and transmitting data in devices which are designed to operate in a geological drilling environment” at the priority date of August 2011. After completing the design task he was provided with the patent.

40 Professor Tapson referred to the resources relevant to the identified field that he and colleagues would have had access to, and consulted as at the priority date. He and colleagues in the field regularly attended instrument, measurement and position-sensing conferences. They also read and referred to papers delivered at these conferences. They regularly read and referred to other papers in peer-reviewed journals, trade journals and industry-specific journals. He has also reviewed patents since the early 2000s. He considered it common for people working in the field to use patent databases and specifications as a resource to assess technology and the commercial risks associated with particular designs. He and his colleagues engaged with industry representatives including geophysicists and drilling operators in relation to the design of mining instrumentation. They also regularly reviewed information about sensors, downhole instruments and componentry (including specifications, data sheets, user guides and operational manuals) published by suppliers of such products and componentry. They monitored internet forums provided by product and componentry suppliers, on which instrumentation systems and componentry information and knowledge were disseminated and exchanged.

4.1.3 Common general knowledge

41 Professor Tapson said that the common general knowledge (as he was instructed, the background knowledge and experience which is available to all in the field) at the priority date included that downhole instruments are tools that are used down boreholes. These tools include survey tools, core orientation tools, drilling tools, geophysical probes and gyroscopes. Survey tools and core orientation tools are usually both present at drilling sites and are often used in tandem in drilling operations.

42 A core orientation tool is one that provides information as to the orientation of a core sample drilled from a borehole. Core orientation does not generally require a measurement of azimuth or direction.

43 A survey tool is a tool that provides information to plot a borehole trajectory and path, usually including azimuth and direction and usually using a compass or a gyroscope or other deviation methods.

44 Since the 1990s, there has been a continuing evolution towards digitisation of these tools. By the 2000s, the use of electronic tools downhole started to overtake the use of pre-existing mechanical methods. This development was accompanied by the use of new methods of communication to extract data obtained by these tools downhole once back at the surface. This was a trend not only in downhole tools but in all areas of industrial automation around this time.

4.1.3.2 Wired systems for communicating and/or transmitting data downhole

45 The available options included:

(1) Electrical port on the instrument housing: this option involved placing a sealed waterproof and pressure-proof electrical port on the external housing of the downhole instrument. In particular, the instrument would be sealed at the surface in an external housing and sent downhole to gather data. The data could then be read after the downhole instrument had returned to the surface or alternatively, the instrument could be removed or partially unsealed from the housing. This method had two disadvantages. The first is that waterproof and pressure-proof electrical ports were not particularly reliable in the drilling environment. The second is that unsealing and re-sealing a port or housing seal introduced a delicate and potentially unreliable action into a busy and robust workflow. Introducing such a step in a drilling workflow created a likely point of failure, which could be expensive should the instrument be flooded after seal failure.

(2) Electrical conductor on the drill string: this option involved placing a conductor in the metal drill string or using the metal of the drill itself as an electrical conductor. There were a number of so called single-wire techniques for using a single conductor to transmit data. He was aware of a number of efforts to use this method as at the priority date, but not aware of any that was particularly reliable or allowed a high data rate.

(3) Permanent cable integrated into an instrument: this option involved integrating a permanent connection between the instrument and drill string. In such a design the instrument and drill string would have a permanent multi-wire communications cable integrated into it. While electronically satisfactory, this was unlikely to prove viable for reasons of cost, complexity and reliability in geological drilling.

46 The available options included:

(1) Acoustic systems: acoustic systems cover a wide range of possibilities, including transmission by pulses in liquid, and acoustic and ultrasonic transmission in air and water. The early reliable logging while drilling (LWD) devices created pulses in the drilling fluid (mud) being pumped from the surface. These pulses were readable at the surface as pressure pulses at the mud pump. This method is called mud-pulse telemetry.

(2) Ultrasonic transducers: a second acoustic possibility is to use ultrasonic transducers to communicate from within the housing to the exterior (at the surface). Ultrasonic communication was well established as a method for underwater communication between sealed vessels at least 50 years ago. Each device in the transmission will have a small ultrasonic transceiver (which can be thought of as a combination of speaker and microphone, operating at inaudible frequencies). The transmitter will broadcast the data as modulated sounds, and the receiver will receive the data as a sound stream and decode it. An advantage of ultrasonic links is that ultrasound in sufficient volume penetrates through most solids and liquids for a moderate distance, and hence can be transmitted from inside a housing without breaking the seal. There were many variations on these methods.

(3) Optical devices: the use of optical systems to bridge gaps which are not tractable with electrical conductors is a mature art, with optocouplers, photocouplers and opto-isolators being commonplace in electronics since the semiconductor boom of the 1970s. While much of the technology focuses on guided optical transmission (eg, through optic fibres) there is an entire field of electronics that focuses on unguided transmissions (ie, where there is no bespoke optical system connecting the transmitter and receiver, and transmissions take place through whatever natural medium lies between the two systems). This is called optical wireless communication. It was largely a fringe technology until the invention of the IRDA standard in the early 1990s, at which point it became commonplace – including use in television remote controls and similar devices for short range communication. The advantage of optical wireless communication is that the electro-optical devices that transmit and receive light can be placed behind a clear pressure-proof window, which will not significantly distort or disrupt short range communications.

4.1.3.4 Magnetic Communication

47 Magnetic communication or strictly, near-field magnetic induction communication, makes it possible to transmit information by means of a modulated magnetic field. This is quite straightforward and is not very different from wireless communication.

48 Magnetic communication has the advantage that magnetic fields are not significantly attenuated in water or soil or other dielectric media, so has often been used as a means of underwater communication (to submarines, for example). It is possible to fabricate magnetic antennas which are robust enough to be integrated into the exterior of a pressure housing, as they consist of coils of wire which can be deeply embedded in a protective epoxy, for example.

49 The disadvantage for all magnetic communication and instruments is that they are each susceptible to interference from man-made or natural magnetism which will interfere with the communication and result in incorrect measurements. Additionally, magnetic communication has the disadvantage that unless a very high-power signal is transmitted, it is only effective over short range, and because of the intrinsic inductance of magnetic antennas, it is not possible to sustain a high data rate with magnetic communication.

4.1.3.5 Handsets or hand-held devices

50 A wireless communication system would typically use an interface such as a handset or hand-held device to communicate with the downhole instrument. The use of hand-held devices to display orientation information or measurements from sensors and instruments was increasingly common amongst mining engineers and surveyors before the priority date particularly with the introduction of the Apple iPhone in 2007.

51 The Apple iPhone was increasingly used as a hand-held human-machine interface (HMI). HMIs include the keyboard, or mouse, and display which are used to interact with any given machine. Mining survey instruments started to include a remote display (via HMI) for various reasons including (a) safety: often the sensor or instrument must be placed in a position, such as closely adjacent to a rotating machine shaft, that would be hazardous for a human operator. Under these circumstances, the use of a remote display makes the instrument safe to use. Also, in hazardous environments where the presence of flammable gas or powders create a risk of explosion, it is often safer to keep electronic instruments within their sealed explosion-proof housings and interrogate them wirelessly with a remote display, (b) accommodation: the volume of space available to house the instrument may not be sufficient for a human operator, or access may not be possible (for example, the interior of a drill pipe), (c) ergonomics: in some cases, the instrument may be placed in a position which is either uncomfortable for the operator, or does not allow them to access the controls which they require to make use of the instrument information, and (d) workflow: a wireless remote enables the operator to work more quickly because there is no need to remove or access the instrument, which might cause lost drilling through downtime.

4.1.4 Designing a downhole instrument for transferring data

52 Professor Tapson described the steps he would have taken to design a downhole instrument for transferring data based on the common general knowledge at the priority date.

53 Professor Tapson identified the factors that had to be considered in the design as being the hostile borehole environment from liquid and very high pressure. Accordingly, the downhole instrument must be waterproof at the depth to which it is anticipated the drill will go. Other design issues include: (a) at drilling depths, the ambient temperature can be extremely high, which can affect the performance of polymer seals as well as electronics, (b) the drilling environment is extremely harsh physically (ie, involving being dropped onto hard surfaces from a significant height), and (c) if the instrument is to be integrated into the drill string for any kind of operation during or concurrent with borehole drilling, it will be physically isolated from the outside by the metal structure of the drill string into which it is integrated.

54 For these reasons, downhole instruments are generally placed in housing designed to protect the instrument while still allowing it access to the external environment for communications and sensing purposes. Communicating between an instrument in a sealed housing and an external device was well-known before the priority date. These methods included either use of wired devices or systems (meaning there is at least one physical electrical conductor connecting the instrument and the external device) or wireless devices or systems (which are similarly divided into multiple classes according to the medium of communication).

55 There are two possible requirements (purposes) of downhole instruments intended for communicating or transmitting data to and from the surface: (a) first, to communicate from the instrument to the surface while drilling (measurement while drilling (MWD) or LWD), and (b) secondly, to communicate between a housed instrument and another device at the surface.

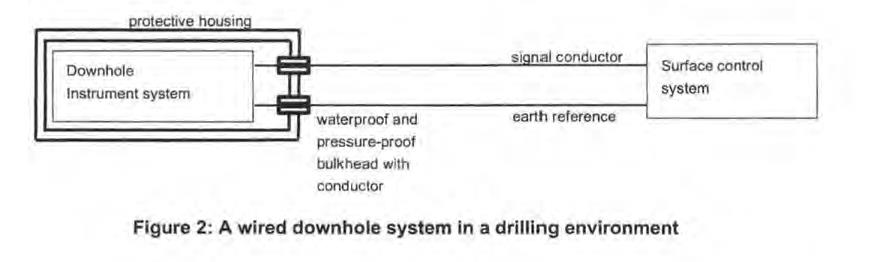

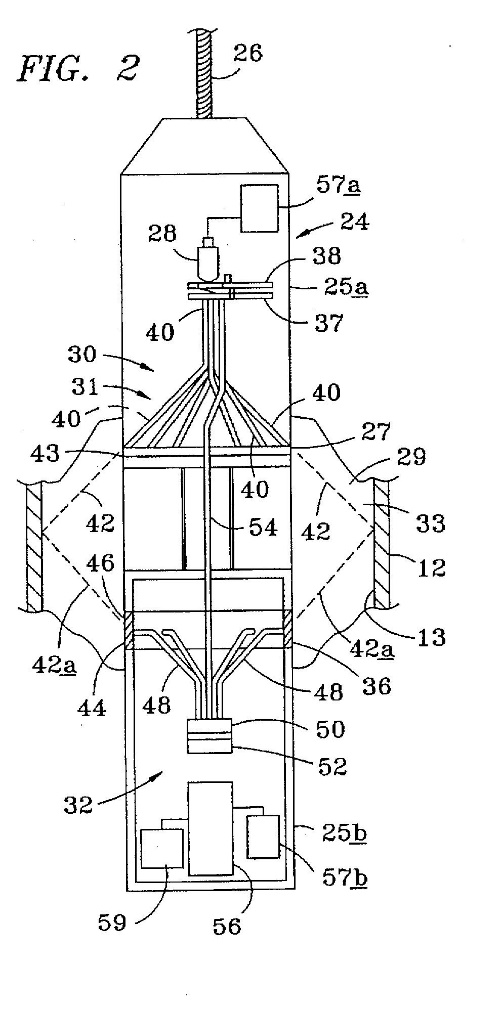

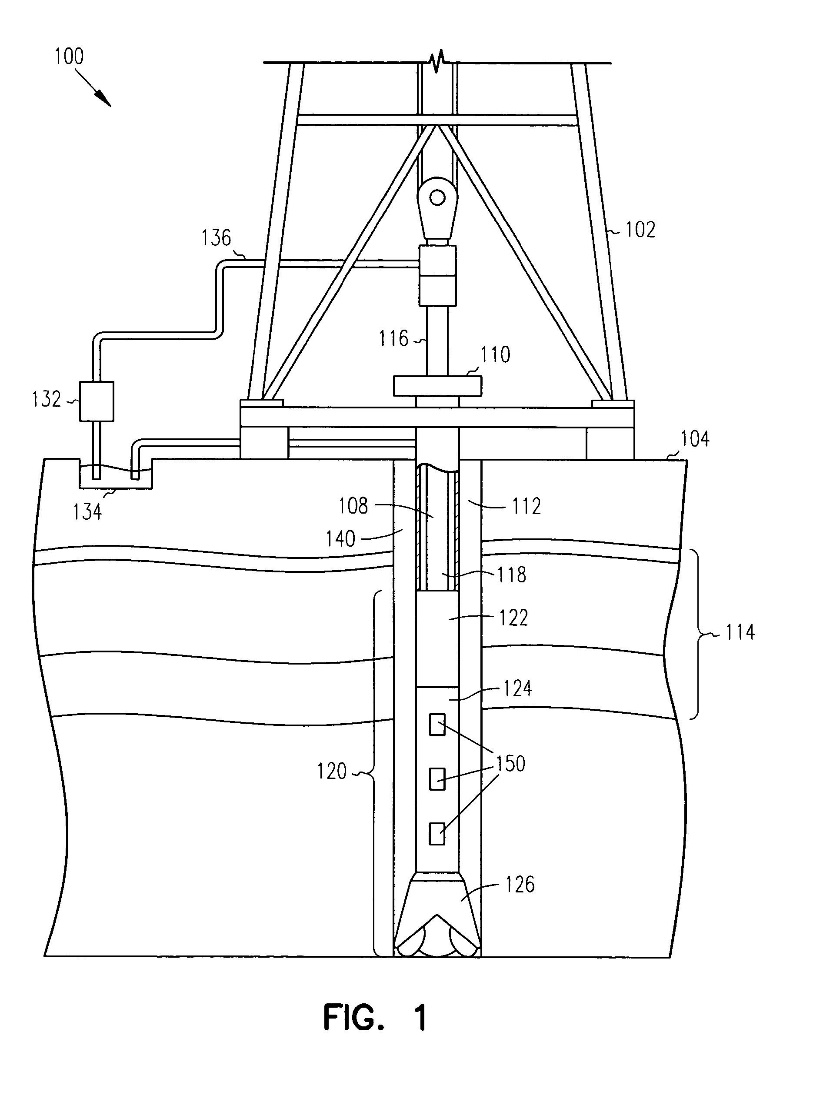

56 Professor Tapson would have preferred a wireless communication method over a wired communication method. A wired downhole system has many disadvantages. Even with good conductors (a drill string and the rock body are not good conductors) the transmission rate is low, because data going in both directions must share the same signal line. This is called half-duplex communication and is not efficient. The signal lines must somehow be connected to the downhole instrument system while that system is protected from the drilling environment. A protective housing for the downhole instrument system is therefore required. If a waterproof and pressure-proof bulkhead with a conductor is provided, the bulkhead represents a point of probable failure in circumstances of robust handling, and the permanent wired connection is inconvenient in drilling operations if the system is integrated into a drill string. This is shown in figure 2 below:

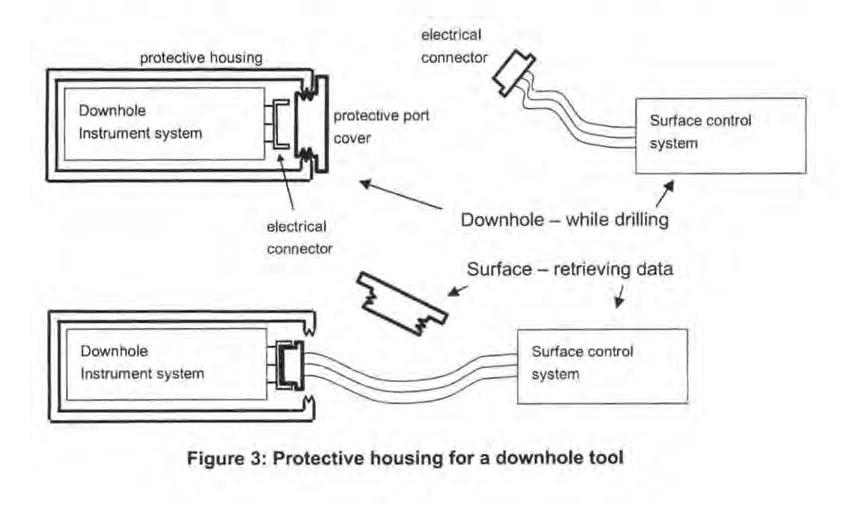

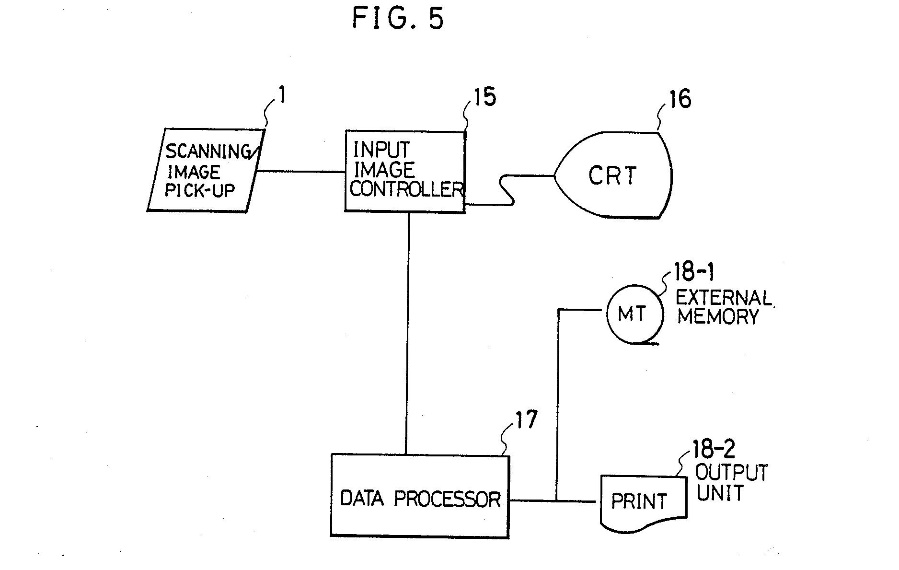

57 Where LWD is not required, but data can be retrieved at the surface at a later time, an option is to disconnect the wires and fully protect the instrument. As shown in figure 3 below, the instrument is fully enclosed in the housing, with a removable port cover that can be opened to expose an electrical connector on the housing.

58 The main drawbacks of the figure 3 design are: (a) when the housing is opened at the surface, the instrument is exposed to dirt and liquid and other physical damage which may be unavoidable in the drilling environment, (b) opening and closing the port, and plugging and unplugging the connector add steps to the drilling workflow that will slow the operation down, and (c) the electrical connector and the port are inevitable points of failure, given that dirt may get into the joint faces of either, and any misalignment in insertion will also cause failure.

59 Abandoning the permanent wired connection makes it possible to use a multi-wire communications system, allowing full duplex (simultaneous bidirectional) data communication. The disadvantages above suggest the use of a wireless communications method is more appropriate for downhole environments. Given that the housing is metal, electromagnetic (radio) transmission from inside to out is not possible (the housing is a so-called Faraday cage, fully shielding the circuit inside from any radio signals produced outside, and vice-versa).

60 The most easy and straightforward communication method is to use optical wireless communication. The most suitable form of optical communication would be infrared radiation. Infrared radiation is a type of optical signal or light wave. Infrared light has good transmission through humid temperatures and many instrument components can transfer or transmit infrared signals. There is no need to use optical (visible) light unless a human is required to see the light (eg, an entry light or a flashing light).

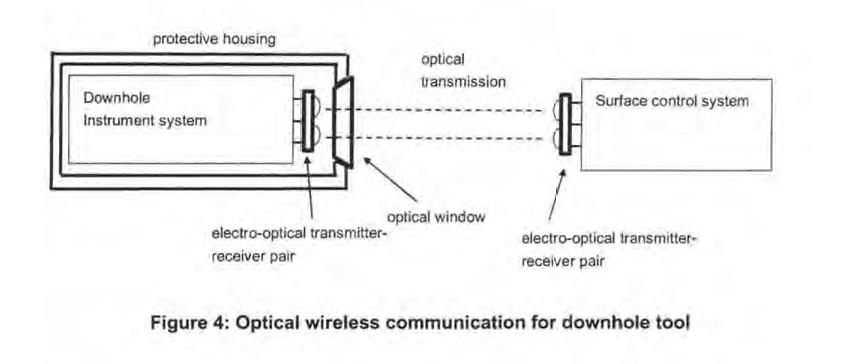

61 The optical wireless communication method is illustrated in figure 4 below. It requires including a transparent window in the protective housing, so that the light signals can be transmitted.

62 This system (in figure 4) is excellent from a workflow point of view because it does not require any fine manipulation of connectors. There are also no connectors to be removed, which would have been a point of vulnerability. The system at figure 4 also allows for very quick transfer of data because all that is required for communication is for the user to bring the downhole instrument system and surface control system into optical alignment. This way, there is very little wait time involved whilst downloading the data from the downhole instrument system.

63 However, any time there is a sealed lid or cap that has to be unscrewed or unfastened, the design introduces a point of vulnerability which means that dirt can be introduced into the seal and there is always a risk that the seal will fail as a result. Professor Tapson’s design in figure 4 is also consistent with the well-established principle that a designer does not want to introduce dirt into sealed instruments. This is especially the case in a drilling environment, where it is always very dirty, and the drilling crew are in a hurry to continue with the drilling operation.

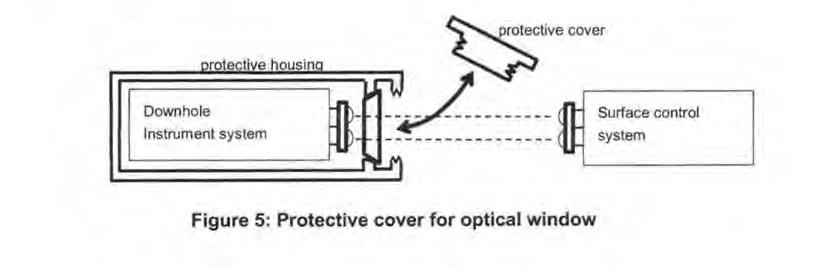

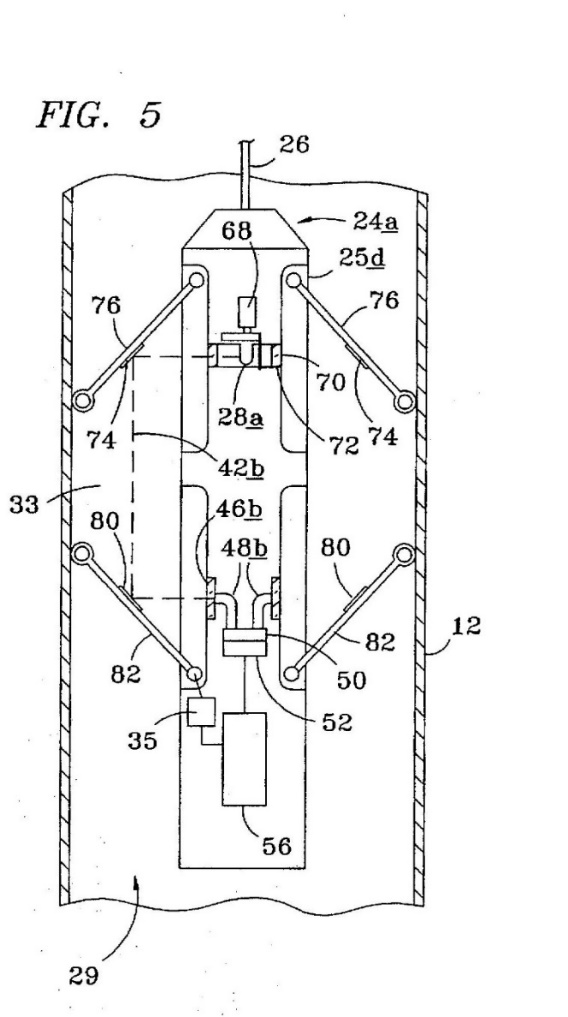

64 Professor Tapson considered that the only remaining point of mechanical failure is that the optical window (which may be waterproof and pressure-proof) is necessarily made from a material such as glass or acrylic plastic, which is not as strong as the metal housing, and susceptible to abrasion and fracture. As a further improvement, it could therefore be covered with a protective metal cover, as indicated in figure 5 below, when communication is not required. The protective metal cover in figure 5 can then be removed manually when communication with the surface control system is required. This protective cover does not need to be water or pressure tight, as it is only protecting the window from mechanical damage.

65 In all of these figures, the downhole tool is shown as a rectangle with the long side being conceptually the axis of drilling, as illustrated in figure 6 below, consistent with using a cylindrical housing which is either integrated into the drill string, or freely lowered into the borehole.

66 Professor Tapson said that while it may make sense for the communication access to be placed at the end of the housing in cases where there is a semi-permanent connection, as in MWD or LWD or post-drilling logging, it does not make sense where the isolated instrument is enclosed within the drill structure. This is because the ends of the cylinder are the easiest (and often, only practical) places to couple the housing to the rest of the system, and also because the ends are likely to receive more mechanical abuse in general handling. It would be preferable not to uncouple or otherwise interfere with the coupling of the housing in order to communicate with the instrument. It would therefore be advantageous to access the instrument through the side wall rather than the ends of the housing. With optical wireless communications, this is easily achieved either by rotating the transmitter-receiver pair through 90 degrees, or simply bending the optical axis 90 degrees by means of a mirror, as shown in figure 7 below. The latter method has the advantage that the basic instrument board does not need to be modified from the above system and can be used in both cases. In typical IRDA-type optical wireless communication, the transmitted optical beam is quite wide, perhaps 20–30 degrees, so some misalignment from the direct optical axis is tolerable.

67 Professor Tapson said that after he provided the above evidence, Reflex’s lawyers asked him to describe in further detail the nature and function of the optical mirror.

68 In response to this request, Professor Tapson said that if the optical signal path is short so that the surface control system is close to the instrument (eg, 10cm or 20cm), a high-quality mirror is not required because there is enough light bouncing around inside the instrument. If the optical signals need to be transmitted over a longer distance (eg, 5m) then a high-quality mirror is required. If a mirror is not available, other reflective surfaces which could be used are polished metal, acrylic, or aluminium foil over plastic. The result from each of these alternatives should not be dramatically different.

69 Although Professor Tapson had the Reflex EZ-TRAC Manual before undertaking his design, he did not read it until after completing his design task. The EZ-TRAC instrument had the following features as at 2009: (a) optical wireless (infrared) communication which was used to communicate and transfer data to and from the downhole instrument (see 8.1.3 of the EZ-TRAC Manual), (b) a handset, “EZ-COM” which had an integrated infrared port on the top of handset for wireless communication with the downhole instrument (see 7.2 and 8.1 of the EZ-TRAC Manual), and (c) the infrared port on the EZ-COM needed to be directed to a corresponding infrared port on the downhole instrument for communication and data transfer (see 8.1.3 of the EZ-TRAC Manual).

70 The EZ-TRAC instrument did not have: (a) a window in the side wall, which Professor Tapson considers to be a rudimentary improvement in his preferred designs over the EZ-TRAC instrument, or (b) a mirror, which as shown in Professor Tapson’s second alternative design at figure 7 he considered is a routine improvement over the EZ-TRAC instrument.

71 Professor Tapson’s understanding of terms used in the patent as at the priority date follows.

72 Azimuth is the angle with respect to magnetic north or geographic north.

73 Backend assembly is a component of the core drill. The backend assembly connects the inner and outer tubes, and incorporates a bearing or other mechanism for restricting relational movement and allows retrieval of the inner tube following breaking off of the bottom, namely, the detachment of the core from the body or parent rock.

74 Bore hole or borehole is any hole drilled into the earth using a drilling machine for the purposes of geological investigation, petrochemical investigation or resource extraction.

75 Core drill refers to the conventional core drilling assembly used in mineral exploration for drilling a core sample, which includes, among other things, a backend assembly, an inner tube, a core lifter, an outer tube and a drilling bit.

76 Core sample, or simply core is a cylindrical core of rock drilled using a core drill from the ground. Geologists can analyse the core sample to determine the composition and other attributes of rock under the ground.

77 Depth is the distance from the surface to a position either along or at the bottom of a borehole.

78 Drill bit or cutting head is an annular, diamond-impregnated cutting tool (known as a “bit”) mounted on the end of a turning string of drill rods that forms part of the outer tube.

79 Inner tube assembly or inner tube, also known as a “core tube”, “sample tube” or “core barrel”, is a tube which sits inside the outer tube and progressively receives the core sample as drilling advances into the rock.

80 Outer tube, also known as the “outer barrel”, is the assembly into which the inner tube fits during core drilling.

81 Professor Tapson then considered the following patents:

(1) US Patent No 4899277 “Bore hole scanner with position detecting device and light polarizers” granted 6 February 1990 (Iizuka);

(2) US Patent No 5729013 “Wellbore infrared detection device and method” granted 17 March 1998 (Bergren); and

(3) US Patent No 7777643 “Optical communications with a bottom hole assembly” granted 17 August 2010 (Sun).

82 The Iizuka patent says that:

This invention relates to a bore hole scanner (an apparatus for observing the wall of a bore hole which, in the present invention, refers to boring holes and pipe holes and the like) for being raised, lowered and moved within a bore hole to observe the wall of the bore hole by means of a scanner incorporated in a sonde.

83 The summary in the Iizuka patent says:

An object of the present invention is to provide a bore hole scanner in which movable portions in the bore hole observing section are eliminated to do away with wearing components and facilitate maintenance.

Another object of the present invention is to provide a bore hole scanner with which a bore hole can be scanned at high speed.

In accordance with the present invention, the foregoing objects are attained by providing a bore hole scanner comprising a light projecting device for projecting a light beam toward the bore hole wall, a conical mirror arranged coaxially with respect to a sonde for condensing light reflected from the bore hole wall, image forming device arranged in front of the conical mirror, photoelectric transducing device for converting a light signal into an electric signal, optical fibers for introducing an image, which is formed on concentric circles by the image forming device, to the photoelectric transducing device, data processing device for scanning and extracting signals from the photoelectric transducing device, and for generating and processing image data indicative of the hole wall surface, and sonde position detecting device for detecting orientation and position of the sonde.

84 Figure 3 in Iizuka is:

85 Professor Tapson said that Iizuka discloses a downhole survey tool and system being a borehole scanner, which uses light to scan or probe the wall of the borehole optically to establish an optical survey of the borehole. Iizuka’s borehole scanner uses a sonde as an optical device whereby light is projected onto a borehole wall using a conical mirror. The sonde detects the light reflected from the borehole using a further conical mirror. This reflected light is condensed using a lens before travelling through optic fibres to a photoelectric transducer whereby the light signals are converted to electric signals corresponding to the intensity of the reflected beam. A data processing unit then detects and processes the electric signals to generate image and positional data indicative of the borehole wall surface. The sonde is raised and lowered in the borehole to produce a continuous image of the borehole wall surface.

86 According to Professor Tapson, the borehole scanner disclosed by Iizuka is not confined to any particular field and is appropriate for use in any borehole as the description of the invention refers extensively to a borehole but does not describe what kind of borehole. There is nothing in the technical description in Iizuka which makes Professor Tapson believe that this invention is limited to work in any kind of borehole.

87 Professor Tapson considered that asserted claim 1 and dependent claims 5, 7, 8, 9, 10, 12 and 17 of the patent are disclosed in Iizuka.

88 The Bergren patent says:

This invention relates to an infrared detection device for determining sources and concentrations of oil and water flow in cased and uncased wellbores; and more particularly to an infrared detection device insertable into a wellbore without interrupting the flowing fluid production; and more particularly to an infrared detection device which is insertable into an inclined or horizontal wellbore casing, to provide a plurality of radially-spaced detection zones across the wellbore cross section, so that two-phase and three-phase fluid flow patterns may be detected and logged along the length of the wellbore casing.

89 The background in the Bergren patent explains that:

Water production from hydrocarbon fluid production wells has been a longstanding problem. Mature oil fields which are being waterflooded to stimulate oil production may experience water flows from production wells which exceed ninety percent (90%) of total fluid production from such wells…

…

Detection of a source or sources of water downhole is considered difficult with existing technology. It is particularly difficult to determine the sources of water in inclined wellbores or in horizontal wellbores…

…

90 The summary of the invention in Bergren is:

An infrared source and detector disposed downhole is provided which is capable of determining whether the fluid flowing past the detector is water or oil. It has been found that the optical densities of water and crude oil with respect to the transmission of infrared radiation are particularly distinct… By a particular arrangement of a downhole logging device having a tool body carrying an infrared radiation source and a detector onboard, longitudinally spaced sections of a perforated wellbore casing can be identified which are producing excessive amounts of water. Particular areas, zones or radial locations about the wellbore radius within a given longitudinal section which are the source of excess water production can also be identified. Based upon a plurality of discrete infrared detection zones around the tool body, the flow pattern or flow regime of production fluid flow can be determined without interrupting production to take samples.

Advantages of the device described and shown in the diagrams are that the device may be traversed through the well without interrupting fluid production during the analysis procedure. The device is capable of analyzing all fluid flow on an average or selective basis at any longitudinal location along the wellbore and the device may be continuously traversed through the wellbore to minimize analysis time and to accurately locate sources of excessive water into the well and/or desirable quantities of oil production into a well.

91 Figure 2 in Bergren is:

92 Professor Tapson said that Bergren discloses a downhole survey tool and system, being an infrared detection device or a logging device composed of an infrared source, transmitter and detector that is inserted into a borehole to optically survey the borehole and determine the source and concentration of oil and water flow. The Bergren infrared detection device uses an infrared transmitter as an optical device to transfer infrared radiation from an infrared source through production fluid flowing in a borehole. The infrared transmitter uses infrared signals travelling through optical fibres bent at a 45 degree angle to redirect infrared signals into the flowing production fluid. Infrared signals flowing through the production fluid are subsequently detected by mirrors located on the infrared receptors located around the infrared transmitter. Once the infrared signals are detected, the infrared detector logs and analyses the data in order to determine whether the fluid flowing past the infrared detector is water or oil. As such, this infrared detection device is able to provide information regarding the geology of the borehole.

93 The Bergren infrared detection device is an oil and gas instrument as it is intended for determining the concentration of hydrocarbon fluids and describes how transmitted light can be used to establish such concentrations. Nonetheless, Professor Tapson still considered the Bergren infrared detection device to be a device which transferred infrared signals to and from downhole equipment, particularly as the asserted claims of the patent are not limited in their application or to any field.

94 Professor Tapson considered that asserted claim 1 and dependent claims 5, 7, 8, 10, 12 and 17 of the patent are disclosed in Bergren.

95 The Sun patent says in its background section that:

Monitoring of various parameters and conditions downhole during drilling operations is important in locating and retrieving hydrocarbons, such as oil and gas, there from. Such monitoring of the parameters and conditions downhole is commonly defined as “logging”.

96 Sun explains:

Typically, such data may initially be stored in various components downhole. The data is then downloaded from these components to a computing device on the surface for analysis and possible modifications to the current drilling operations. A current approach for downloading and downloading of this data includes the use of low data rate electrical connections after the downhole drilling tools are pulled out of the borehole.

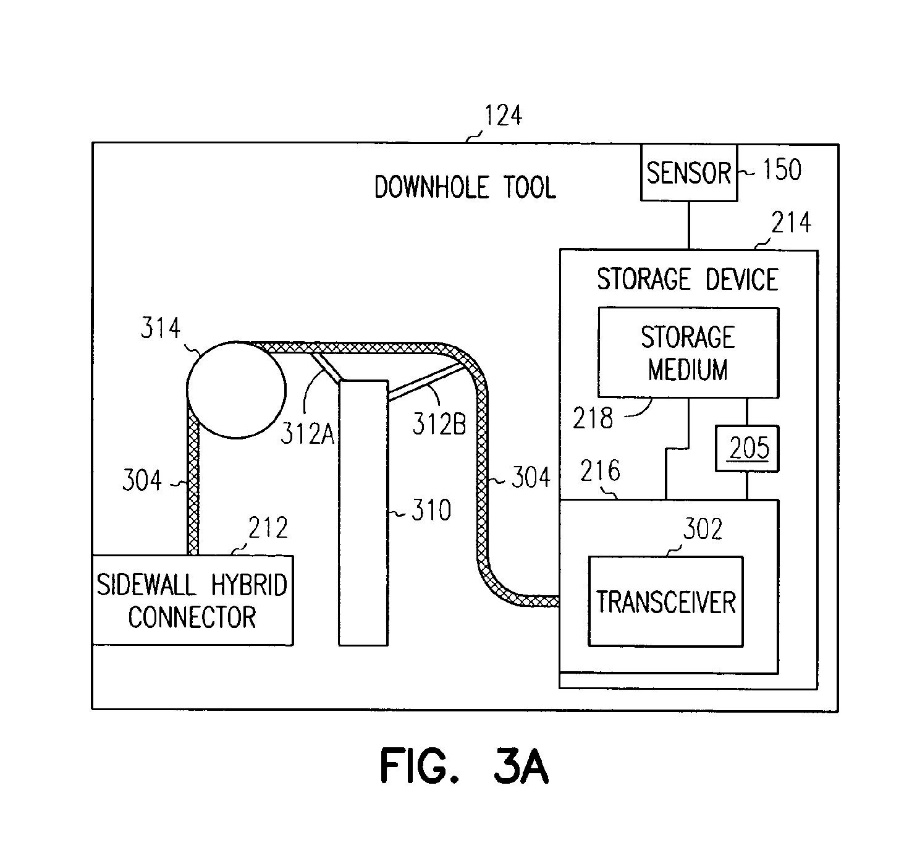

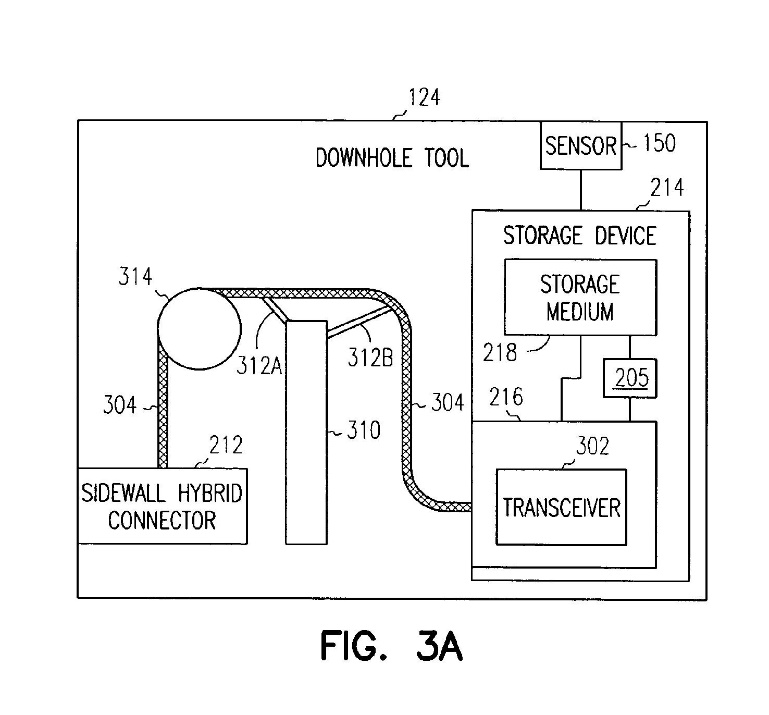

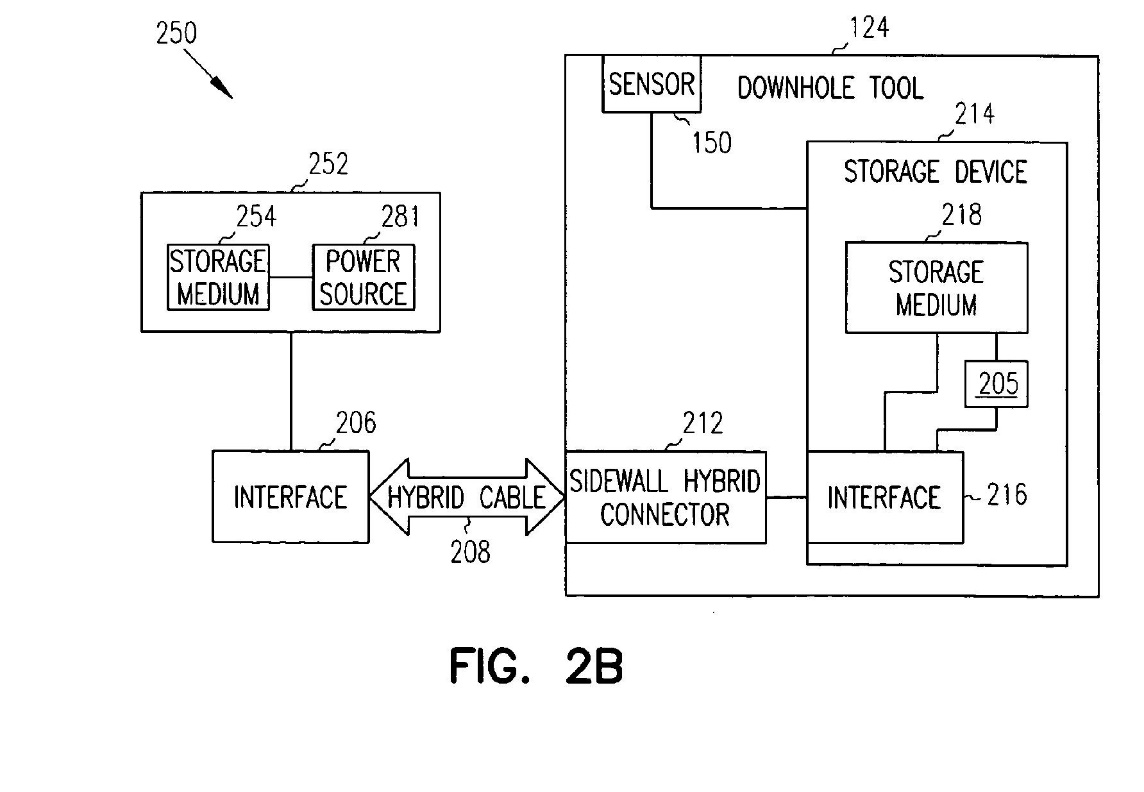

97 The detailed description of the invention in Sun includes figure 3A as follows:

98 Professor Tapson said Sun describes a system for drilling operations consisting of a downhole tool with an optical communications device, computing device or portable handset with storage, interface, hybrid cable and a power source. While Sun’s optical communications device is related to the field of oil and gas, Professor Tapson considered that the Sun optical communications device is capable of equal application and use in mining, where maintaining the physical integrity of downhole electronics and seals is still a problem. In particular, Sun discloses an optical communications device whereby borehole data obtained from sensors in the downhole tool can be transmitted to a computing device or portable handset located on the surface. Sun envisages communicating with the downhole tool when it is at or near the surface to a computing device or portable handset. Sun discloses that optical data communication and transmission of data between the downhole tool and the computing or hand-held device located at the surface occurs via a hybrid cable. A hybrid cable is a form of wireless communication. The reason for this is that, where the hybrid cable uses an optical fibre for optical data communication external to the downhole tool this is not a wired connection, but a form of “wireless communication”. Wireless communication in the context of the patent means, as Professor Tapson understood it, that the electromagnetic transfer of information between two or more points are not connected by an electrical conductor.

99 According to Professor Tapson, Sun’s optical communications device is therefore highly similar to the claimed invention in the patent as it:

(1) focuses on solving the same problem as the patent, namely, communicating with the downhole tool whilst maintaining the physical integrity of downhole electronics, eg, maintaining the integrity of the seals in the body of the downhole tool and still being able to communicate with the surface unit;

(2) transfers borehole data in the form of electromagnetic signals to and from downhole equipment to an external computing device or portable handset located at the surface using wireless communication;

(3) envisages the use of optical communication in a downhole tool, and/or as part of a system for drilling operations; and

(4) comprises of the same components and equipment as the patent, including:

(a) using optical fibres together with routing fixtures and a spindle to change the direction of optical signals travelling within so they can be emitted through an aperture by the sidewall hybrid connector and continue optical communications external to the downhole tool to the surface; and

(b) a portable handset with memory instead of a computing device to communicate with the optical communications device downhole and/or analyse the borehole data at the surface.

100 Accordingly, Professor Tapson considered that the invention claimed in the patent is anticipated by the Sun optical communications device. He considered that asserted claim 1 and dependent claims 5, 7, 8, 10, 12, 17, 21, 22, 24, 25, 27 and 29 of the patent are disclosed in Sun.

101 Professor Tapson considered the issue of inventive step having reviewed the three prior art documents, Iizuka, Bergren and Sun on two bases: (a) in light of the common general knowledge alone, and (b) in light of the common general knowledge together with the information disclosed in each of the prior art documents.

102 As to the common general knowledge alone, Professor Tapson considered his design exercise demonstrated that the invention in the patent would have been obvious at the priority date. Asserted claims 1, 5, 7, 8, 9, 10, 12, 17, 21, 22, 24, 25, 26, 27 and 29 of the patent are disclosed in Professor Tapson’s design exercise. According to Professor Tapson, claim 28 is not disclosed but is obvious. Claim 28 claims “the device including a recessed end portion including an internally projecting conical, domed, facetted and/or tapered end surface of the body”. Professor Tapson said that anyone who has worked with optics would know how a “front-surface” or “rear-surface” mirror works and/or can be created. Front-surface mirrors create less distortion of the image because the light is reflected directly, whereas in a rear-surface mirror some of the light reflects off the first surface of the mirror substrate when the light path enters it; some optical distortion takes place in the mirror substrate; and some light is reflected off the substrate surface as the light path exits it.

4.1.9 Professor Tapson’s response to Professor Dupuis

103 Professor Dupuis’ evidence is discussed below.

104 In response to Professor Dupuis’ evidence, Professor Tapson disagreed that “downhole equipment” in the context of the patent is limited to equipment used by a driller to gather data during drilling operations.

105 Professor Tapson disagreed that the term “borehole” is not used in the field of oil and gas. In the field of oil and gas, a hole is generally called a borehole during the exploration phase and becomes a well once it is producing.

106 Professor Tapson disagreed that the optical device in the patent must be a singular object and not a structure or a system, as the patent says the optical device may be formed of one or multiple parts.

107 Professor Tapson disagreed that air or gas like air cannot be part of the body of the optical device as air and gas are optical media of different refractive index than solids or liquids, but can be used to create directional change via refraction and reflection in the same way as solid or liquid media and an optical device can include air or gas like air as part of the optical (light) path.

108 Professor Tapson disagreed that optical fibres do not alter the direction of light since its direction of propagation remains in the axial direction of the optical core of the fibre. Optical fibres are generally constructed by drawing or extruding a fibre from glass or plastic. They are constructed to comprise a core material and a cladding material, where the core usually has a higher refractive index than the cladding. Light which is propagating from a high refractive index material to one of low refractive index will usually reflect, if it meets the interface at a low angle.

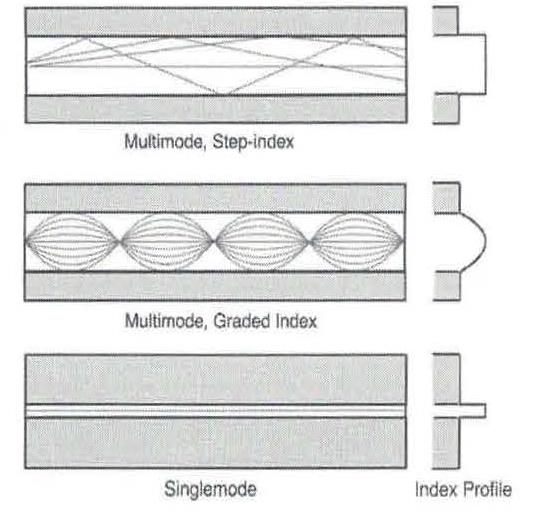

109 Professor Tapson explained that there are broadly two categories of optical fibres, being single mode and multimode optical fibres. Within these categories, optical fibres may be subcategorised by the composition of their core. The below figures, extracted from the optical fibre page from the Fiber Optic Association, Inc, Reference Guide to Fiber Optics (available at the following link: https://www.thefoa.org/tech/ref/basic/fiber.html), illustrate a multimode fibre, graded-index multimode fibre and a single mode fibre, with their associated refractive index profiles shown on the right. The paths of typical light rays propagating through the fibres are shown in the interior of the fibres.

110 Single mode optical fibres are a special type of optical fibre that are so narrow only a single wave of light can travel through them. That single wave cannot bounce from one core-cladding “wall” to the other, and instead must propagate down the middle of the fibre. They are generally only used for telecommunication and a few, very specialised, other applications (eg, fibreoptical gyroscopes).

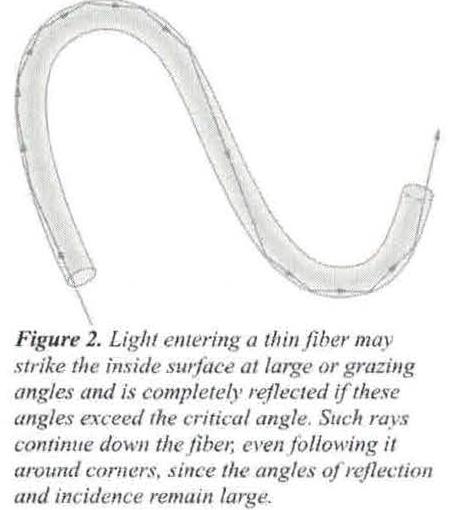

111 In contrast, multimode optical fibres are wider and allow several waves of light to propagate simultaneously. These light waves travel through the fibre by way of “total internal reflection”. The structure of these optical fibres creates a reflective interface between the core and the cladding, so that when light is injected into the core from one end of the fibre, it reflects off the internal interface. The light therefore propagates down the length of the fibre and emerges at the other end. The figure below, extracted from section 10.4: “Total Internal Reflection” in the Douglas College Physics 1207 Winter 2020 custom textbook adapted from Open Stax College Physics by the Department of Physics and Astronomy at Douglas College (Douglas College Physics), illustrates light propagating through a thin (multimode) optical fibre, including around corners:

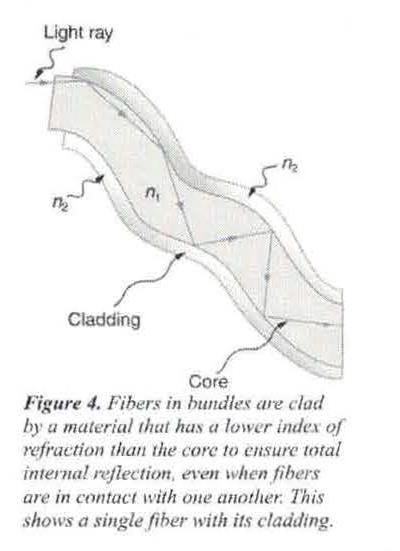

112 Total internal reflection is illustrated in the figure below, extracted from the same Douglas College Physics source:

113 Professor Tapson said that, as can be seen from the above, by means of total internal reflection, light propagating through the (multimode) fibre core reflects off the core-to-cladding interface, and in this way is confined inside the fibre. The light waves bounce from wall to wall inside the fibre and thus propagate down its length and can change direction if the walls of the fibre are bent to change the angle of reflection. The action is no different than if the fibre was a hollow cylinder with a reflective mirror inner surface. By this means, light signals can be communicated over distances and around bends and underwater and underground, in ways that would not be possible if the light beam had to be shone directly through a homogenous optical medium such as air or water.

114 Professor Tapson said that, generally, when optical fibres are used in or with downhole equipment, multimode fibres are used, unless the unique properties of single-mode fibres are specifically required. Multimode fibres are generally more robust, being made of plastic rather than glass. Multimode fibres are more easily cut, joined and repaired. Multimode fibres have large core diameters (typically 0.5–1mm) and large acceptance angles (typically up to 15 degrees off-axis) which makes it easy to launch light into the core. Single mode fibres have extremely narrow cores, typically 5–10um (micrometres) or a hundred times smaller than a multimode fibre, and the acceptance angles are extremely small (typically less than 1 degree), so it requires specialized interface optics and laser sources to launch a signal into a single mode fibre.

115 Accordingly, at the priority date Professor Tapson understood that: (a) optical fibres do alter the direction of light, (b) the direction of the propagation of light in the fibre is not the same as the “axial direction of the optical core of the fibre”, and (c) optical fibres are a “signal direction altering means” within the meaning of the patent. Professor Tapson said that this is also supported by the following in the patent:

(1) [0034] of the patent says “…Alternatively the light path may be provided by a light transmitting conduit within the body”. This indicates to Professor Tapson that the patent contemplates the use of optical fibres or light-pipes, being a kind of rudimentary optical fibre used when a light beam must be redirected over a short-range or in a tight space;

(2) claim 6 relates to the device of any preceding claim, “wherein the electromagnetic signal direction altering means includes a boundary at a change of material or edge of a portion of the device”. This indicates to Professor Tapson that the signal direction alteration should be by means of reflection or refraction, as these are optical effects that occur at a change of material; and

(3) claim 7 relates to the device of any preceding claim, “including a reflector to reflect at least a portion of the electromagnetic signal”, which makes it clear to Professor Tapson that reflection at an interface (like in an optical fibre) is an embodiment within the scope of the patent.

116 Professor Tapson also said that even if light did propagate along the core of a fibre (which might happen in a single mode optical fibre) if the fibre was bent: (a) the axial direction of the core at one end of the fibre would not be the axial direction of the core at the other end of the fibre, (b) light entering the fibre along the optical axis at one end, would exit in the different direction in which the optical axis was projecting at the other end, (c) the optical device would therefore still alter the direction of the light, and (d) the optical device would be a “signal direction altering means” within the meaning of the patent.

117 Professor Tapson disagreed that the entirety of the system must be downhole. He said that there is nothing in the patent that restricts the data gathering system to being down the hole. The adjective “downhole” modifies or describes the data, that is, it is a system for gathering data pertaining to the downhole environment.

118 Professor Tapson disagreed that the electronics unit must consist of one circuit board as there is nothing in the patent that restricts the electronics unit to one circuit board and many electronics units contain multiple circuit boards.

119 In response to Professor Dupuis’ comments on his analysis of the prior art documents, Professor Tapson said the patent is not limited to mineral mining, excluding oil and gas and therefore “downhole equipment” within the meaning of the patent does not exclude equipment used in the oil and gas industry.

120 As to Iizuka, Professor Tapson said:

(1) wireline tools are “downhole equipment” within the meaning of the patent;

(2) the optical device in Iizuka transfers an electromagnetic signal to or from an electronics unit of downhole equipment. The patent does not require restricting or constraining the signal to an application (eg, communication but not sensing);

(3) the optical components do not exclude optical fibres;

(4) the light path in the patent cannot be understood to be constrained to the body of the optical device. The light path in the patent must extend outside the body of the optical device, otherwise the electromagnetic signal would be unable to be transmitted to or received from the external receiver or transmitter. In Iizuka the light path reflects off the conical mirrors in the same fashion as in the patent;

(5) the patent allows for part of the light path within the body, however, the patent does not describe the light path as being formed of a specific type of optical material. It could be air, or liquid, or a transparent solid and the invention claimed in the patent would work (though liquid is less practical). The patent does not state that the body of the optical device is a waveguide, and it is not necessary for the operation of the invention claimed in the patent. Professor Dupuis appears to have restricted the patent to one embodiment in which there is a mirror embedded within a solid optical material (with the added feature of the body being a waveguide, which is not described in the patent);

(6) in claim 1 of the patent, there is no requirement that the electronics unit must receive and send an electromagnetic signal. Rather, claim 1 says that the electromagnetic signal can be transferred to or from the electronics unit and claim 5 says wherein the electromagnetic signals may be incoming to or outgoing from the electronics unit. This is reinforced by [0018] and [0025] of the patent. Accordingly, “associated with” in the context of claim 1 means that the signals communicate in some way with the electronics unit. The signals may be generated by or received by the electronics unit. There is no restriction that the signals originate in or from the electronics unit. Furthermore, the signals may be processed in the electronics unit, or processing may take place prior to or after the electronics unit in the signal processing chain; and

(7) in relation to claim 8 “the reflector including a reflective material applied to, mounted to, or formed on or within the body”, Professor Dupuis has introduced multiple additional features for the invention in Iizuka not mentioned in that patent.

121 As to Bergren, Professor Tapson said:

(1) workovers (maintenance or specialised interventions required for an oil or gas well to be put in service or remain in service for the purpose of producing hydrocarbons) represent “downhole equipment”;

(2) he did not suggest that optical fibres are waveguides; and

(3) insofar as Professor Dupuis asserts that claim 22 of the patent requires the electromagnetic signal direction altering means to redirect signals incoming to the electronics unit, the integer specifically says “and/or” and cannot be limited in this way.

122 As to Sun, Professor Tapson said:

(1) there is no reference to a protective face cap, cover or protective face seal for the sidewall hybrid connector in Sun, and he did not see why one would be required; and