FEDERAL COURT OF AUSTRALIA

SNF (Australia) Pty Limited v BASF Australia Ltd [2019] FCA 425

ORDERS

Appellant | ||

AND: | Respondent | |

AND BETWEEN: | Cross-Appellant | |

AND: | Cross-Respondent | |

DATE OF ORDER: |

THE COURT ORDERS THAT:

1. The appellant’s appeal be dismissed.

2. Australian patent application no. AU 2004203785 (as amended) proceed to grant.

3. The appellant pay the respondent’s costs of and incidental to the appeal.

4. There be a stay on the operation of orders 2 and 3 for 21 days subject to further order.

5. The respondent’s cross-appeal be dismissed with no order as to costs.

6. Any previous orders made under ss 37AF and 37AG of the Federal Court of Australia Act 1976 (Cth) be varied, if necessary, so as to permit publication of the Court’s reasons.

7. Liberty to apply.

Note: Entry of orders is dealt with in Rule 39.32 of the Federal Court Rules 2011.

ORDERS

VID 1318 of 2016 | ||

| ||

BETWEEN: | SNF (AUSTRALIA) PTY LIMITED Appellant | |

AND: | BASF AUSTRALIA LTD Respondent | |

AND BETWEEN: | BASF AUSTRALIA LTD Cross-Appellant | |

AND: | SNF (AUSTRALIA) PTY LIMITED Cross-Respondent | |

JUDGE: | BEACH J |

DATE OF ORDER: | 27 March 2019 |

THE COURT ORDERS THAT:

1. The appellant’s appeal be dismissed.

2. Australian patent application no. AU 2013204568 (as amended) proceed to grant.

3. The appellant pay the respondent’s costs of and incidental to the appeal.

4. There be a stay on the operation of orders 2 and 3 for 21 days subject to further order.

5. The respondent’s cross-appeal be dismissed with no order as to costs.

6. Any previous orders made under ss 37AF and 37AG of the Federal Court of Australia Act 1976 (Cth) be varied, if necessary, so as to permit publication of the Court’s reasons.

7. Liberty to apply.

Note: Entry of orders is dealt with in Rule 39.32 of the Federal Court Rules 2011.

BEACH J:

1 The appellant (SNF) has appealed two decisions of a delegate of the Commissioner of Patents made in respect of Australian patent applications no. AU 2004203785 (the 785 application) and no. AU 2013204568 (the 568 application); I will refer to both as the opposed applications. The appeals have been brought under s 60(4) of the Patents Act 1990 (Cth) (the Act), with each appeal by way of a rehearing de novo.

2 Each of the opposed applications now stands in the name of BASF Australia Limited (BASF), having previously been assigned by Ciba Specialty Chemicals Water Treatments Limited (Ciba) to BASF.

3 Each of the opposed applications seeks the grant of a standard patent for an invention(s) entitled “Treatment of aqueous suspensions”. The opposed applications are derived from an international patent application filed on 7 January 2004 no. PCT/EP2004/000042; this application was published on 22 July 2004 as international publication no. WO/2004/060819 (the PCT application). The opposed applications each claim priority from a UK patent GB 0310419.7 filed on 7 May 2003 (the priority date).

4 The decisions which are the subject of the appeals before me are:

(a) a decision of the delegate Dr Steven Barker made on 16 February 2016 (the 785 decision); see SNF (Australia) Pty Ltd v Ciba Specialty Chemicals Water Treatments Limited [2016] APO 8; and

(b) a decision of that delegate made on 18 October 2016 (the 568 decision); see SNF (Australia) Pty Ltd v Ciba Specialty Chemicals Water Treatments Limited [2016] APO 72.

5 The opposed applications are governed by the provisions of the Act as they stood before the “Raising the Bar” amendments (Intellectual Property Laws Amendment (Raising the Bar) Act 2012 (Cth)). Accordingly, the pre-amendment versions of provisions such as s 7 concerning novelty and inventive step continue to apply.

6 In the 785 decision, the delegate:

(a) decided that the invention defined in each of claims (as accepted) 1 to 11, 14, 16, 17, 19, 21 to 27, 29 and 30 of the 785 application lacked an inventive step solely in light of international publication no. WO 01/92167 (the Gallagher patent) filed by Ciba and the inventors for which were inter-alia Mr Michael Gallagher and Mr Stephen Adkins, and were therefore invalid;

(b) decided that the invention defined in each of claims (as accepted) 12, 13, 15, 18, 20 and 28 of the 785 application had not been shown to lack an inventive step and were not invalid; and

(c) allowed the patent applicant a period of 60 days within which to propose amendments to the 785 application, indicating that the deficiency in relation to claims 1 to 11, 14, 16, 17, 19, 21 to 27, 29 and 30 could be overcome by amendment to include a co-disposal integer.

7 Pursuant to s 105(1A) of the Act and under orders made by me on 21 July 2016, the claims of the 785 application were so amended. The effect of the amendment was to limit the scope of all of the amended claims to a co-disposal process by including the requirement that the “process comprises co-disposal of coarse and fine solids as a homogenous mixture”. That amendment was sufficient to address the delegate’s concerns.

8 In the 568 decision, the delegate:

(a) decided that the invention defined in claims 2 and 3 (as accepted) and the claims appended to claims 2 and 3 lacked an inventive step in light of the Gallagher patent;

(b) decided that the invention defined in claim 1 (as accepted) had not been shown to lack an inventive step; and

(c) allowed the patent applicant a period of 60 days within which to propose amendments to the 568 application to overcome the deficiency in relation to claims 2 and 3 concerning the Gallagher patent.

9 Again, pursuant to s 105(1A) of the Act and under the orders made by me on 21 December 2016, the claims of the 568 application were amended. The effect of the amendment was to limit the scope of all of the amended claims to a co-disposal process by making a similar amendment as for the 785 application.

10 As noted, the opposed applications are derived from the PCT application filed on 7 January 2004. Ciba had previously also divided out five innovation patents from the PCT application, which were the subject of proceedings before Kenny J discussed below. It had also divided out various standard patent applications from the PCT application. Two of those applications are the opposed applications which are the subject of the present appeals. Another application (AU 2012216282) has been the subject of an opposition proceeding in which a decision was handed down by the delegate on 18 April 2018. SNF has filed a notice of appeal in respect of that decision which appeal I am also presently case managing. There have also been other applications for standard patents derived from the PCT application that have been withdrawn, lapsed or refused; there is yet a further application awaiting examination. For present purposes I need say nothing more about them.

11 As I have said, the parties were involved in Federal Court proceedings which concerned, inter-alia, the validity of five innovation patents which were filed as divisional applications of the 785 application.

12 In 2008, SNF commenced revocation proceedings in Federal Court proceedings number VID 447 of 2008 (the 2008 proceedings) concerning the validity of innovation patents nos. 2006100744, 2006100944, 2007100377, 2007100834 and 2008100396 (the innovation patents). Ciba cross-claimed for infringement.

13 The innovation patents were held to be valid by Kenny J and Ciba succeeded in its cross-claim for infringement (SNF (Australia) Pty Ltd v Ciba Speciality Chemicals Water Treatments Ltd (2011) 92 IPR 46).

14 SNF appealed that decision to the Full Federal Court, where a majority dismissed the appeal (SNF (Australia) Pty Ltd v Ciba Speciality Chemicals Water Treatments Ltd (2012) 204 FCR 325). SNF then sought special leave to appeal, which leave was refused.

15 Subsequently, in April 2014 SNF filed an interlocutory application seeking to re-open the 2008 proceedings and her Honour’s judgment therein. That application was dismissed (SNF (Australia) Pty Ltd v Ciba Specialty Chemicals Water Treatments Limited (2015) 114 IPR 231). SNF then sought leave to appeal that decision, but the Full Federal Court refused such leave (SNF (Australia) Pty Ltd v Ciba Speciality Chemicals Water Treatments Ltd [2016] FCAFC 88).

16 Further, in November 2011 a related entity of SNF, SNF Inc., commenced proceedings against Ciba in the Canadian Federal Court seeking a declaration that a patent related to the opposed applications (the Canadian patent), which claimed essentially the same process as the opposed applications, was invalid. The Canadian patent was also derived from the PCT application. On 24 August 2015, Phelan J determined that the Canadian patent was invalid (SNF Inc. v Ciba Specialty Chemicals Water Treatments Limited (2015) 133 CPR (4th) 259; [2015] FC 997).

17 I would note at this point that many of the witnesses who gave evidence before me on these appeals have previously given evidence in these other proceedings. Moreover, some aspects of Kenny J’s reasoning discusses issues that I am also concerned with. Nevertheless, I must deal with the issues on the evidence before me. Further, some of Kenny J’s analysis must be understood in light of the fact that she was dealing with innovation patents whereas I am concerned with applications for standard patents.

18 In general, SNF contends before me that:

(a) the invention so far as claimed in any claim of the opposed applications does not involve an inventive step;

(b) the invention so far as claimed in any claim of the opposed applications was secretly used in the patent area before the priority date of that claim by or on behalf of or with the authority of the patent applicant or nominated person or the patent applicant’s or nominated person’s predecessor in title to the invention; and

(c) all of the claims of the opposed applications are not novel except for:

(i) claims 5, 18, 21 and 23 for the 785 application; and

(ii) claims 15, 27 and 30 of the 568 application.

19 BASF has cross-appealed those parts of the 785 decision and 568 decision in which the delegate held that certain claims of the 785 application being claims 1 to 11, 14, 16, 17, 19, 21 to 27, 29 and 30 and certain claims of the 568 application being claims 2 and 3 and the appended claims lacked an inventive step in light of the Gallagher patent. That was the only ground upon which the delegate held any claims of the opposed applications to be invalid. But notwithstanding its cross-appeal, BASF has amended the claims of the 785 application and the 568 application to overcome the findings of the delegate by narrowing the relevant claims of the opposed applications to include a “co-disposal” integer. In the 785 decision the delegate concluded that “it has not been shown that the claims relating to co-disposal lack inventive step” (at [325]). In the 568 decision the delegate held that claim 1 of the 568 application features the “significant new step” of co-disposal (at [21]), held that the Gallagher patent suggested “a preference for disposal of tailings that are substantially composed of fine particles” (at [39]), and said that “I am satisfied that the evidence shows that it was known to combine fine and coarse particles. However, the evidence does not show that it would have been a matter of routine to do this in the context of the problem” (at [56]). Given the amendments ordered by me and my decision on SNF’s appeals, it is not necessary to say anything further on BASF’s cross appeals.

20 BASF also contends by its notices of contention that the delegate erred in finding that the person skilled in the art could as at the priority date have been reasonably expected to have ascertained the relevant prior art relied on by SNF. I will deal with this later when I discuss the s 7(3) question.

21 Now SNF bears the onus in relation to establishing each ground of opposition and corresponding ground of appeal before me. The authorities establish that for the opposition to be upheld it must be clear that the patent, if granted, would not be valid (Meat & Livestock Australia Limited v Cargill, Inc (2018) 354 ALR 95; (2018) 129 IPR 278; [2018] FCA 51 at [11] (MLA (No 1))).

22 Further, in MLA (No 1) at [11], I agreed with the views expressed by Bennett J in Austal Ships Pty Ltd v Stena Rederi Aktiebolag (2005) 66 IPR 420 (Austal Ships), that where there are conflicting sets of expert opinions on a principal question such as lack of inventive step, unless one set of views can be rejected on proper grounds, the opponent will not have discharged its legal burden to the requisite degree. But the higher standard of satisfaction does not apply to findings of underlying primary facts. As Bennett J explained in Austal Ships at [12]:

I can accept that a lower standard may apply to proof of evidence such as whether a document has been published or, indeed, whether a prior art vessel was well-known. I do not accept that it properly applies to the factual question that itself is the test for obviousness or lack of inventive step. Where the factual question is itself the legal test, as set out in s 7(3) of the Act, it seems to me that it should be determined at the higher standard. That means that where there are two opposing expert views that are conclusive on obviousness, both presented bona fide by witnesses of accepted expertise, unless one set of views can be rejected on proper grounds, the legal burden to establish a ground of opposition is not discharged; the court cannot be practically certain that obviousness or lack of inventive step is established.

23 Further, in Aspirating IP Ltd v Vision Systems Ltd (2010) 88 IPR 52, Besanko J cited the above passage in Austal Ships and said at [35] that:

The primary facts are to be established on the balance of probabilities, but the ultimate facts – the facts leading directly to a conclusion of a lack of novelty or a conclusion of obviousness – must be proved to the level of practical certainty.

24 Now there has been limited judicial consideration of particular matters which must be proved to a level of being “clear” as opposed to those that can be established on the balance of probabilities. But decisions of various delegates of the Commissioner of Patents provide some guidance on where the division between the two standards has been drawn in practice.

25 For example, delegates have found that the lower standard of proof is applicable as to whether a matter formed part of the common general knowledge, whether a document has been published and whether in the context of secret use an invalidating sale occurred before the priority date. Contrastingly, delegates have found that the higher standard of proof is applicable as to whether a person skilled in the art would achieve the same results as the invention so far as claimed using slightly different techniques and altered conditions, whether the claims of the invention so far as claimed lack utility and whether the claims of the invention lack novelty.

26 In my view, the following matters are required to be established by SNF at the lower standard of on the balance of probabilities:

(a) the materials routinely referred to by a person skilled in the art;

(b) whether various matters formed part of the common general knowledge at the priority date and what about them and their use was common general knowledge at the priority date including, in the present context, the use of co-disposal processes, the use of belt presses and centrifuges, the use of processes involving the addition of flocculant to thickener underflow in the outlet pipe from the thickener (secondary dosing), the use of flocculants in treating tailings, and the variables routinely adjusted in their use, whether a treatment process which worked effectively on one mineral type would also work effectively on other mineral types, and the use of processes involving the deposition of thickener underflow onto a slope, wall or floor in order to allow tailings to become beached and water to flow out to a lower point for re-use (tailings beaching); I note that it is not now asserted that the use of secondary dosing in tailings beaching (SDITB) was part of common general knowledge at the priority date;

(c) whether relevant prior art being the Backer & Busch papers, the Condolios patent, the Gallagher patent and the Pearson patent (I will precisely identify these later) would have been ascertained, understood and regarded as relevant by a person skilled in the art at the priority date, although there is an argument for saying that the higher standard should apply;

(d) what is disclosed in the Backer & Busch papers, the Condolios patent, the Gallagher patent and the Pearson patent, although there is an argument for saying that the higher standard should apply;

(e) what use was made of the claimed invention by Ciba at Yarraman, Sandalwood and Ardlethan (I will identify these locations later) before the priority date and what was the nature of that use; and

(f) whether the Cable Sands documents (I will describe these later) would have been treated by a person skilled in the art as a single source of information, although there is an argument for saying that the higher standard should apply.

27 On questions of construction, I am also prepared to apply and have applied the lower standard albeit that there is some force in BASF’s submissions that the higher standard should apply.

28 But in my view the following matters are required to be established to the higher standard:

(a) whether any of the claims of the opposed applications were obvious in light of common general knowledge alone;

(b) whether any of the claims of the opposed applications were obvious in light of common general knowledge combined with any of the prior art relied on by SNF;

(c) whether the claimed invention was secretly used by Ciba prior to the priority date; and

(d) whether any of the claims of the opposed applications lacked novelty in light of the disclosures in the Cable Sands documents.

29 In summary and for the reasons that follow, I have determined to dismiss each of SNF’s appeals.

30 For convenience, I have divided my reasons into the following sections:

(a) Technical background ([32] to [141]);

(b) The opposed applications ([142] to [220]);

(c) The witnesses ([221] to [261]);

(d) The person skilled in the art ([262] to [279]);

(e) Construction of the claims ([280] to [372]);

(f) Common general knowledge ([373] to [501]);

(g) Obviousness – legal principles ([502] to [536]);

(h) Obviousness in light of common general knowledge alone ([537] to [1080]);

(i) Common general knowledge plus s 7(3) documents ([1081] to [1410]);

(j) Secret use ([1411] to [1720]);

(k) Lack of novelty ([1721] to [1782]); and

(l) Conclusion ([1783] to [1784]).

31 In these reasons, in terms of the respondent to the appeals I will generally refer to BASF, save for when I need to refer to Ciba directly in discussing contemporaneous conduct and dealings before the priority date.

TECHNICAL BACKGROUND

32 For the most part, the following matters that I have described in this section were common general knowledge as at the priority date and do not appear to be in dispute. It is useful to set these out in order to appreciate the later discussion of the relevant technical issues. In part, I have drawn upon the helpful discussion of some of these matters given by Dr Ross de Kretser, an expert witness called by SNF. Before getting into the detail, let me set out a mini glossary.

33 Terms or expressions used in the relevant field include the following:

(a) “beach angle” refers to the slope or angle of a deposit (relative to underlying material) which forms a stack or heaped geometry;

(b) “beneficiation” is a process of concentrating the value(s) in an ore by separation from waste material;

(c) “bimodal distribution of particle sizes” means there are two distinct sizes of particles within the solid material. Often these are referred to as “fines” and “coarse” fractions;

(d) “co-disposal” means, in simple terms, the disposal of a combination of both coarse and fine tailings particles. In some cases this will involve a clearly bi-modal size distribution which has both coarse and fine particles;

(e) “flocculants” are high molecular weight polymers that induce aggregation of solid particles. This occurs by individual flocculant molecules co-adsorbing on two or more solid particles and binding them together. Due to the increase in their size, the bound solids (often called “aggregates”, “floccules” or “flocs”) have a faster settling rate, but a much lower density, than the individual solids particles;

(f) “intrinsic viscosity” is a measure of the capability of a polymer in solution to enhance the viscosity of the solution. It is related to the volume per unit mass occupied by flocculant molecules in solution and is measured in the unit “dL/g”, which is decilitres per gram;

(g) “rheology” is the study of deformation and flow of fluid matter;

(h) “spirals” are equipment used in mineral processing industry to beneficiate an ore by means of the forces imposed on particles as they flow under gravity in a spiralling motion;

(i) a “stack” or a “heaped geometry” is a deposit of material which is characterised by being larger at the bottom than at the top;

(j) “tailings” are the end product of a mineral processing operation. Tailings are what remain of an ore after the value(s) (e.g. alumina, coal, copper, diamond, gold, nickel, uranium, zinc) have been extracted during the processing operation; and

(k) “yield stress” means, in simple terms, a measure of the minimum force required to be applied to an object to make it deform (i.e. begin to behave as a fluid).

34 Mineral processing is the processing of mined materials to separate the valuable component of the ore such as alumina, coal, copper, diamond, gold, nickel, uranium, zinc from the waste material i.e. the tailings. Such processing usually produces tailings that have the following characteristics:

(a) First, they are in slurry form, comprising process water and particulate matter.

(b) Second, the particulate matter is comprised of large amounts of quartz/silica, various types of clays, and other minerals depending on the host rock for the ore.

(c) Third, the particle size of the particulate matter depends on the level of grinding required for mineral extraction which in many cases is related to the type of mineral and nature of the deposit.

(d) Fourth, in many operations, multiple tailings streams are generated with different characteristic particle size distributions. For example, in mineral sands processing, slimes (fine) and sand (coarse) streams are generated from different parts of the processing circuit. Sand streams are also generated in alumina refining in addition to the fine red mud tailings. In coal processing a coarse reject stream is commonly generated in addition to the fine tailings.

35 Tailings slurries vary in their consistency from having a low solids concentration, and accordingly, being very liquid, to having a higher solids concentration and being more viscous. The solids in the tailings may consist of fine particles, coarse particles or a mixture of both. The fine particles are often referred to as “clay” or “fines”, and the coarse particles are often referred to as “sand”.

36 The particle size of the particulate matter strongly depends on the level of grinding required for mineral extraction which in many cases is related to the type of mineral and nature of the deposit. For example, typical tailings particle sizes can be as follows:

(a) lead zinc: top size 80 to 500 microns, 80% passing 30 to 150 microns;

(b) gold-silver-platinum: top size 80 to 500 microns, 80% passing 30 to 150 microns;

(c) coal: top size 100 to 1500 microns; 80% passing 10 to 900 microns;

(d) bauxite (red mud): top size 100 microns, 80% passing 5 to 10 microns;

(e) mineral sands – slimes: top size 75 microns, 80% passing 10 to 50 microns; and

(f) mineral sands – sand: top size 1000 microns.

37 Mineral tailings typically have a range of particle sizes, generally within the range of 0.5-400 microns, depending on the ore mineralogy and processing regime.

38 Coal, mineral sands, copper, gold, lead, zinc, red mud, silver, uranium and platinum tailings often comprise a mixture of coarse and fine particles. Phosphate and uranium tailings usually only comprise fine particles.

39 Tailings with a bimodal distribution of particle sizes were common at the priority date. The bimodal size distribution of tailings could arise due to either the nature of the treatment process and the mineral being mined, or by deliberate addition of coarser material to a finer tailings stream. Tailings with a bimodal distribution of coarse and fine particle sizes is typical in the mineral sands industry. In contrast, in other industries such as coal tailings, the size distribution is more gradual across a scale of sizes between coarse and fine particles.

40 Let me now address the question of thickeners. A thickener is essentially a large tank which is continuously fed with tailings slurry, typically through a central feeding arrangement called a feedwell, and which has sufficient volume to allow solid particles to settle to the bottom of the thickener and produce a clear overflow of suspending fluid. That overflow is typically recycled to the plant for re-use, or in some cases may contain the valuable product which is processed elsewhere in the plant.

41 The settled tailings or what is referred to as “thickener underflow” are then pumped at relatively low solids concentrations to the deposition area in pipelines or less commonly in open launders or channels.

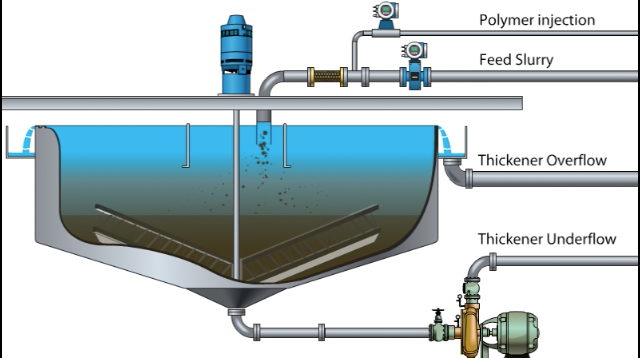

42 A schematic of a thickener, illustrating key features is set out below:

43 As at the priority date, two of the types of thickeners being used were conventional thickeners and paste thickeners. Conventional and paste thickeners are similar pieces of equipment that are designed and operated to produce underflows of different consistencies. The aim of paste thickeners is to increase water recovery and produce a denser underflow compared to conventional thickeners. Paste thickeners are typically used in relation to alumina tailings which contain caustic soda. However, the underflow from both thickeners is generally transported to a deposition area via a tailings pipeline or launder.

44 Thickener underflow is typically disposed of by pumping the underflow through a conduit to a disposal area where the material is allowed to stand, with a view to land reclamation and water recycling. Typically thickener underflow has a solids concentration of between 15% to 80% by weight, being the percentage of solids in the tailings, the rest being water.

45 Let me now turn to discuss flocculants. Water soluble flocculants are used to increase the yield stress of tailings thereby thickening the tailings in order to improve the dewatering and disposal of tailings, irrespective of the mineral type.

46 Flocculants cause tailings to aggregate into flocs which on deposition under certain conditions start to stick together to form a structure that is permeable and allows for further dewatering. With dewatering, the yield stress of the material increases. The addition of the flocculants co-immobilizes the coarse and fine particles in the tailings on deposition. Typically, the higher the flocculant dose, the greater the flocculation of the tailings.

47 Commercially available flocculants including polyacrylamide which are commonly used in the treatment of tailings are either positively charged (cationic), negatively charged (anionic) or uncharged (non-ionic). The choice of charge of the flocculant is governed by the qualities of the tailings to be treated.

48 Flocculant manufacturers make flocculants with different molecular weights which react differently depending on the characteristics of the tailings. The higher the molecular weight, the longer the flocculant chain. The molecular weight of a flocculant is related to its intrinsic viscosity. The higher the molecular weight of the flocculant, the higher its intrinsic viscosity. Almost all commercially available flocculants have an intrinsic viscosity of greater than 5dl/G.

49 Flocculants with a high molecular weight are more effective for “bridging” or “connecting” the particles in the tailings as part of the flocculation process. Flocculants with a higher molecular weight have longer and more cross-linked arms which make them more effective at connecting with more particles in the tailings.

50 Flocculants formed from ethylenically unsaturated water-soluble monomer or a blend of monomers were well known as at the priority date.

51 Commercially available flocculants as at the priority date could be formed from:

(a) monomer(s) selected from the group consisting of (meth)acrylic acid, allyl sulphonic acid and 2-acrylamido-2-methyl propane sulphonic acid as the free acids or salts thereof, optionally in combination with non-ionic co-monomers, selected from the group consisting of (meth)acrylamide, hydroxy alkyl esters of (meth)acrylic acid and N-vinyl pyrrolidone;

(b) monomer(s) selected from the group consisting of (meth) acrylamide, hydroxy alkyl esters of (meth) acrylic acid and N-vinyl pyrrolidone; and

(c) monomer(s) selected from the group consisting of dimethyl amino ethyl (meth) acrylate methyl chloride, (DMAEA.MeCI) quat, diallyl dimethyl ammonium chloride (DADMAC), trimethyl amino propyl (meth) acrylamide chloride (ATPAC) optionally in combination with non-ionic co-monomers, selected from the group consisting of (meth) acrylamide, hydroxy alkyl esters of (meth) acrylic acid and N-vinyl pyrrolidone.

52 Dr de Kretser gave evidence that flocculants added to tailings in aqueous solution achieve the peak level of flocculation within 10 to 20 seconds after addition to tailings, or in even shorter time periods. After 1.5 minutes after addition, depending on the level of agitation, the level of flocculation (yield stress) would be significantly lower than that peak level. Other evidence was to the effect that an aqueous solution will typically take a few seconds to mix and flocculate the slurry.

53 As I have said, a flocculant (or polymer) is a substance, most commonly synthetic, which is added to slurries to produce flocculation. Flocculation is the aggregation of suspended particles into larger clumps called floccs which are then able to more readily separate from the suspension or slurry. Let me at this point distinguish between a coagulant and a flocculant.

54 Coagulation facilitates the destabilisation and then elimination of colloidal particles, which are insoluble particles suspended in water. In other words, it facilitates the aggregation of insoluble particles suspended in a solution, where they would otherwise be evenly distributed. Coagulants do so by neutralising or “screening” the like charges of suspended particles, preventing repulsion between the particles, and facilitating either attractive forces (for example van der Waals forces) or bonding between the particles. Coagulation can form bonded flocs of particles, however, these flocs are less dense and less extensive than flocs created by flocculation.

55 Flocculation tends to be used where colloidal particles are already destabilised (i.e. the particles are not evenly dispersed in a solution, whether by coagulation or otherwise). Flocculants assemble the destabilised colloidal particles into aggregates. Flocculants, being long polymer chains, fix the destabilised particles and aggregates along the polymer chain, generally via ionic or hydrogen bonding. Properties of the flocculant used will depend on the nature of the solution. Anionic (negatively charged) flocculants “donate” negative charges to the suspended particles and cationic (positively charged) flocculants “donate” positive charges to the suspended particles.

56 The following discussion with Dr de Krester is also relevant:

MR SHAVIN: His Honour asked a question of me when we were opening the case as to the difference between a coagulant and a flocculant. Could you perhaps explain to his Honour what the difference is?---Typically a coagulant is a reagent which is – has the purpose of creating small flocs. So it would – I mean, probably the best thing is to consider it in contrast to a flocculant, which is a large, long chain polymer, which has the objective of grabbing particles and pulling them together into a more open floc. A coagulant is typically creates flocs, but they’re denser, less extensive. So there’s – so coagulation versus flocculation is typically characterised by the extent and size of the particle or the floc that you form, but also the types of reagents differ in the ones that are used to coagulate versus flocculate. So coagulation could be via changing the charge between particles, so they just – so simply the particles attract each other.

HIS HONOUR: So if you’ve got particles that have the same charge and would otherwise repel if you added a mineral salt or something - - -?---That’s – that’s correct.

- - - you would neutralise the charge, which will allow them to aggregate and create the small flocs?---Yes. And so some cases coagulation can be induced just by the concentration of sale in a suspending fluid.

Yes?---And what that actually does – you can still have like charge particles, but the repulsion between them is screened out because you have a lot of other ions.

Yes?---And they get sufficiently close that there’s – I’m not sure if you’re familiar with Van der Waals forces.

Yes, I am. Yes?---So that attractive force can actually – they can approach close enough that they – they reach what – what’s called an attractive minimum. So that’s one method of coagulation. There are also more, I guess, physical coagulants, in the sense that a reagent is added which precipitates and actually sticks, essentially, particles together. And there’s also the case of organic coagulants, which are polymers, but they’re smaller, shorter chain polymers, so they typically act maybe of around 100,000 molecular weight, compared to bridging polymers, which might be upwards of a million molecular weight.

So for a coagulant in some cases it can bond with the particles, but with all flocculants there is that bonding with the interaction of the polymer?---Yes. Yes. With flocculants there’s typically a physical absorption component to it.

Yes?---Coagulants can - - -

May be?---Can be electrostatic or physical.

Yes?---And typically coagulants – or coagulants are commonly used in conjunction with flocculants, but they can also be used in isolation as well.

57 Let me return to flocculants and elaborate further. As I have said, flocculants are composed of long chains of monomers that have been chemically bonded. When activated, flocculants have an elongated chain-like structure containing sites which can bind to solid particles when added to a suspension of particles in fluid. When a flocculant in aqueous solution mixes with a suspension, the flocculant chains adsorb or bind to the particles, aggregating them into flocs. Due to their increase in effective size, the flocs settle faster under gravity than the primary particles alone, increasing dewatering rates.

58 Flocculants have a wide range of chemistries and characteristics and the choice of the particular chemistry and characteristic of the flocculant is made on the basis of achieving the desired aggregation of particles in the system in question.

59 Conventional flocculants available before the priority date were typically a combination of polyacrylamide and polyacrylate monomers in a range of molecular weights. As I have said, molecular weight is determined by the length of the flocculant chain and affects the solids capture ability of the flocculant. Longer flocculant chains (having a higher molecular weight) have more active sites with which to trap solid particles. Higher molecular weight flocculants were also more viscous. Polyacrylamide was a well known form of flocculant that had a high molecular weight.

60 Further, as I have said, flocculants can be anionic, cationic or non-ionic, but the majority of flocculants used in mineral processes before the priority date were either anionic or non-ionic.

61 Flocculant was most commonly delivered to site in dry powder or emulsion form due to the lower transport cost and its more stable storage characteristics. Flocculants were rarely delivered to site in liquid (aqueous) form.

62 Irrespective of the physical form in which a flocculant was delivered, its use in practice in many cases required the flocculant to be converted into aqueous solution.

63 In dry powder and (to a lesser extent) emulsion form, the chains in a flocculant will be tightly coiled. In order for a flocculant to perform effectively, the flocculant chains must be dissolved in water and fully uncoiled so as to maximise the available binding sites. The preconditioning to achieve this state depended on the physical form of the flocculant. In particular the following may be observed:

(a) Powder flocculant was added, sometimes with a wetting agent, to process water in a mixing device before storage in conditioning tanks to allow time for the powder to dissolve and for the flocculant chains to uncoil.

(b) Emulsion flocculant was supplied as a water-in-oil emulsion i.e. droplets of concentrated flocculant solution in an oil carrier. Prior to use, the emulsion was inverted in a mixing device to release the concentrated flocculant solution into process water. The inverted flocculant solution was then transferred to conditioning tanks, again to allow time for the flocculant chains to uncoil.

(c) Liquid (aqueous) flocculant could be supplied in a fully dissolved state such that it could be used directly from the source tanks on delivery. This avoided the need for a flocculant preparation plant, but increased transport cost per unit weight of flocculant, effectively limiting its economic viability to low tonnage / low dosage operations. The supplied flocculant could be more concentrated than required by the application to reduce transport costs, and could be diluted before addition as required.

64 In most cases, the activated flocculant was then added to the tailings from the conditioning tanks with a level of dilution dictated by the application. Typically, for thickening applications, this dilution was by a factor of 10.

65 Further, different forms of water soluble flocculant required different activation times in water. In particular, dry powder flocculant required the longest activation time, flocculant in an emulsion required a shorter activation time and flocculant added in aqueous solution required no activation time at all.

66 If flocculant was added to tailings in a fully activated solution, it would begin flocculating within a few seconds.

67 As I say, when the flocculant was supplied in dry powder form it was mixed and aged in a mixing tank prior to addition to the thickener or thickener underflow to allow the flocculant to unravel and convert to an aqueous solution.

68 And as I say, when the flocculant was supplied in emulsified form, the normal practice would be to invert or “flip” the emulsion and turn it into an aqueous solution prior to addition to the thickener or thickener underflow.

69 The expertise and equipment necessary to convert flocculant from either dry powder or emulsified form to aqueous solution were present at most mine sites. Flocculant was commonly added in aqueous solution to thickeners, belt presses, and centrifuges. After preparation of the flocculant into aqueous form, the prepared flocculant was generally diluted prior to addition to thickeners, belt presses, and centrifuges. Dilution was required to reduce flocculant viscosity and enhance dispersion or mixing of the flocculant solution into the tailings. This facilitated efficient flocculant-particle interaction.

70 Let me now say something about dose point. A key factor to consider in the operation of thickeners, belt press filters and centrifuges is the location at which the flocculant was added. It was important to take the dose point into account to enhance the performance of the equipment and therefore to improve the characteristics of the tailings when discharged in the deposition area.

71 It was necessary to determine the appropriate point at which there was sufficient time after the flocculant was added for it to fully mix and react with the tailings, but not so much time as to allow shear forces to break down the flocs that were formed prior to the point where the material reaches deposition.

72 As to dosage, the following may be noted. The dose used to treat a mineral suspension in a thickener would have a significant influence on the strength of the tailings material in that it would have a higher yield strength.

73 Generally speaking, provided there was adequate mixing, the greater the dose of flocculant the greater the flocculation.

74 The size of flocs formed after flocculant addition was affected by the dosage. It was known that if larger flocs were desired, with a concomitant increase in dewatering rate, a larger dosage of flocculant would typically be required.

75 The addition of flocculants to tailings slurries can significantly change their rheology and dewatering properties. This can result in a slurry that has a higher viscosity, higher yield stress, higher compressive strength and increased permeability due to an increase in the effective particle size caused by the aggregation of fine particles in the slurry. The resultant change in rheology and dewaterability was a function of the dose of the flocculant. Larger doses of flocculant could result in a larger improvement in permeability, but with a stiffer particle network (i.e. increased yield stress at a fixed solids concentration).

76 The appropriate flocculant dosage for a particular application varied significantly based on the following factors which were idiosyncratic to each mine site:

(a) desired performance e.g. settling rate, settled density, shear sensitivity / robustness;

(b) flocculant type and process water chemistry;

(c) combination with other conditioning reagents e.g. inorganic coagulants, dewatering aids;

(d) solids particle size distribution;

(e) solids particle composition / mineralogy;

(f) solids concentration at point of addition;

(g) shear conditions at and after point of addition; and

(h) number of different points of floc addition.

77 At this point it is useful to say something about a number of fundamental material properties which govern the flow and dewatering of tailings irrespective of the method of treatment or transport of the tailings, again drawing from some of the evidence given by Dr de Krester.

78 Let me begin with rheology. The rheology of the slurry refers to its viscosity and flow characteristics.

79 The viscosity is a measure of the consistency of a slurry which governs the amount of energy required to make the slurry flow from one point to another. A low viscosity material such as water will flow readily whereas a more viscous material such as mud (or honey) requires more energy to make it flow.

80 In the case of suspensions of particles in liquid, in addition to having elevated viscosities, the slurries can exhibit a yield stress. Yield stress describes a stress level which must be exceeded before flow can be initiated. For example, toothpaste will not flow unless a sufficient force is applied to it - that amount of force is the yield stress of the toothpaste. Yield stress is measured in pascals (Pa) (i.e. force, in newtons, per square metre). The presence of a yield stress is an indication that an interconnected network exists between the particles within a material. This interconnection could be via attractive forces sticking particles together in the slurry, or simply due to the interlocking of particles as the solids concentration increases to the point where they can no longer move freely relative to one another.

81 Let me now turn to dewatering. The primary physical properties that govern the dewatering of any slurry are its permeability and its compressive behaviour.

82 The permeability of a slurry is governed by the friction generated when solid and liquid particles move relative to each other within the slurry. At low solids concentration (i.e. settling), the solid particles can be considered as moving within a liquid continuum. At high solids concentrations, the liquid can be considered as moving within a solid continuum, such as would be the case in filtration or consolidation within a tailings storage facility (TSF). Therefore, permeability governs the rate at which liquid can be expressed or separated from the solid particles in a dewatering operation.

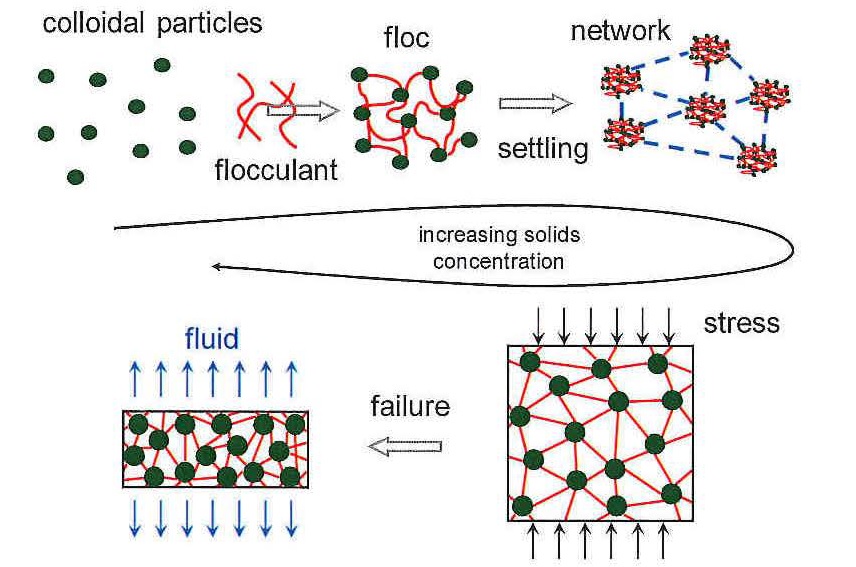

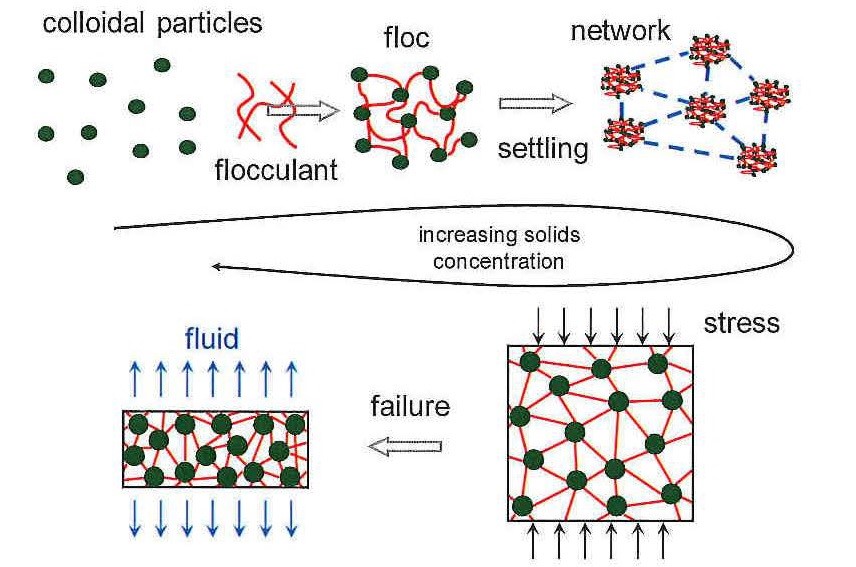

83 A schematic illustrating the range of solids concentrations and inter-particle structures over which the concept of permeability relates to is set out below:

84 The top section of this diagram shows flocculant acting on colloidal particles to form a floc, and ultimately a network of flocs within the material. Once the network has been formed, the application of a stress (for example by the weight of overburden generated by the addition of further material above) compresses the network causing the release of fluid (i.e. further dewatering of the deposited material). Permeability affects the rate of dewatering of the material across the entire spectrum of states depicted.

85 In simple terms, a highly permeable slurry will release water faster than a less permeable slurry; this is the case in thickeners, filters or on TSF deposition.

86 Let me elaborate on compressive behaviour. As the solids concentration of a slurry is increased, a point is reached where the solid particles within the slurry become interconnected. At this point, a solid particle network exists which has an integral strength which can withstand application of an external force (the yield stress). This condition could be generated either through dewatering of a slurry (e.g. sedimentation) or through the modification of inter-particle forces and structure within the slurry, or the addition of more solid particles to the slurry.

87 The compressive behaviour of a slurry refers to the ability of this network of particles to rearrange under the influence of an external force, thereby expressing liquid from between the particles. To facilitate compressive yielding of this network of particles at a particular solids concentration, an external force must be applied that exceeds the integral strength of the network (this is sometimes termed the “compressive yield stress”). At this point, the network will compress to a higher solids concentration with a higher integral strength. Ultimately, the compressive behaviour of a solid-liquid mixture governs the ultimate amount of liquid which can be expressed or removed from the mixture in a dewatering operation.

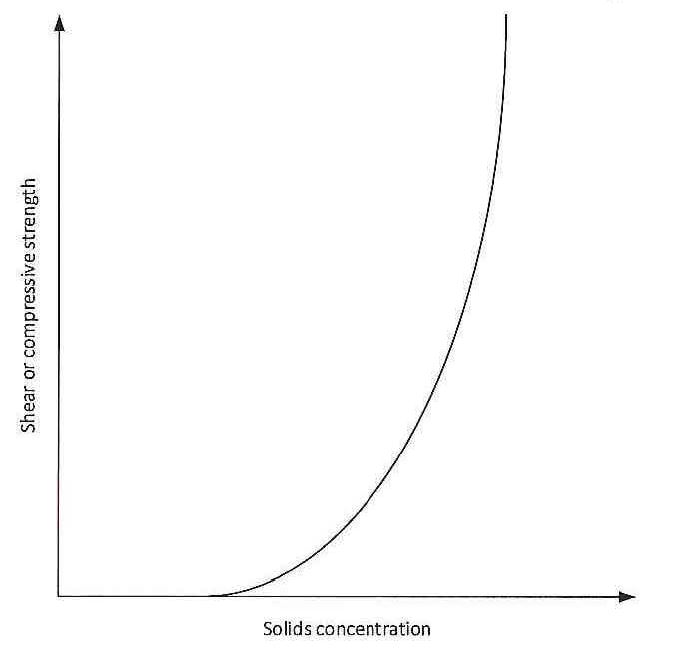

88 The diagram below illustrates the typical trend in network strength (compressive yield stress or shear yield stress) with increasing solids concentration. This shows that as the solids concentration increases, a point is reached where the strength of the material rapidly increases due to the interaction between the particles within the mixture.

89 There are various factors which significantly affect the rheology and dewatering characteristics of tailings slurry, both within dewatering equipment in a mineral processing plant (i.e. thickeners, filters, centrifuges) as well as within the TSF (i.e. water release upon deposition and long term consolidation after placement).

90 First, a higher solids concentration will usually result in a slurry with a higher viscosity, higher yield stress and a higher compressive strength. This is related to an increase in the number of collisions or interactions between particles under flow or in dewatering.

91 In terms of permeability, a higher solids concentration will result in a lower permeability. This is because the more solid particles in the slurry, the less available space for liquid to flow between those particles.

92 Viscosity, yield stress, compressive strength and permeability are all strong functions of slurry solids concentration.

93 Second, for the same material, a finer particle size distribution will generally have a higher viscosity, higher yield stress, higher compressive strength but lower permeability than a coarser particle size distribution. The lower permeability is due to the more tortuous flow path between or by the particles in the finer suspension. However, the finer particles increase the strength of the network (more particle interactions per unit volume) which in turn produces a higher yield stress.

94 In addition, the relative amounts of coarser and finer material within a size distribution can affect the packing of the particles in the slurry, and therefore affect the viscosity, yield stress, compressive strength and permeability of the slurry.

95 Third, the composition of dissolved ions within the process water influences the interaction between fine particles in the slurry and can result in attractive or repulsive forces between them. This can result in a slurry with a higher viscosity, yield stress and compressive strength due to a stronger inter-particle network (attractive forces). Conversely, a slurry with lower viscosity, no yield stress or compressive strength can be generated with repulsive forces between the particles. In terms of permeability, attractive forces typically promote fine particle aggregation, with a resultant increase in permeability at a given solids concentration.

96 Fourth, the type of minerals present within the tailings particles can have a strong influence on slurry rheology and dewatering. In particular, clay minerals were well known sources of increased viscosity in tailings slurries due to their plate-like structure and high surface area to particle volume ratio. Shear yield stress varies for a range of mineral tailings slurries with varying mineralogy, water chemistry, particle size and shape.

97 Fifth, the addition of chemical modifiers to tailings slurries can significantly change their rheology and dewatering properties, largely based on whether they promote attraction or repulsion between the particles.

98 This can either result in a slurry that has a higher viscosity, higher yield stress, higher compressive strength (with attraction), or is less viscous, has a lower yield stress and a lower compressive strength (in the case of repulsion). In terms of permeability, higher levels of attraction between particles typically results in increased permeability due to an increase in the effective particle size caused by the aggregation of fine particles in the slurry. This effect was the primary objective of the use of polymer flocculants in slurry dewatering (either within a thickener, filter, centrifuge or on deposition in a TSF). In the case of flocculant addition in particular, the resultant change in rheology and dewaterability was a strong function of the dose of polymer. It was known that larger doses of flocculant could result in a larger improvement in permeability, but with a stiffer particle network (i.e., increased yield stress at a fixed solids concentration).

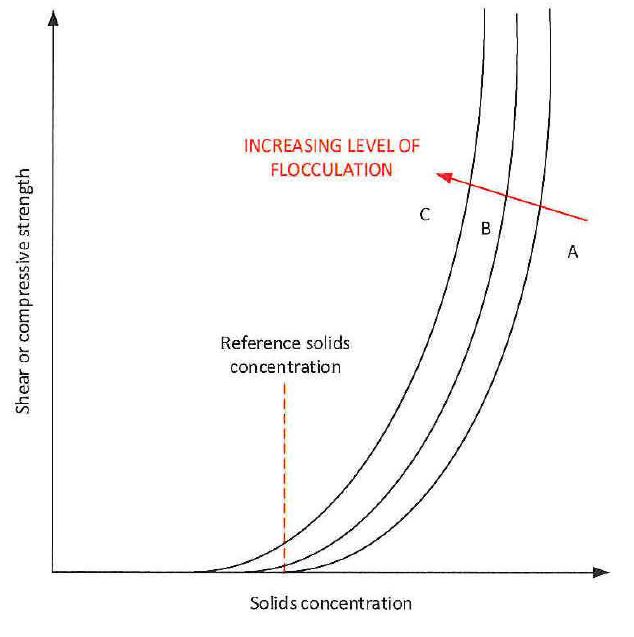

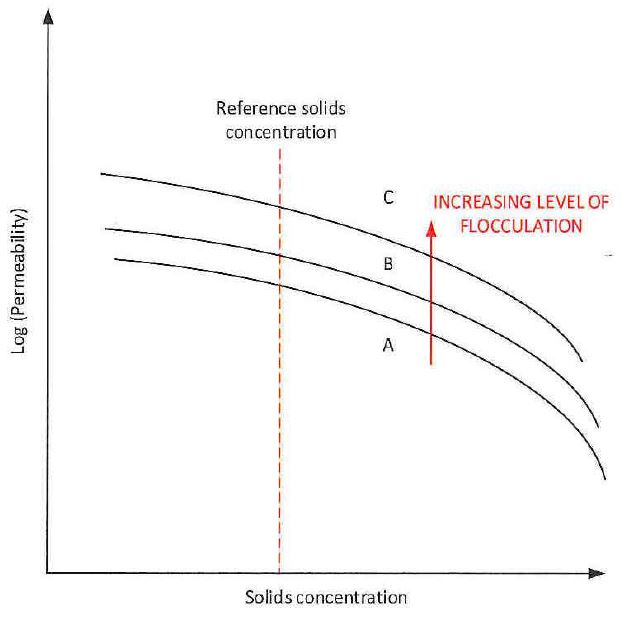

99 The changes in both permeability and network strength with increasing levels of flocculation are illustrated in the graphs set out below. In these graphs, permeability and network strength behaviour for three states of flocculation are conceptually depicted. State A represents a material that is unflocculated. State B represents a material that is moderately flocculated. And State C represents a material that is heavily flocculated. As can be seen in the graph on the left, the more flocculated that a material is, the higher its shear or compressive strength at a fixed solids concentration. As can be seen in the graph on the right, the more flocculated the material is, the higher the permeability for a given solids concentration. Typically, a permeability graph as depicted on the right is logarithmic, such that the changes induced by flocculation as illustrated can result in improvements of factors of 10 (or greater) over unflocculated material.

100 Sixth, slurries can exhibit changes in their rheology and de-watering behaviour as a function of the level of shearing they experience. The presence of shear dependency in a slurry can be related to the chemistry, mineralogy, particle shape or presence of additives in the slurry.

101 In particular, for slurries subject to polymer flocculation, the flocculated network generated by the flocculant, is highly shear sensitive such that exposing the slurry to shear can degrade the flocculated network. This degradation is irreversible (without the addition of further flocculant) and would typically lead to reductions in viscosity, yield stress, compressive strength and a significant reduction in permeability.

102 Let me say something further about yield stress at this point. Flocculants increase the yield stress of a mineral slurry. Yield stress is a measure of the strength of the slurry. That is, the ability of the slurry to withstand the application of applied force such as shear.

103 The yield stress of the slurry is critical to both the pumping of the slurry to a deposition area (such as a tailings dam) and the behaviour of the slurry on deposition.

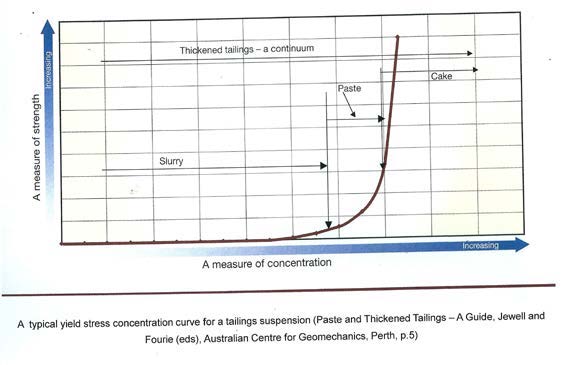

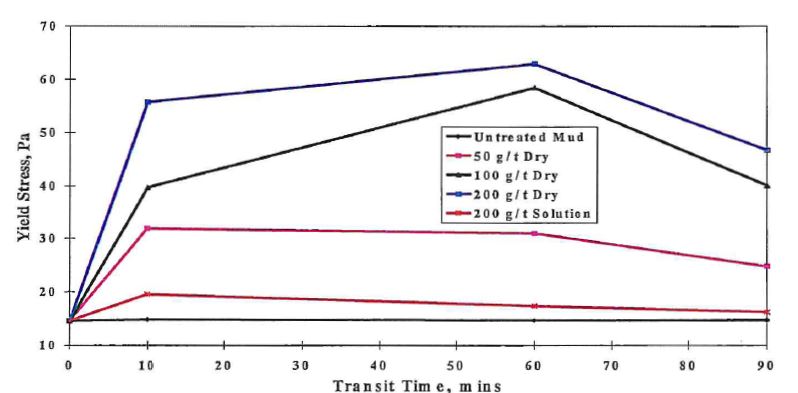

104 Typically, the greater the amount of flocculant used, the greater the yield stress of the slurry at a given concentration, as demonstrated in the diagram set out below. As the concentration of solids in the slurry is increased the slurry becomes less fluid-like and starts to become paste-like (like toothpaste or peanut butter) and ultimately, at high concentration, becomes solid-like (a cake).

105 Pumping a slurry with a higher yield stress will require more energy to pump than a slurry with a lower yield stress. However, as discussed below, pumping the slurry also exposes the slurry to shear forces, which causes flocs to break down and for the yield stress to decrease.

106 Let me now say something about pumpability and shear thinning. The distance between the thickener or treatment plant and the deposition area could vary from tens of metres to many kilometres depending on the particular mine. Therefore the time the thickened tailings were in transit from the thickener or treatment plant to the deposition area could vary from seconds to hours.

107 A common speed at which slurries were pumped was between 1 to 2 metres per second, depending on the material being pumped. Therefore, if the material was being pumped 300 metres the transit time was between 2.5 and 5 minutes. Whereas if the material was being pumped 10 kilometres, the transit time could be in excess of 2.5 hours.

108 However, the pumping of the tailings, particularly over long distances, could cause flocs formed in the tailings to break up and for the tailings to become more fluid with a decreased viscosity (often referred to as “shear thinning”). This shear thinning was a function of the mineralogy of the tailings, turbulence in the outlet pipe, the time that the floc structure was subjected to that turbulence and/or the sensitivity of the floc structure to such shear forces.

109 The distance the slurry is pumped (and therefore transit time) will also influence the amount of shear thinning that occurs. The distance (and therefore transit time) from the mine site to the point of deposition varied according to the mine and mineralogy involved. The distances involved can be measured in kilometres. The transit time from the thickener to the point of deposition could be very short and take only a few minutes or 60 minutes or longer depending on the setup of the mine site.

110 Shear thinning would typically lead to reductions in viscosity, yield stress, compressive strength and a significant reduction in permeability of the tailings on deposition in the deposition area.

111 Consequently, even if the slurry had a yield stress that was suitable for stacking on deposition when it exited the thickener, that yield stress would inevitably be significantly reduced when the slurry was pumped to the deposition area by virtue of the flocs being broken down by shear thinning.

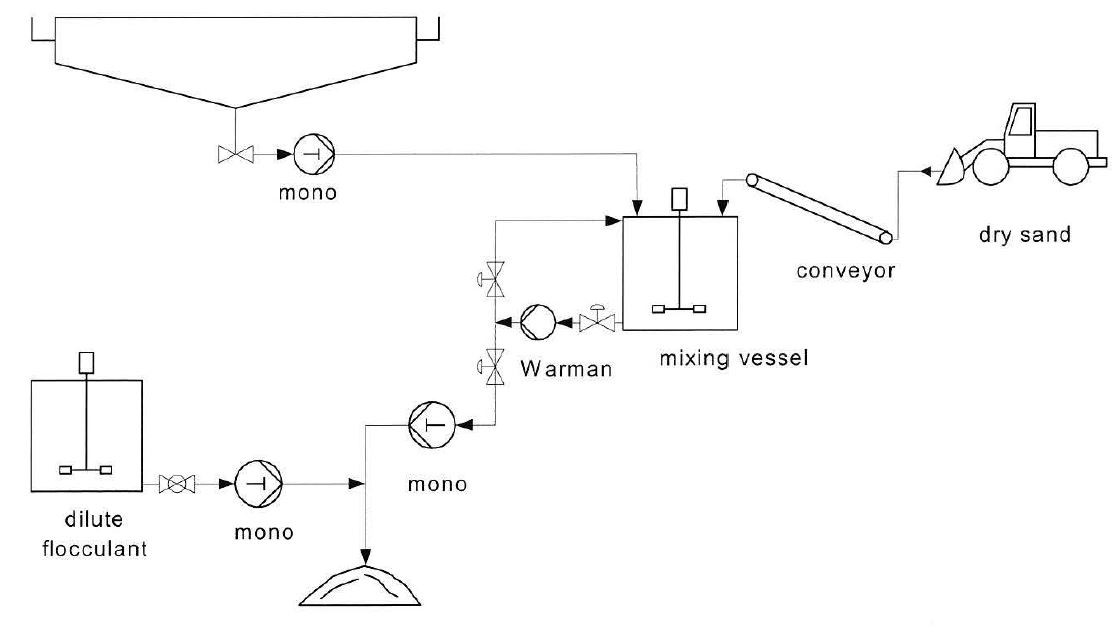

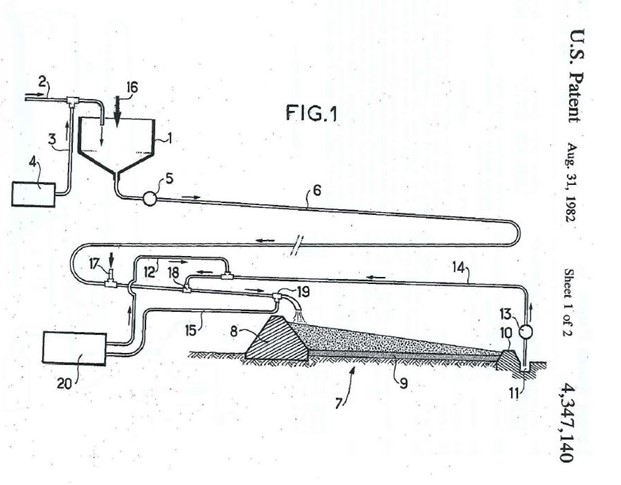

112 Let me say something about holding vessels. One practice undertaken prior to the priority date was to temporarily divert some of the flocculated tailings to a holding vessel before pumping the diverted tailings to the deposition area.

113 Diverting some tailings to a holding vessel was undertaken for a variety of operational and logistical reasons including generation of sufficient material to achieve the required coarse/fine blending requirements or for the addition and conditioning of chemicals or other additives to the tailings which required time. Furthermore, plant logistics may have required a certain volume of tailings to be deposited at a particular time or over a particular timeframe requiring storage or accumulation of tailings in the interim.

114 Further, one could subject liquor released from deposited tailings to further processing to reclaim or re-use any valuable dissolved materials.

115 At this point let me elaborate further on the question of dewatering and various devices.

116 Dewatering screens were a class of dewatering device where solids were retained on a perforated screen, whilst liquid drained through the apertures, enabling dewatering. The aperture size was selected based on the size of the particles in the feed slurry. The drainage was either driven by gravity (a gravity drainage screen) or an acceleration force provided by a vibrating screen (a vibrating dewatering screen).

117 If the feed slurry contained free solids that were smaller than the screen aperture size, the water released from the screen was dirty and would typically require further treatment. A dewatering screen required rapidly dewatering, free-draining solids and as such was typically employed in coarse tailings dewatering.

118 Alternatively, fine particle systems were treated on gravity drainage screens after application of dosages of polymer flocculant. This created a strong, granular, freely draining floc structure that released water rapidly on the screen (typically similar to the structure developed for in line flocculation and belt press filtration). Inclination of the screen resulted in solids movement down the screen, and ploughs were often employed to gently shear/densify the flocs and enhance water release. Alternatively, a screen could be in the form of an inclined rotating cylinder, whereby a gentle tumbling action promoted floc densification and water release. Gravity drainage also formed the critical initial dewatering phase of operation of a belt press filter.

119 Adoption of dewatering screens was characterised by:

(a) low technical complexity and capital cost, although vibrating screens would often only be one component of the full tailings management system;

(b) consideration of additional filtration for fines present in water released;

(c) potential requirements for conveying and trucking to the TSF;

(d) reducing costs for TSF development and management with increasing ultimate placed solids concentration; and

(e) improving water efficiency and environmental credentials proportional with the ultimate placed solids concentration.

120 Further, cyclones were commonly used in mineral processing to fractionate particles in a slurry into a coarse and fine fraction. Use of dewatering cyclones was commonly employed at operations where predominantly sand-sized tailings were generated e.g. in the mineral sands industry. A cyclone essentially was a cylindrical vessel with a tapered conical base in which a slurry was tangentially injected such that a swirling flow was generated. Due to ‘centrifugal force’, coarser particles would migrate faster to the outside of the vessel such that they moved downwards and were collected in an underflow stream at the base of the vessel. Fine particles moved in a flow pattern upwards and out of the centre of the cyclone in an overflow stream. Of course, anyone who has a modicum of physics education would know that the concept of “centrifugal force” is a fictitious outward force which is only apparent to observers in a rotating reference frame (e.g. a child on a playground roundabout). Rather, from an inertial reference frame, as materials enter the cyclone, the cyclone wall exerts a centripetal force towards the inside of the cyclone, which forces the slurry to undergo circular motion. Any object moving in circular motion is the subject of a centripetal force towards the centre. Think of it this way. An object in circular motion is accelerating. That is because its velocity is changing. Now its speed may be constant but its direction is changing. As velocity, a vector, is a function of speed and direction, an object in circular motion is changing velocity i.e. accelerating. And that acceleration, also a vector, is towards the centre. Force, also a vector, is a product of mass times acceleration. As the acceleration component (a vector) is towards the centre, with mass as a scalar concept, the force (centripetal force) is towards the centre. Now in the present context as the centripetal force applied is insufficient to keep the larger particles in circular motion, the radius of circular motion for such particles will increase until they migrate towards the outside of the vessel.

121 The natural behaviour of a cyclone was such that the water preferentially reported to the overflow with the fines, and the underflow contained coarse particles at a significantly higher solids concentration than in the feed. This natural dewatering effect could be enhanced by either the operating parameters or cyclone design, to promote enhanced dewatering of the cyclone underflow, such that a stackable, coarse output could be achieved.

122 Some ancillary treatment approach was required to deal with the dilute cyclone overflow stream containing fine material e.g. subsequent thickening or settling pond impoundment.

123 Adoption of cyclones was characterised by:

(a) low technical complexity and capital cost, however they would typically only be one component of the full tailings management system;

(b) the requirement of additional thickening / clarification for fines present in overflow;

(c) reducing costs for TSF development and management with increasing ultimate placed solids concentration; and

(d) improving water efficiency and environmental credentials proportional with the ultimate placed solids concentration.

124 Further, centrifuges were a dewatering technique whereby a slurry was placed within a rotating vessel which could be either solid (a solid bowl centrifuge) or with some kind of filter medium or screen at the base (basket or screen bowl centrifuge).

125 A wide range of centrifuge designs existed with differing rotational speeds, mechanical methods for solids discharge (e.g. via a helical scroll, scraping blade or plunger) and sometimes with additional vibration to enhance solids dewatering.

126 In general, centrifuges were less commonly used for tailings dewatering than other technologies. Vibrating basket centrifuges were most commonly used in fine coal dewatering, and solid bowl centrifuges were relatively commonly used in dewatering of industrial and municipal water and wastewater sludges, typically after heavy polymer flocculant dosage.

127 Adoption of centrifuges was characterised by:

(a) moderate technical complexity and capital cost;

(b) reducing costs for TSF development and management with increasing solids concentration; and

(c) improving water efficiency and environmental credentials proportional with the dewatered solids concentration.

128 Further, filtration was a dewatering technique where slurry was forced against a semi-permeable filter medium which resulted in retention of slurry solids on the medium as a filter cake, with passage clarified liquid (filtrate) through the medium.

129 A large number of different filtration technologies existed at the priority date such that it is impractical to provide an exhaustive list, but the broadest classification of filter types can be made based on the driving force for separation, which can be as a positive pressure or via application of a vacuum.

130 Pressure filters typically used for tailings dewatering at the priority date were most commonly recessed plate-type pressure filters, although pressure variants of disc and drum filters were also available.

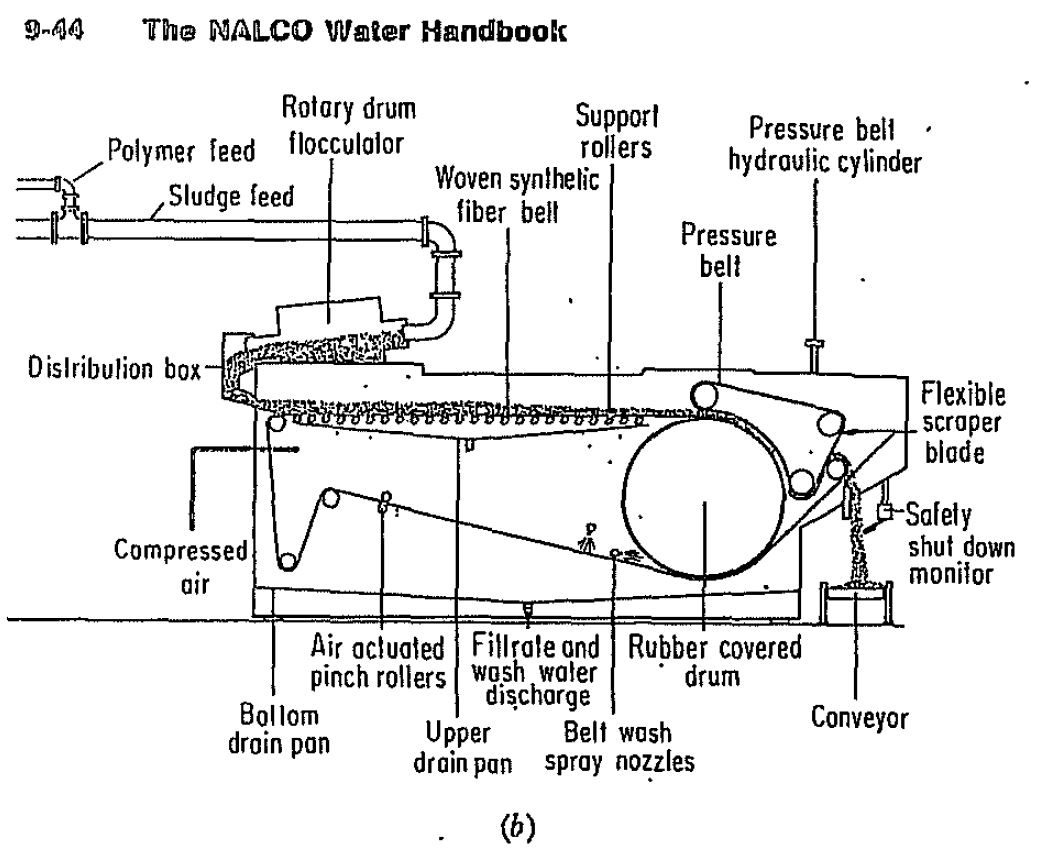

131 The belt press filter was also used for tailings dewatering and involved conditioning of thickener underflow with large doses of flocculant to produce freely dewatering slurry, with a “cottage cheese” structure. This then went through a gravity drainage phase followed by filtration under high pressure between two belts.

132 Successful operation of a belt press filter required the use of sufficiently high doses of flocculant to feed to produce the necessary freely dewatering “cottage cheese” like structure. This was necessary so that the material could be squeezed between the belts rather than being displaced by them.

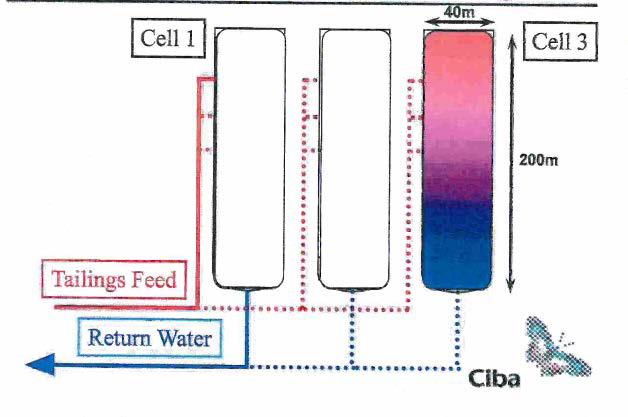

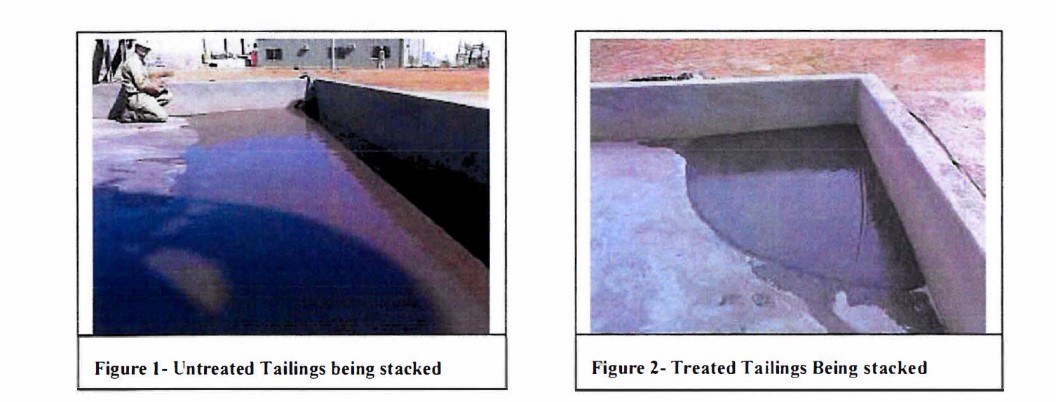

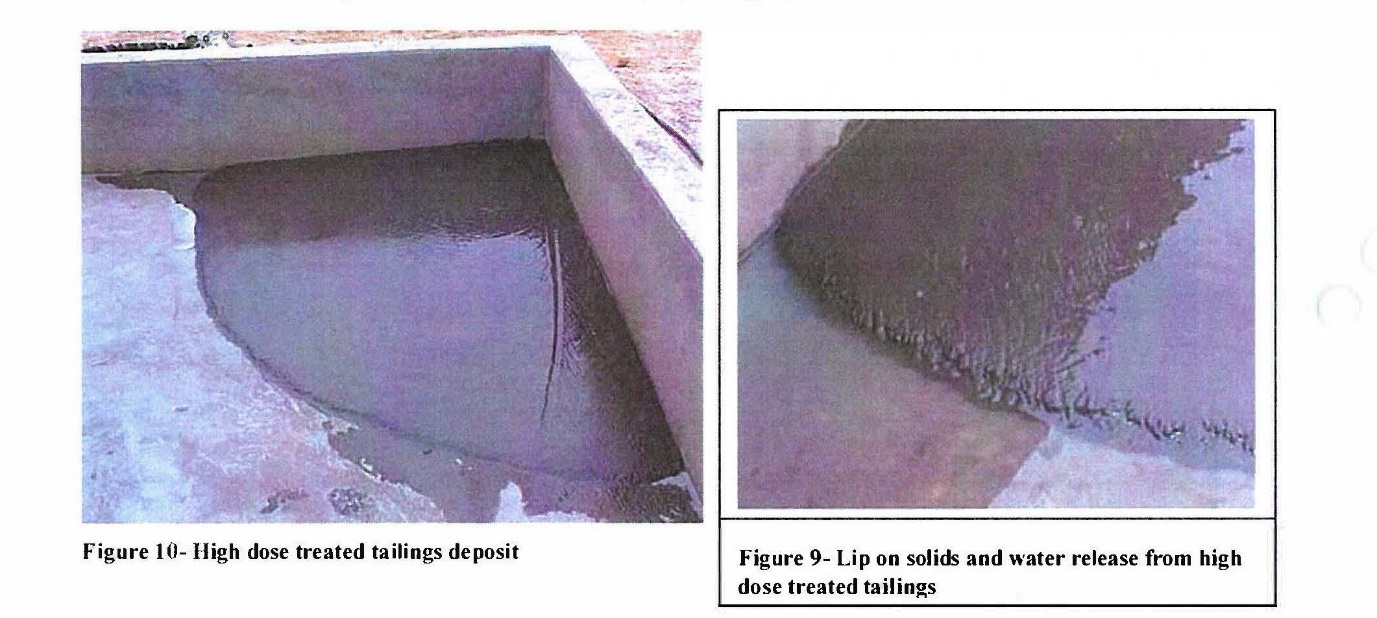

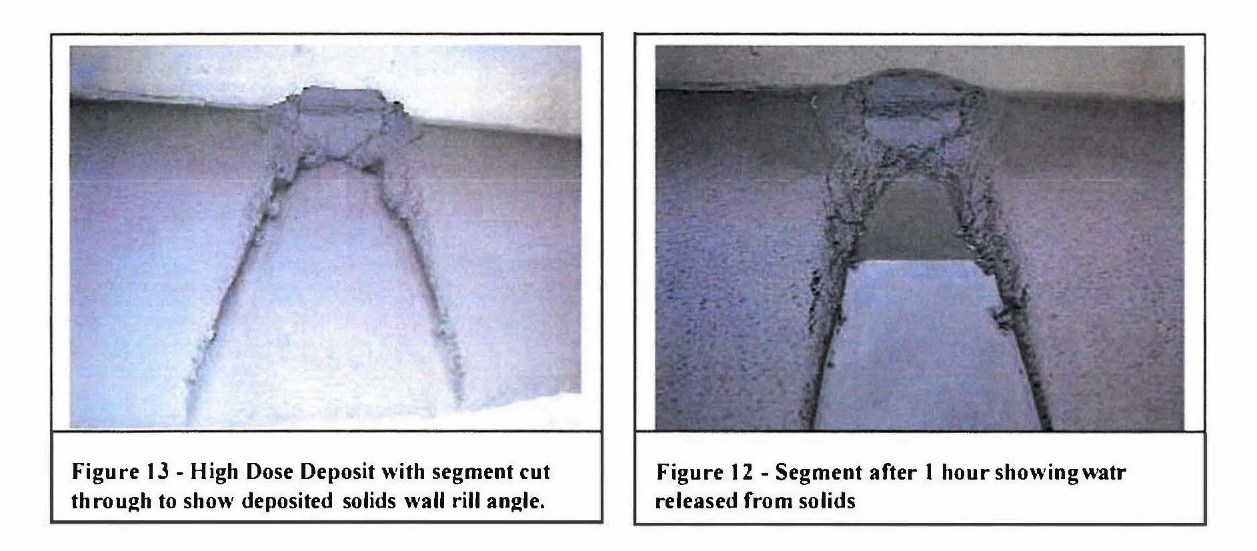

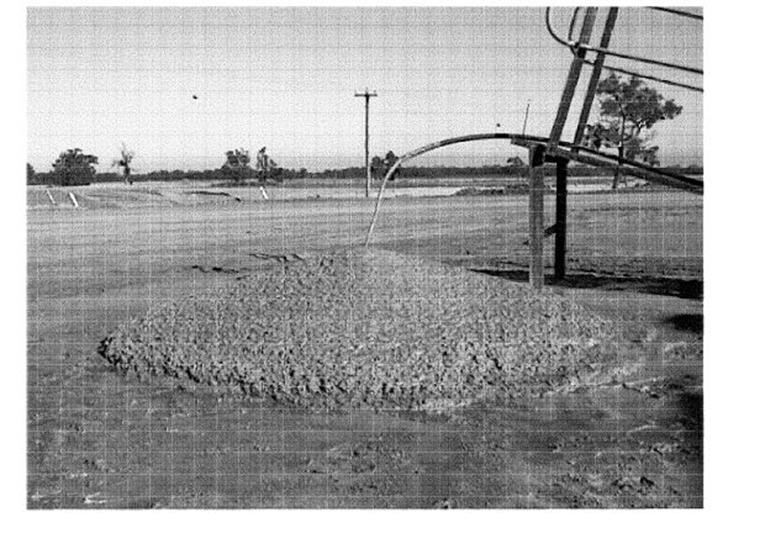

133 Let me now say something about tailings beaching.

134 Conceptually, beaches can form in two ways. For a homogenous slurry, where solid particles do not rapidly settle out, a beach forms as the slurry stops moving at some point after deposition due to its viscous nature overcoming the level of energy driving the spreading of the slurry. Alternatively, a beach could form due to material settling out from the slurry as it travelled outwards from the deposition point. In some cases, where a wide range of particle sizes were present within a slurry, differential settling rates could exist, with coarser particle settling faster than the finer ones. This could then result in coarser particles being deposited closer to the deposition point, with finer material travelling progressively further down the beach. In extreme cases, the beach may be formed predominantly of coarse material with fines migrating to the decant pond. In situations where separation of the particles from the deposited slurry was the driving force for beach formation, the rate of separation was driven by the particle settling rate (i.e. a measure of permeability), which in turn controlled the beach angle.

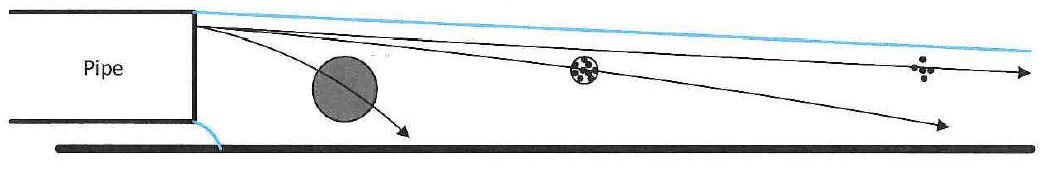

135 A schematic illustrating the impact of particle size on separation/settling of solids during deposition is set out below. This illustrates how larger, or denser particles or flocs will tend to be deposited closer to the exit of a discharge pipe than finer particles.

136 A flocculated structure at the point of deposition could enhance beach formation by either:

(a) binding fines to coarse particles to prevent segregation on the beach; or

(b) promoting more rapid separation of solids from the carrier fluid.

137 In the case of thickened or paste thickened tailings discharged into a deposition area, it was desirable for the deposited tailings to form a sloped beach in the deposition area.

138 For tailings deposited with perimeter discharge, development of a beach was desirable as it promoted run off of liquid expressed from the tailings into a decant pond for easy recycling. In addition, the integrity of the TSF embankment was also enhanced through the migration of liquid away from the area adjacent to the embankment. TSF embankments were typically not constructed as water retaining facilities due to a higher cost of construction (except in circumstances where a water cover over deposited tailings was required) and as such, the presence of large volumes of water against these structures could lead to structural failure.

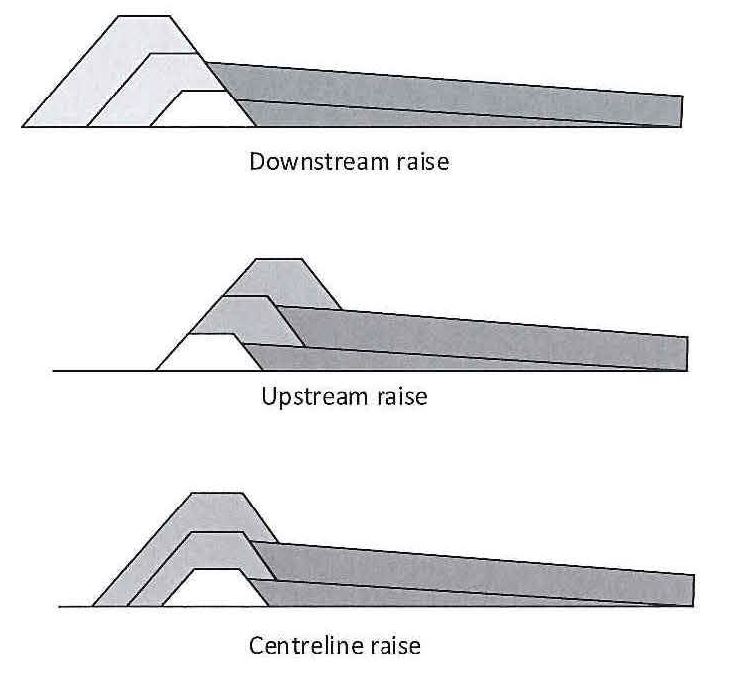

139 A further advantage of the development of a beach is that it allows the construction of further embankment walls on top of the beached material when the mine operator wishes to raise the dam wall. This method of construction is termed an “upstream raise”. Adopting this construction approach significantly reduces the cost of raising the dam wall, as the amount of construction material required is significantly reduced. For this to occur, the beached material needs a sufficient level of strength to support the overlying dam wall structure. As can be seen from the diagram below, the relative amount of material required for an “upstream raise” is significantly less than for a “downstream raise” or a “centreline raise”.

140 For the tailings deposited with central discharge, it was also desirable for the development of a sloped beach, which in this case would be a conical shape. The advantages of a sloped beach in such a case are to promote run off of rainfall to maintain the tailings in a dry state, and to allow storage of the maximum amount of tailings within the conical shape without either having to build a high confining embankment or to occupy a large area.

141 Generally, beaching of the tailings allowed for the storage of a greater volume of tailings for a given area of TSF, which was one of the goals of tailings management processes.

THE OPPOSED APPLICATIONS

(a) Background

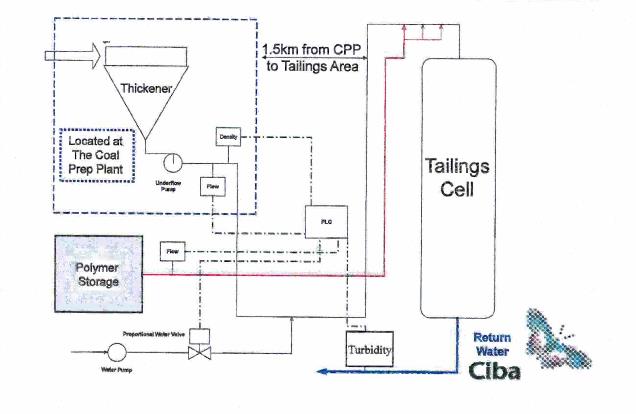

142 Let me address some background concerning the disposal of tailings.

143 Generally speaking, until about the mid to late 1950s water was not scarce and there were no restrictions on the dumping of wastes or use of tailings dams. Therefore a mine operator could usually obtain water from any easily available source and dump the tailings whenever convenient. This often meant using water from a river and dumping the wastes back into the river. Typically, mine operators simply deposited the tailings into pits, dams or rivers without further treatment or consideration of the environmental impact of the tailings, and without concern for recovering water from the tailings.

144 Prior to the 1980’s the most commonly used technique for dewatering of tailings involved the use of thickeners to recover some of the water from the tailings. To enhance the separation rate of the solid and liquid within a thickener, the generally accepted practice was to add a flocculant to the feed entering the thickener which aggregated the particles in the thickener and increased their settling rate. As the solids separated from the water in the thickener, clear water was taken from the top of the thickener. The solids removed from the bottom of the thickener were usually pumped in a slurried form to a deposition area. The deposition area could have been an existing mined-out pit, or a purpose built tailings storage facility.

145 A common method for disposing of thickener underflow was to deposit it onto a slope, wall or floor of a deposition area in order to beach the tailings, so that released water flowed to a lower point and could be pumped back to the plant for re-use (tailings beaching). A typical approach to tailings beaching was to deposit thickener underflow onto a slightly sloping surface, which enabled the material to build up on the slope with released water flowing to a lower point where it could be recovered for re-use in the mining process.

146 In the 1980s and 1990s in Australia, mine operators were faced with challenges in relation to environmental issues, water efficiency and limited land availability, and increased regulatory controls. Those factors and good economic reasons forced mine operators to look at ways to improve their tailings disposal processes.

147 As a result of these pressures, in the period leading up to the priority date, the mineral processing industry was focused on improving ways of disposing of tailings. Some objectives in the management of the treatment of tailings were to:

(a) minimise the amount of land that was taken up by the storage of tailings to create as small a footprint as possible;

(b) obtain a stable and trafficable deposit;

(c) maximise recovery of relatively clean water so that the water could be re-used in the plant; and

(d) rehabilitate the deposited tailings within an acceptable timeframe.

148 Further and in this context, the particular choice of tailings dewatering technique employed for a given operation was strongly influenced by the particular circumstances existing at any mine including:

(a) land availability and topography;

(b) water availability;

(c) environmental restrictions;

(d) access to power;

(e) distance to deposition area from plant; and

(f) available manpower.

149 At the priority date the most commonly used tailings dewatering techniques which involved the use of mechanical dewatering equipment included the use of thickeners/clarifiers, dewatering screens, cyclones, centrifuges, and filtration methods such as belt press filters, all of which involved the use of flocculants.

150 Co-disposal was also a technique used in some cases both to dispose of coarse waste materials and to assist in obtaining a stable deposit of tailings in the deposition area, including in tailings beaching. However, there were well known difficulties involved with co-disposal.

(b) The invention described in the 785 application

151 The field of the invention is described in the 785 application (p 1 lines 5 to 10) in the following terms:

The present invention relates to the treatment of mineral material, especially waste mineral slurries. The invention is particularly suitable for the disposal of tailings and other waste material resulting from mineral processing and beneficiation processes, including the co-disposal of coarse and fine solids, as a homogenous mixture.

152 The 785 application notes that in some cases the tailings could be back filled into mines. In cases where it was not possible to dispose of the waste in an emptied mine, it was common practice to dispose of the waste material by pumping the aqueous slurry to lagoons, heaps or stacks and allowing it to dewater gradually through the actions of sedimentation, drainage and evaporation. Page 1 lines 26 to 30 states:

For other applications it may not be possible to dispose of the waste in a mine. In these instances, it is common practice to dispose of this material by pumping the aqueous slurry to lagoons, heaps or stacks and allowing it to dewater gradually through the actions of sedimentation, drainage and evaporation.

153 The 785 application notes the environmental pressures to minimise the allocation of new land for disposal and to more effectively use the existing waste areas. A related environmental pressure was the efficient re-use of water in the mining process. Page 2 lines 1 to 4 states:

There is a great deal of environmental pressure to minimise the allocation of new land for disposal purposes and to more effectively use the existing waste areas. One method is to load multiple layers of waste onto an area to thus form higher stacks of waste.

154 The 785 application notes that it is desirable to have a treatment which provides a more rapid release of water from the deposited material and that the concentrated solids are held in a manner that prevents both segregation of any coarse and fine fractions and contamination of the released water, whilst minimizing the impact on the environment. Page 3 line 29 to page 4 line 2 states:

It would therefore be desirable to provide treatment which provides more rapid release of water from the suspension of solids. In addition it will be desirable to enable the concentrated solids to be held in a convenient manner that prevents both segregation of any coarse and fine fractions, and prevents contamination of the released water whilst at the same time minimises the impact on the environment.

155 The 785 application recognises that one method of reducing the area of deposition was to form stacks of “rigidified waste”. One “difficulty” identified in the 785 application was to ensure that the new waste flowed over previously “rigidified” waste, remained within the waste area boundaries, formed a stack and consolidated to support multiple layers without collapsing or overflowing. Page 2 lines 3 to 8 states:

One method is to load multiple layers of waste onto an area to thus form higher stacks of waste. However, this presents a difficulty of ensuring that the waste material can only flow over the surface of previously rigidified waste within acceptable boundaries, is allowed to rigidify to form a stack, and that the waste is sufficiently consolidated to support multiple layers of rigidified material, without the risk of collapse or slip.

156 The 785 application describes the common use of flocculants to assist in the disposal of tailings through the process of flocculation in a thickener so as to give higher density to the underflow and assist in the recovery of water. Page 2 lines 16 to 18 states:

These solids are often concentrated by a flocculation process in a thickener to give a higher density underflow and to recover some of the process water.

157 The 785 application also recognises that SDITB had been used to improve the compaction of the fine waste material and clarity of the recovered water. But the 785 application asserts that such processes applying flocculants at “conventional doses” had produced little or no benefit. Page 3, lines 21 to 27 states:

Attempts have been made to overcome all the above problems by treating the feed to the tailings dam using a coagulant or a flocculant to enhance the rate of sedimentation and/or improve the clarity of the released water. However, this has been unsuccessful as these treatments have been applied at conventional doses and this has brought about little or no benefit in either rate of compaction of the fine waste material or clarity of the recovered water.

158 Dr Farrow acknowledged that the reference to “feed to the tailings dam” in the 785 application encompassed thickener underflow. As he said, the most common way of feeding materials to a tailings dam was where the material had previously gone through a thickener.