Federal Court of Australia

Airco Fasteners Pty Ltd v Illinois Tool Works Inc [2023] FCAFC 7

ORDERS

Applicant | ||

AND: | Respondent | |

DATE OF ORDER: | 13 February 2023 |

THE COURT ORDERS THAT:

1. The appellant have leave to appeal from declaration 1 and orders 1, 2, 3, 4, 5, 6 and 7 made by the primary judge on 23 May 2022.

2. Within seven days, the appellant file and serve a notice of appeal substantially in the form of the draft notice of appeal (being annexure “KAH-3” to the affidavit of Kathryn Anne Howard dated 3 June 2022).

3. The appeal be dismissed.

4. The appellant pay the respondent’s costs.

Note: Entry of orders is dealt with in Rule 39.32 of the Federal Court Rules 2011.

[1] | |

[6] | |

[6] | |

[12] | |

[21] | |

[22] | |

[22] | |

[26] | |

[31] | |

[36] | |

[48] | |

[48] | |

[49] | |

[60] | |

[67] | |

[69] |

THE COURT:

1 These proceedings are brought as an application for leave to appeal and an appeal against a Declaration and consequential Orders made on 23 May 2022 to the effect that Airco Fasteners Pty Ltd has infringed claims 1, 2, 3, 17 and 20 (relevant claims) of Australian Patent no 2005232970 for the reasons set out in Illinois Tool Works Inc v Airco Fasteners Pty Ltd [2022] FCA 495 (judgment). The respondent is the patentee, Illinois Tool Works Inc.

2 The application for leave to appeal was necessary because, following a familiar course in many patent infringement actions, the issue of liability for infringement was heard separately and before the determination of the quantum of any relief. In such cases, it is generally appropriate for the Court to grant leave to appeal having regard to the fact that, as a matter of substance, the liability issues have been finally determined and it is convenient that any appeal is completed before questions of quantum are visited. Accordingly, leave to appeal is granted.

3 The Patent is entitled “In-can fuel cell metering valve” and describes a fuel cell for use with a combustion tool, such as a nail gun, which includes an internally mounted metering valve arranged such that a measured dose of fuel is dispensed each time the stem is pressed into the “open” position.

4 The appeal raises two substantive issues, being whether the primary judge erred in determining that the combustion tool fuel cell imported, supplied and sold by Airco (Airco Fuel Cell):

(1) has “a fuel metering chamber disposed in close proximity to said closure” (close proximity integer), as required by each of the relevant claims; and

(2) has “a valve body having a second end opposite said fuel metering chamber located within said container” (second end opposite integer), as required by each of the relevant claims.

5 For the reasons developed below, we find that the appeal must be dismissed with costs.

6 The judgment pellucidly distills the complex subject matter of the Patent, the evidence and the dispute into a comprehensive, but short and easily comprehensible analysis of the real issues. The primary judge summarises the background and prior art as follows:

12 The background to the invention is discussed in the first eight paragraphs of the Patent.

13 That section of the Patent first states that the invention relates generally to improvements in fuel cell delivery arrangements for use in combustion tools, and more specifically to metering valves used with such fuel cells for delivering the appropriate amount of fuel for use by a combustion tool during the driving of fasteners. It also explains that while the Patent focusses on fuel cells in combustion tools, the invention may also be applied to other pressurised containers using stem valves, such as those used in relation to cosmetics and pharmaceutical products.

14 The Patent refers to four US prior art patent specifications, each of which are said to be incorporated by reference into the Patent. One of these, US patent No 5,115,944, is later in the specification said to disclose the general construction of fuel cells. The prior art specifications disclose the use of mechanical or electronic valve assemblies designed to be able to control the amount of fuel that is dispensed from the fuel cell into the tool during each operation.

15 The Patent lists a number of “design criteria” it says are relevant to the design of fuel cells containing separate compartments of pressurised fuel and propellant.

16 First, the Patent refers to the prevention or minimisation of leakage of fuel and/or propellant. In particular, a stated objective is to prevent or minimise leakage of fuel and/or propellant after production and before use, also known as shelf life, and during periods when the fuel cell is installed in the tool but the tool is stored or otherwise not in use. The Patent notes that as with other aerosol or fuel canisters, a certain amount of leakage occurs over time. However, there is a concern that gradual leakage over a prolonged shelf life may result in reduced performance of the fuel cell due to insufficient propellant and/or fuel remaining for expected performance needs.

17 A second stated objective of the Patent is that only a desired amount of fuel should be emitted by the fuel cell for each combustion event.

18 The Patent refers to two further US patent specifications: US patent no 5,263,439, which discloses an internal-tool metering valve (where the metering valve is located internal to the tool housing and external to the fuel cell); and US patent no 6,307,297, which discloses an external metering valve (where the metering valve is “attached to the fuel cell” prior to the fuel cell being inserted into the tool housing). These metering valves are designed to control the amount of fuel emitted each time, for example, a nail gun is fired. These two additional specifications are also said to be incorporated by reference into the Patent.

19 The Patent emphasises that regardless of where the fuel metering valve is located, fuel leakage has remained a design consideration. In this context, it states that internal tool fuel metering valves have the disadvantage of requiring an excessive number of seal locations, which, in turn, provides more opportunities for fuel leaks. In order to facilitate disposability of external fuel cell metering valves, inexpensive materials are used. However, the aggressive nature of the fuel constituents may in some cases cause premature failure of the valve seals or the valve housing itself.

20 Another design consideration is said to be to avoid the duplication of components associated with external fuel cell metering valves, in that a first valve controls the flow of fuel from the cell, and a second valve controls a metered dose of fuel for delivery to the tool for a single combustion event. A related concern is the shipping of external fuel cell metering valves. The valves are shipped in an inoperative position and must be activated by the user by moving the valve into position. Fuel leakage from improper installation of the metering valve is a problem.

21 A further design consideration associated with cell-mounted metering valves is said to be that once the valve is operationally installed, the main cell stem valve is continuously open. The nature of the seal formed by the main fuel cell valve stem seal changes from a face seal to a radial seal about the valve stem, a more relaxed seal which proves less effective sealing and increases the potential for leakage.

7 The primary judge then refers to the summary of the invention and notes that against the background summarised above, including the incorporated prior art specifications, the invention disclosed in the Patent provides a fuel cell for use with a combustion tool which includes an internal metering valve, arranged such that a measured dose of fuel is dispensed each time the stem is depressed into the “open” position. The invention disclosed facilitates one or more of the fuel seals in the prior art internal-tool or external metering valves, which may have contributed to the total amount of leakage from the device, to be “designed out”. This has been done, the primary judge finds, by structurally changing the device so that the metering valve is located within the fuel cell housing, which in turn reduces the number of component connections and streamlines the flow of the fuel between the fuel housing and the tool. In addition, the primary judge notes that the disclosure of the invention provides that by locating the metering valve inside the fuel cell, the invention combines in a single unit the functions of two valves in the prior art fuel cells. It thereby reduces duplication of components, as the invention only requires one valve body, one biasing element (eg a spring) and one stem, and reduces the overall number of required seals compared to the prior art discussed in the Patent, which is said to reduce cost, increase reliability and make the invention more user friendly.

8 After referring to the description of 14 exemplary embodiments identified in the patent at [8a] to [8n], the primary judge refers to the description of the preferred embodiment, which features a metering valve internally mounted in the fuel cell, defined by a one-piece valve body, one end of which is located inside the inner fuel container located within the fuel cell. Her Honour notes at [27] that:

…it is by locating the metering valve inside the fuel cell housing (or can) that the valve usefully combines in a single unit the functions of the Prior Art standard fuel cell “check valve” and separate “external metering valve”.

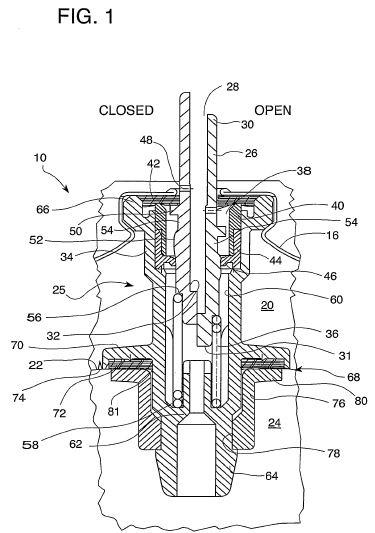

9 The primary judge then refers to the detailed description of the invention provided in the Patent, setting out Figure 1 (which, we interpolate, is described in the Patent as a split vertical cross-section of a combustion tool fuel cell provided with the present internal metering valve, shown in closed (left) and open (right) positions) as follows:

10 The primary judge provides a description as follows at [30]:

In the brief summary section, the Patent explains that the function of the fuel metering chamber (38) is to facilitate the storage and subsequent dispensation of a measured amount of fuel through the outlet of the fuel cell. In the preferred embodiment depicted in Fig 1, the fuel metering chamber engages an outlet seal, which is adjacent to the closure (16) of the fuel cell. However, the Patent explains that the fuel metering chamber may be located within the housing and is preferably located within the valve body (34) and in close proximity to the closure. Locations external of the valve body (34) are also expressly contemplated.

11 The primary judge then sets out the following paragraphs of the Patent, which were referred to in argument before her in the context of the construction of the second end opposite integer (emphasis added by the primary judge):

[20] A main valve stem 26 is configured for emitting fuel from the container 22 and as such has an outlet 28 at a first end 30 projecting from the housing, and a second end 31 opposite the first end. The valve stem 26 is in fluid communication with the source of fuel, preferably the container 22, which is preferably flexible or compressible to accommodate pressure exerted by the propellant as fuel is consumed and the volume of the container accordingly reduced. The first and second ends 30, 31 are separated from each other, preferably by a passageway 32. To emit fuel, the main valve stem 26 reciprocates relative to the housing 12 within a valve body 34 under a biasing force, preferably exerted by a biasing element 36 such as a spring, between a closed position (shown on the left half of FIG. 1) and an open position (shown on the right half of FIG. 1). In the closed position, the main valve stem 26 is biased by the biasing element 36 to an extended condition. In the open position, the main valve stem 26 is pushed back or retracted in a way that overcomes the biasing force of the element 36.

…

[22] In the embodiment of FIGs. 1 and 2, the fuel metering valve 25 includes a fuel metering chamber 38 located within the housing 12. This configuration is intended to reduce components and/or to reduce unwanted leakage or emission of fuel, which are design issues with current fuel cells. Preferably, the fuel metering chamber 38 is located within the valve body 34, and more preferably in close proximity to the closure 16, however locations externally of the valve body are also contemplated. By incorporating the metering valve 25 so that the valve body 34 is located permanently inside the fuel cell 10, potential leakage areas at the engagement point of an external valve to the prior art main valve stem are eliminated. Also, potential dosage changes due to environmentally or hydrocarbon exposure-caused changes in external metering valve dimensions are also eliminated.

…

[25] In the closed position, the inlet 48 is no longer located within the fuel metering chamber 38, and is preferably external of the seal 42. Thus, in this position, fuel cannot enter the main valve stem 26. The at least one stop member 50 is positioned on the main valve stem 26 so that it engages the outlet seal 42 and prevents further movement of the valve stem past the closure 16. Another feature of the main valve stem 26 is a generally radially enlarged portion 52. The enlarged portion 52 is of sufficient diameter to sealingly engage the lip seal 46 and prevent the passage of fuel into or out of the entry of fuel relative to the fuel metering chamber 38. A standard or relatively narrow diameter portion 54 of the main valve stem 26 is located between the stop 50 and the enlarged portion 52. At the opposite end, the generally enlarged portion 52 gradually reduces in diameter to form a seat 56 for the biasing element 36. An opposite end of the biasing element 36 engages an end of a body cavity 60 in the main valve body 34 in which reciprocates the main valve stem 26.

…

[27] To facilitate the delivery of fuel to the metering chamber 38, the valve body 34 is secured to the container 22, preferably such that the valve body has a first end 66 engaging the closure 16, such as by being crimped, and the second end 62 having the nipple portion located within the container. It will be seen that the biasing element 36 is located in the valve body 34 between the second end 62 and the first end 66, the latter providing the location for the fuel metering chamber 38, which is opposite the second end 62. It is contemplated that variations of this disposition of the valve body 34 are suitable for achieving the goal of secure mounting of the valve body relative to the fuel cell 10 for support and for consistent fuel metering during tool operation.

12 The primary judge set out each of the relevant claims and also claims 21 and 22.

13 Claim 1 of the Patent claims (for convenience we have added integer numbers) (emphasis added):

(1) A fuel cell for use with a combustion tool, comprising:

(2) a housing defining an open end enclosed by a closure;

(3) a main valve stem having an outlet, disposed in operational relationship to said open end and reciprocable relative to said housing at least between a closed position wherein said stem is relatively extended, and an open position wherein said stem is relatively retracted;

(4) a fuel metering valve associated with said main valve stem, including a fuel metering chamber disposed in close proximity to said closure and configured so that when said stem is in said open position only a measured amount of fuel is dispensed through said outlet;

(5) said housing including a separate fuel container,

(6) wherein said fuel metering valve is located within said housing and includes a valve body having a second end opposite said fuel metering chamber located within said container, and (7) wherein the flow of fluid out the outlet of the fuel cell is solely from said separate fuel container.

14 The primary judge identified that it was the presence or absence of the two italicised integers set out above in the Airco Fuel Cell that was the issue in dispute in claim 1. Key to that dispute is the construction of the bolded terms above.

15 Claim 2 provides:

The fuel cell of claim 1, wherein said main valve stem has a radially enlarged portion, and said fuel metering chamber is provided with a lip seal constructed and arranged to engage said enlarged portion in said open position, but defining a fuel passage therebetween in said closed position.

16 Claim 3 provides:

The fuel cell of claim 1 or claim 2, wherein a first end of said valve body engages said closure.

17 Claim 17 provides:

A fuel cell according to any one of the preceding claims, wherein the fuel metering chamber is disposed in said close proximity to said closure such that the metering chamber is located closer to the open end of the housing than an end of the housing opposing said open end.

18 Claim 20 provides:

A fuel cell according to any one of the preceding claims, wherein the main valve stem is biased toward the closed position by a biasing element, and wherein the biasing element is located outside the metering chamber.

19 Claim 21 provides:

A fuel cell according to any one of the preceding claims, wherein the biasing element is located in the main valve body between the metering chamber and a lower end portion of the valve body that extends to the separate fuel container.

20 Claim 22 is an omnibus claim which claims a fuel cell for use with a combustion tool substantially as hereinbefore described with reference to the drawings.

21 The primary judge referred to the evidence of Dr Allan Wallace and Mr Graham MacDonald, respectively the experts called by Illinois and Airco, and their joint expert report (JER). Her Honour set out the principles relevant to patent construction, which are not substantially in contest in this appeal, before considering at [60] to [72] the characteristics and role of the person skilled in the art. In this regard, the primary judge considered that to the extent that the experts’ opinions could inform the determination of the issues before the Court, Dr Wallace’s opinion on technical matters should be preferred over those of Mr MacDonald. However, it is apparent from her Honour’s reasons that she took into account and gave weight to the opinions of both experts.

2.4.1 The close proximity integer

22 The primary judge first considered the close proximity integer. She found at [83] that the use of the words “close proximity” imports a concept of relativity into the location of the fuel metering chamber with respect to its disposition in relation to the closure. Dictionary definitions (which her Honour had quoted) of both words refer to “nearness in space or relation”. Her Honour then said:

84 The phrase “disposed in said close proximity” in claim 1 calls for an assessment of the relative nearness of the fuel metering chamber and the closure within the context of the fuel cell as a whole, and bearing in mind the express functional objectives of the invention.

85 Claim 1 defines a fuel cell for use with a combustion tool. It is a product or apparatus that comprises a combination of features as set out in the following parts of the claim. Thus, the starting point is that the fuel cell as a whole provides the context for assessing the relationship of those features to each other. As the experts agreed, fuel cells may come in different shapes and sizes.

86 The phrase “close proximity” is used to describe the disposition of the fuel metering chamber relative to the closure in the context of the fuel metering valve in which the fuel metering chamber is located. Claim 1 defines a “fuel metering valve” which is associated with the said main valve stem, and which includes “a fuel metering chamber disposed in close proximity to said closure”. The claim identifies the two components which are said to be disposed in “close proximity”, being: (1) the fuel metering chamber; and (2) the closure of the fuel cell housing (as earlier defined in the claim). These two components (and the fuel cell and housing) are defined before any reference to a valve body.

87 The “said closure” is located at the open end of the housing, through which the main valve stem protrudes. From a functional perspective the fuel metering chamber needs to be sufficiently close to the closure to allow the same measured dose of fuel to be efficiently and safely metered by the valve and dispensed through the outlet in the stem for each combustion event. In other words, it needs to be sufficiently close to the closure to allow the fuel cell, including the fuel metering valve, to function effectively and meet the objectives of the Patent. This is consistent with the functional language that follows the integer “and configured so that when the stem is in said open position only a measured amount of fuel is dispensed through said outlet.” This is also consistent with the evidence of both experts.

88 Mr MacDonald accepted that the role of the requirement of the “close proximity” feature was to ensure that the fuel metering chamber was sufficiently proximate to the closure to allow the fuel metering valve and fuel cell to function effectively.

89 In order for the fuel metering chamber to function effectively, it needs to be configured to receive delivery of a designated amount of fuel in the closed position and to allow a measured amount of fuel to be dispensed each time the valve is actuated. The fuel metering chamber does not need to be positioned adjacent to, or as close as possible to, the closure in order for the internal valve fuel cell of the invention to be configured in a manner that operates more efficiently and effectively than the fuel cells described in the prior art incorporated by reference into the Patent. The words “in close proximity” do not require this.

90 Claim 1 does not impose any limitation on the location of the fuel metering valve or valve body within the housing of the fuel cell. This is apparent from the language of the claim and was accepted by the experts. Mr MacDonald’s understanding of the phrase in the JER was that the fuel metering chamber was positioned at the end of the fuel metering valve that is crimped to the closure. However, Mr MacDonald accepted in his oral evidence that claim 1 does not require that there is an end of the fuel metering valve that is adjacent to, or engages the closure.

91 The claim does not require that the valve body, or any part of it such as the fuel metering chamber, be adjacent to the closure, or that the valve body have a “first end” which engages the closure. Requirements of that kind are introduced in later claims. In claim 1, however, it is the requirement that the fuel metering chamber be “disposed in close proximity to said closure” that performs the function of ensuring that the fuel metering chamber is sufficiently close to the closure to allow the fuel cell to function effectively. Mr MacDonald agreed that the valve body could be located away from the closure to some degree.

23 The primary judge then examined the language of the balance of the claims in the Patent and concluded that her construction was consistent with each and also with the description in the specification as a whole, including the description of the preferred embodiment by reference to the figures. She concluded:

97 Consistent with a reading of the specification as a whole including the stated objectives over the prior art, the requirement that the fuel metering chamber be disposed in “close proximity” to the closure is to be determined by assessing the relative locations of the fuel metering chamber and the closure within the context of the fuel cell as a whole, with the two components being sufficiently nearby or close to each other in that context such that the same measured dose of fuel is dispensed for each combustion event.

24 In reaching this conclusion, her Honour rejected at [98] Airco’s construction of “close proximity”, which required the fuel metering chamber to be located “next, nearest or closely adjacent, very near” (emphasis in original) to the closure. She noted that the use of the relative term “close proximity” avoids placing arbitrary numerical limits on the relative locations of the components, so as to ensure that the claim caters for the full range of shapes and dimensions in fuel cells.

25 The primary judge rejected a contention advanced by Airco that the more recently introduced claim 17, was a broadening amendment in contravention of s 102 of the Patents Act 1990 (Cth). She found that claim 17 is dependent upon and adds a further requirement, or limitation, to claim 1 as to the location of the fuel metering chamber. Her Honour further rejected a contention advanced by Airco that the wording of claim 17 supplied a definition for “close proximity” in claim 1.

2.4.2 Second end opposite integer

26 The primary judge noted that the second construction issue related to the meaning of “opposite” in the following integer from claim 1:

wherein said fuel metering valve is located within said housing and includes a valve body having a second end opposite said fuel metering chamber located within said container, and wherein the flow of fluid out the outlet of the fuel cell is solely from said separate fuel container.

(Emphasis added by the primary judge)

27 The primary judge rejected the argument advanced by Airco that the meaning of the word “opposite” is to be assessed by determining whether the fuel metering chamber is located closer to the identified “first” end of the valve body, being a fixed location, or in other words, at the other end of the valve body to the second end.

28 The primary judge adopted a dictionary meaning, as supported by the expert evidence, to conclude that the word “opposite” is to be assessed by determining whether the second end of the valve body is “opposite” the fuel metering chamber in the sense of “facing” or “across from it”, which involves a spatial relationship between the two identified objects. This, her Honour found, was consistent with the usage in the specification. The primary judge found:

154 The word “opposite” in the context of claim 1 is used in relation to two separate and different components: the second end of the valve body and the fuel metering chamber, not two ends of the one component. This usage is in contrast to other uses in the specification where two ends of the same component, such as the valve stem are being discussed.

155 The word “opposite” as used in the claim integer is a preposition. It defines a spatial relationship between these two separate components, being a second end of a valve body and a fuel metering chamber. In that context, it requires that a second end of a valve body be “facing” or “across from” a fuel metering chamber, with the two components being across from each other on the same axis (or, having a co-axial relationship with each other).

156 The fuel metering chamber and second end of the valve body identified in claim 1 are two separate components. The use of “opposite” in this context is not the same as the use to describe two ends of the same component. It is wrong to suggest that a word used more than once in the Patent must be construed consistently regardless of the context in which that word is used. Where the context of use indicates that a different meaning is appropriate for that context, that meaning should be adopted.

157 Thus, the claim requires that the “second end” of the valve body be “opposite” the “fuel metering chamber”. It does not refer to “the opposite end” of the valve body. The claim does not define the relationship of the fuel metering chamber with reference to any other component, including any other “end” of the valve body. The only end of the valve body identified in claim 1 is the “second end” of this feature.

29 Having regard to the purpose or function of the integer, the primary judge said:

163 The requirement in the claim that the second end of the valve body be “opposite” the fuel metering chamber imposes the functional requirement that those two components be facing or across from each other, so that fuel will flow directly from the second end, (in the separate fuel container), to the fuel metering chamber. From there, upon actuation, it will follow the pathway that has already been defined earlier in the claim via the main valve stem, through the outlet and into the combustion tool. This is the context in which the word “opposite” is used in the claim.

30 This, the primary judge said, was different to other references in the specification to “opposite end” where, in each case, there is one component being discussed, and it is the other end of that component to which “opposite” is directed. In rejecting the Airco submission, the primary judge found that “[i]n the integer, the ‘end’ is the second end of the valve body, and ‘opposite’ is used in relation to another component, not the other end of the valve body”. In this context the primary judge concluded at [172] that:

… by requiring the fuel metering chamber to be “opposite” a second end in the way contended by [Illinois], the source of the fuel into the valve (the second end of the valve body) and the component responsible for storing and metering that fuel out of the valve body (the fuel metering chamber), form the components integral to the passage of fuel through the valve and the valve’s metering functionality, are, consistently with the description, aligned along the one axis.

31 The primary judge referred to the following illustration of the Airco Fuel Cell which had been prepared by Mr MacDonald:

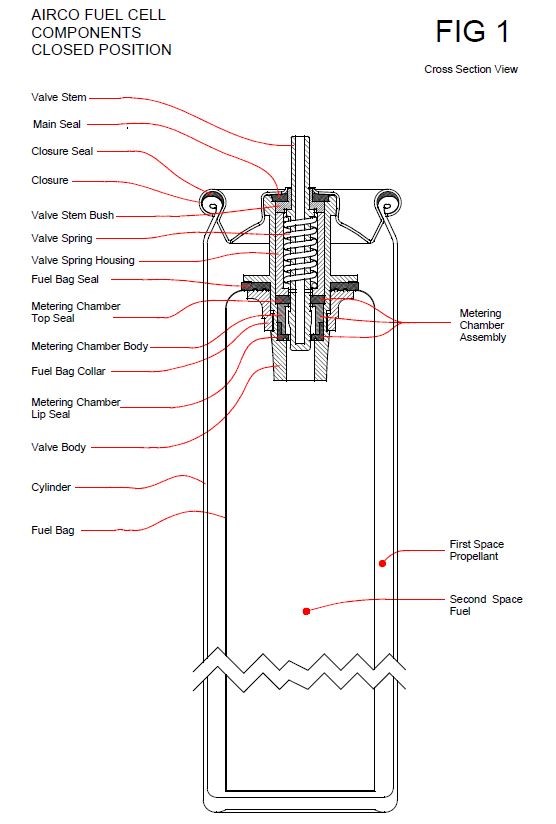

32 The primary judge noted at [175] that in the Airco Fuel Cell, the fuel metering chamber is positioned at the end of the fuel metering valve furthest from the closure. The biasing element, or spring, is interposed between the fuel metering chamber and the closure, being the first end of the valve body.

33 Consistent with the primary judge’s finding as to the meaning of the close proximity integer, her Honour noted at [181] that the requirement that the fuel metering chamber be disposed in “close proximity” to the closure is to be determined by assessing the relative locations of the fuel metering chamber and the closure within the context of the fuel cell as a whole, with the two components being sufficiently nearby or close to each other in that context that the same measured dose of fuel is dispensed for each combustion event. Dr Wallace gave evidence that the length of the Airco Fuel Cell housing from the top of the closure to the bottom end of the housing is 158mm, the distance between the fuel metering chamber and the top-most part of the closure where the valve stem protrudes is 17.5mm, the length of the fuel metering chamber from the top of the chamber seal to the bottom of the bottom chamber seal is 7.1mm and the fuel metering chamber is located 133.4mm from the bottom end of the housing. The primary judge found these measurements provide an idea of the relativities involved (rather than provide a mathematically precise answer to infringement) and assisted her in reaching the conclusion at [185] that, relative to the length of the Airco Fuel Cell housing, the fuel metering chamber is located in close proximity to the closure of that canister and, in fact, much closer to the fuel cell closure compared to the other end of the housing. In functional terms, the primary judge found that the fuel metering chamber is sufficiently near to the closure to allow it to achieve the objectives of the Patent, including that leakage is kept to a minimum.

34 In relation to the second end opposite integer, the primary judge reasoned as follows:

197 Airco submits that the fuel metering chamber in the Airco Fuel Cell is located at and within what the Patent teaches to be the second end, and for that reason it cannot be said to have a “second end opposite said fuel metering chamber located within said chamber”. Airco’s construction requires the fuel metering chamber to be located at or closer to the first end of the valve body than the second end.

198 I do not accept that the second end of the valve body is the flat edge at the end of the valve body which is in the fuel container. This narrow view of the second end of the valve body would be inconsistent with the depiction in Figure 1 which indicates a region or area at the end of the valve body, rather than flat edge at the extremity of the valve body. The description at [26] has the second end “defining a nipple portion of the valve body”. This is repeated at [27] which describes the second end “having the nipple portion”. These descriptions suggest a three dimensional second end, rather than a planar edge of the end. Whilst these are descriptions of the preferred embodiment, they are inconsistent with the second end being just a flat edge. I consider that the second end of the valve body is the region at the end of the valve body where fuel enters the valve (the nipple portion) which extends from the flat edge of the extremity of the valve body.

199 That being said, adopting the construction of “opposite” that is facing, or across from, I consider that the Airco Fuel Cell has this integer.

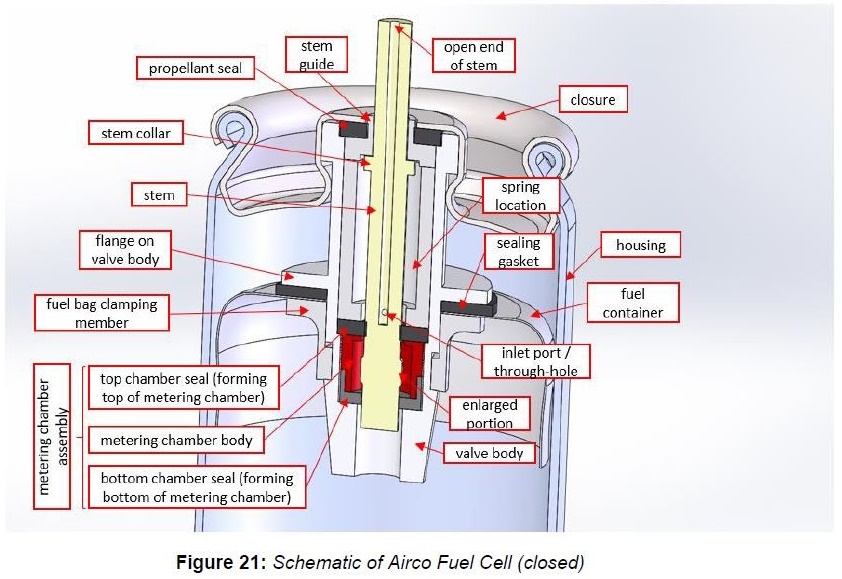

200 I consider that the region at the second end of the valve body (where the arrow is pointing for “valve body” on Dr Wallace’s figure 21 diagram of the Airco Fuel Cell) is the second end, rather than the extreme planar edge at the end of the valve in the fuel bag. Dr Wallace’s figure 21 is extracted below:

201 This region at the end of the valve body which is in the fuel container is on the same axis as the fuel metering chamber, and facing or across from that chamber. Fuel flows from the fuel chamber along the axis until it exits the stem, in contrast to the fuel flow of the prior art.

35 The primary judge concluded that the Airco Fuel Cell infringed the relevant claims.

3. AIRCO’S SUBMISSIONS ON APPEAL

36 It is convenient to address Airco’s submissions in the order in which the primary judge addressed them, rather than as presented on appeal.

37 Airco submits that the primary judge erred in construing the close proximity integer as requiring an assessment of the relative nearness of the fuel metering chamber and the closure within the context of the fuel cell as a whole. In this regard, it submits that the size of the fuel cell “as a whole” is not disclosed anywhere in the Patent and is an undisclosed metric of indeterminate length, with no apparent relevance to making the invention work. Airco submits that the construction adopted by the primary judge failed to give effect to the natural meaning of “close proximity” as emphasising the requirement of closeness, rather than simply proximity. In this context, Airco contends that the construction adopted by the primary judge was contrary to the expert evidence.

38 Airco submits that the primary judge ought to have construed the close proximity integer as requiring an assessment of the relative nearness of the fuel metering chamber and the closure “within the context of the location of the fuel metering chamber in the fuel metering valve”. It contends that this construction is supported firstly, and most significantly, by the language of claim 1, which requires that there be a “fuel metering valve…including a fuel metering chamber” and that the fuel metering chamber be located: (i) “opposite” the second end of the valve body (which is located within the fuel container); and (ii) in “close proximity” to the closure. That is, it will not be sufficient to satisfy claim 1, that a fuel metering chamber is merely located inside the fuel metering valve and “opposite” the second end unless it is also located “in close proximity” to the closure. The assessment of “close proximity” must be undertaken in circumstances where it is “already a given” that the fuel metering chamber is contained within the valve body. Secondly Airco’s construction is said to be confirmed in the Patent specification at [22], which explicitly contemplates that the fuel metering chamber might be located within the valve body but not in “close proximity” to the closure. Claim 1 elevates the preferable feature of “close proximity” to a requirement. Thirdly, Airco’s construction is consistent with the preferred embodiments in figures 1 and 2 of the Patent where fuel metering chamber (38) is depicted as located at the upper end of valve body (34) (“opposite” the second end) immediately under and adjacent to the closure (16). The only component which separates the fuel metering chamber, depicted in figures 1 and 2, from the closure is the main/outlet seal (42).

39 Airco submits that applying the correct construction of this integer, the Airco Fuel Cell does not infringe claim 1 because, as Dr Wallace agreed in cross-examination “the fuel metering chamber could not be much further away from the closure”. In circumstances where it is already a given, having regard to the structure of claim 1, that the fuel metering chamber is contained within the valve body, a fuel metering chamber located in that part of the body furthest from the closure cannot be characterised as being in “close proximity” to the closure. Moreover, the primary judge erred in finding at [186] that the location of the fuel metering chamber achieves the objectives of the Patent, at least to the same extent as the invention disclosed and claimed, because the Airco Fuel Cell required the use of an additional seal and components when compared with the preferred embodiment.

40 In relation to the second end opposite integer, Airco submits that the primary judge ought to have construed this integer as requiring the fuel metering chamber to be located:

(a) at the other (ie “opposite”) end of the valve body to the “second end” of the valve body; and

(b) outside (not “within”) the fuel container.

41 Airco supplies the following reasons why it submits that the primary judge erred at [155] in construing “opposite” to mean “facing” or “across from” with two components “having a co-axial relationship with each other”.

42 First, it submits that the term “opposite” is used consistently throughout the Patent to identify two ends of various objects; see [20], [25], [27] and [33] of the Patent. It notes that Illinois’ expert Dr Wallace accepted in cross-examination that “opposite” is used in [20] to mean “a position at the other end” and that it would not be accurate to describe the two ends as “facing” each other, rather each end was “facing away from the other end”, an observation apposite also in relation to the usage of “opposite” with regards to the biasing element identified in [25] and the actuator arm in [33] of the Patent. Airco submits that it is the description in the Patent at [27] that discloses the second end opposite integer in the preferred embodiment. Dr Wallace gave evidence that this passage discloses: (i) that the fuel metering chamber is to be located at the first end of the valve body; (ii) that opposite is used to identify “a location at the first end”; and (iii) that it is not a natural use of language to describe those locations as facing each other. It submits that there is no reason why the term “opposite” in the claim should have a different meaning to the way that it is used in the specification, and in particular the way that it is used in [27].

43 Secondly, the construction adopted by the primary judge is said to be counterintuitive in that it requires the skilled addressee, after reading four passages where “opposite” is used to describe the two ends of an elongate object, to understand “opposite” to mean “facing” in a “co-axial” fashion, which does not appear anywhere in the Patent. There was no basis, Airco submits, for the primary judge to distinguish at [154] the use of “opposite” in claim 1 from the manner in which it was used elsewhere in the specification.

44 Thirdly, Airco argued, the construction preferred by the primary judge renders the term redundant because, as Mr MacDonald said “every component of the fuel valve would then be opposite the second end”. As Dr Wallace conceded, that construction meant that every item along the axis between the second end and the closure is opposite the second end, which, he said, “might not really be appropriate”.

45 Fourthly, the primary judge wrongly found at [163] that the word “opposite” imposed “the functional requirement” that “fuel will flow directly from the second end ... to the fuel metering chamber”.

46 Fifthly, focussing on the preferred embodiments of figures 1 and 2 of the Patent, it cannot be said that the fuel metering chamber is “facing” the second end. There is a large number of components (including the seal or gasket 72, the biasing element 36, the main valve stem 26 and the radially inwardly projecting lip 46) located between the second end 62 and fuel metering chamber 38.

47 Finally, Airco submits that the Airco Fuel Cell does not have “a valve body having a second end opposite said fuel metering chamber located within said chamber” because:

(a) the fuel metering chamber is not located “opposite” the second end of the valve body; instead it is located within, immediately adjacent to, touching or encircled by the second end of the valve body; and

(b) the fuel metering chamber itself is located within the fuel container, which also contains the second end of the valve body which the fuel metering chamber is required to be “opposite”.

48 There was no real dispute as to the principles of claim construction applicable, or that the primary judge correctly set out those principles. They are conveniently summarised in Jupiters Ltd v Neurizon Pty Ltd [2005] FCAFC 90; 65 IPR 86 at [67] (Hill, Finn and Gyles JJ) as follows:

(i) the proper construction of a specification is a matter of law: Décor Corp Pty Ltd v Dart Industries Inc (1988) 13 IPR 385 at 400;

(ii) a patent specification should be given a purposive, not a purely literal, construction: Flexible Steel Lacing Company v Beltreco Ltd (2000) 49 IPR 331 at [81]; and it is not to be read in the abstract but is to be construed in the light of the common general knowledge and the art before the priority date: Kimberley-Clark Australia Pty Ltd v Arico Trading International Pty Ltd (2001) 207 CLR 1 at [24];

(iii) the words used in a specification are to be given the meaning which the normal person skilled in the art would attach to them, having regard to his or her own general knowledge and to what is disclosed in the body of the specification: Décor Corp Pty Ltd at 391;

(iv) while the claims are to be construed in the context of the specification as a whole, it is not legitimate to narrow or expand the boundaries of monopoly as fixed by the words of a claim by adding to those words glosses drawn from other parts of the specification, although terms in the claim which are unclear may be defined by reference to the body of the specification: Kimberley-Clark v Arico at [15]; Welch Perrin & Co Pty Ltd v Worrel (1961) 106 CLR 588 at 610; Interlego AG v Toltoys Pty Ltd (1973) 130 CLR 461 at 478; the body of a specification cannot be used to change a clear claim for one subject matter into a claim for another and different subject matter: Electric & Musical Industries Ltd v Lissen Ltd [1938] 56 RPC 23 at 39;

(v) experts can give evidence on the meaning which those skilled in the art would give to technical or scientific terms and phrases and on unusual or special meanings to be given by skilled addressees to words which might otherwise bear their ordinary meaning: Sartas No 1 Pty Ltd v Koukourou & Partners Pty Ltd (1994) 30 IPR 479 at 485-486; the Court is to place itself in the position of some person acquainted with the surrounding circumstances as to the state of the art and manufacture at the time (Kimberley-Clark v Arico at [24]); and

(vi) it is for the Court, not for any witness however expert, to construe the specification; Sartas No 1 Pty Ltd, at 485–486.

4.2 The close proximity integer

49 The close proximity integer appears at (4) of claim 1 and is as follows:

a fuel metering valve associated with said main valve stem, including a fuel metering chamber disposed in close proximity to said closure and configured so that when said stem is in said open position only a measured amount of fuel is dispensed through said outlet

50 The requirement that the fuel metering valve include a fuel metering chamber “disposed in close proximity to said closure” draws attention to two parts. The fuel metering chamber within the fuel metering valve on the one hand and the “closure” on the other. The latter part is identified in the context of the claim at integer (2) where the fuel cell is required to include a housing “defining an open end enclosed by a closure”. The “closure” is not a part of the fuel metering valve, but form parts of the housing, which includes within it a separate fuel container, as identified in integer (5), and the fuel metering valve which is identified in integer (6).

51 Integer (4) defines the relative position of the fuel metering chamber to the closure. The fuel metering chamber is to be included within the fuel metering valve but nevertheless be “in close proximity to said closure”.

52 Although Airco submits that the primary judge ought to have considered the question of proximity in the context of the fuel metering chamber being in the fuel metering valve, the plain words of the claim indicate otherwise. The “close proximity” is to be between the fuel metering chamber, which is a component of the fuel metering valve, and “said closure”, which is a separate part of the fuel cell defined in integer (1) to enclose an open end of the fuel cell. Accordingly, the relative distance between the two is not, by the language of the claim, governed by the location of the fuel metering chamber within the valve, but by reference to the proximity of the chamber to the closure, as part of the fuel cell as a whole.

53 This the primary judge recognised at [85], noting that “the starting point is that the fuel cell as a whole provides the context for assessing the relationship of those features to each other”. We respectfully agree that the phrase “close proximity” is used to describe the disposition of the fuel metering chamber relative to the closure in the context of the fuel cell as a whole.

54 Airco criticises the construction adopted by the primary judge on the basis that the size or length of the fuel cell is not disclosed in the Patent. However, none of the other components of the claim are defined by reference to a size or dimension. The components may vary in dimension and still fall within the claim. The scope of such a term is to be understood by reference to the role that the particular part is to play in the product described in the claim. As Aickin J said in a familiar passage in Minnesota Mining & Manufacturing Company v Beiersdorf (Australia) Ltd [1980] HCA 9; 144 CLR 253 at 274 (Barwick CJ, Stephen, Mason and Wilson JJ agreeing), lack of precise definition in claims is not fatal to validity so long as they provide a workable standard suitable to the intended use.

55 In this context in our respectful view the primary judge was correct to take note of the evidence of Mr MacDonald, who accepted that the requirement of “close proximity” is to ensure that the fuel metering chamber is sufficiently proximate to allow the fuel metering valve and fuel cell to function effectively. As explained by her Honour at [89], in order for the fuel metering chamber to function effectively, it needs to be configured to receive delivery of a designated amount of fuel in the closed position and to allow a measured amount of fuel to be dispensed each time the valve is actuated. The fuel metering chamber does not need to be positioned adjacent to, or as close as possible to, the closure in order for the internal valve fuel cell of the invention to be configured in a manner that operates more efficiently and effectively than the fuel cells described in the prior art incorporated by reference into the Patent. The words “in close proximity” do not require this. This was an appropriate functional consideration to take into account in construing the specification in the context of the construction of the claim.

56 Furthermore, dependent claim 3 provides a measure of support for the view adopted by the primary judge. Claim 3 introduces a “first end” of the valve body and provides “wherein a first end of said valve body engages said closure” (emphasis added). The explicit provision of a spacial relationship between the valve body and the closure in claim 3 serves to emphasise that broader claim 1 does not itself provide any limitation as to where the fuel metering valve must be located within the housing. A fuel metering valve located anywhere along the length of the fuel cell will fall within claim 1, provided that the fuel metering chamber is located in “close proximity” to the closure. As the primary judge observed at [93], this supports a construction that the relative location of the fuel metering chamber and closure in claim 1 is to be determined by reference to the fuel cell as a whole.

57 Claim 7, provides what may be considered to be weaker support for the view that the relative location of fuel metering chamber and closure is to be judged by reference to the fuel cell as a whole, insofar as that claim refers to points of specific engagement between parts, thereby emphasising the fact that claim 1 is not so confined.

58 In our view, Airco’s contention that its approach is “consistent with” the preferred embodiments in figs 1 and 2 and so should be adopted reflects an example of the prohibited use of embodiments to place a gloss on the language of the claim: Kimberley-Clark Australia Pty Ltd v Arico Trading International Pty Ltd [2001] HCA 8; 207 CLR 1 at [15] (Gleeson CJ, McHugh, Gummow, Hayne and Callinan JJ); Welch Perrin & Co Pty Ltd v Worrel [1961] HCA 91; 106 CLR 588 at 610 (Dixon CJ, Kitto and Windeyer JJ); Interlego AG v Toltoys Pty Ltd [1973] HCA 1; 130 CLR 461 at 478 (Barwick CJ and Mason J). Whilst it may be the case that in fig 1 the fuel metering chamber (38) as situated within the fuel metering valve (34) is “next to” or “very near to” the closure, that juxtaposition cannot of itself drive the construction of the claim. That embodiment is expressly identified as a preferred embodiment. It was not a definition of the claim.

59 Finally, we do not accept the criticism advanced by Airco that the primary judge erred insofar as her construction was contrary to the evidence of both experts. As the principles summarised in Jupiters make plain, it is for the Court to determine the meaning of the language of the claims, aided by the evidence of experts to assist in understanding unfamiliar terms and the technical context of the subject matter. Expert opinion does not supplant the judicial role. It is apparent from the reasons that the primary judge considered and gave weight to the evidence of the experts where she considered it to be appropriate: see, for example, [88], [90] and [91]. However, her Honour was not obliged to adopt a particular construction of the claim based on the evidence of one or other of the expert witnesses.

4.3 The second end opposite integer

60 Integer (6) of claim 1 is:

(6) wherein said fuel metering valve is located within said housing and includes a valve body having a second end opposite said fuel metering chamber located within said container

61 The primary judge found “opposite” to define a spacial relationship between a second end valve body and a fuel metering chamber requiring that the second end be “facing” or “across from” a fuel metering chamber, with the two components being across from each other on the same axis.

62 On appeal, Airco contends that the second end opposite integer imposes two requirements, the first being that the fuel metering chamber be located at the other end of the valve body to the “second end”, and the second being that the fuel metering chamber be outside the fuel container. The first requirement involves an assessment as to whether the fuel metering chamber is located closer to a “first” end of the valve body than the second end.

63 We consider that the primary judge was correct to reject the construction advanced by Airco.

64 The word “opposite” is not used in claim 1 to refer to two ends of the same component (the valve body) but rather to two different components, being the second end of the valve body on the one hand and the fuel metering chamber on the other. The primary judge noted this at [154] and [156]. In this respect the language of the claim, and its matching consistory clauses in the Brief Summary of the Invention, is broader than the language used in the passages of the specification identified by Airco in its submissions. In each of those instances, the word “opposite” is used to identify one end of a specified component relative to the other end of the same component. Thus in [20] of the Patent (set out at [11] above) a main valve stem (26) is configured for emitting fuel from the container (22) “and as such has an outlet 28 at a first end 30 projecting from the housing, and a second end 31 opposite the first end”. In [25] the word “opposite” is first used in relation to the main valve stem 26 and secondly in relation to the biasing element 36. In both uses the description identifies the other end of the one component. The same is true, in relation to different components, of the usage in [27] and [33]. This distinction was noted by the primary judge at [145] to [148] before her Honour observed at [149]:

When used in the specification in relation to two ends of one component, “opposite” is used to indicate the other end of that component by reference to “opposite end”. That is not the context in which it is used in claim 1.

65 Contrary to Airco’s submission, the construction adopted by the primary judge does not involve construing the same word to have different meanings in the same document. The word “opposite” is sensitive to context. In claim 1, it is the fuel metering chamber that is to be opposite a second end of the valve body, not a “first end” of the valve body, which is not identified in claim 1 at all. The construction propounded by Airco involves reading a requirement into the integer that is not present.

66 Nor do we accept Airco’s argument that the primary judge’s construction renders the word “opposite” redundant. As the primary judge observes at [158], by this integer, the claim imposes the requirement that there is a relationship between the second end, which is the end of the valve body in the separate fuel container where the fuel is going to come from, and the fuel metering chamber, which is where the fuel must flow in order for the invention to work. Fuel flows from the container into the second end of the valve body, the cavity and the metering chamber prior to being emitted from the outlet of the valve stem. The words “second end opposite said fuel metering chamber” serve to align the second end with the fuel’s measured storage and dispensation component (the fuel metering chamber), thereby aligning the two co-axially, as the primary judge found at [161]. No other language in the claim performs this function, which serves also to distinguish the arrangement of the invention from that of the prior art, which placed the fuel metering chamber orthogonally to the second end of the valve body.

67 Airco did not advance any reason why, on her Honour’s construction, a finding of infringement should not be made. Accordingly, it is sufficient to dispose of the appeal adversely to Airco to find, as we do, that Airco has not demonstrated that the primary judge erred in her construction of either the close proximity integer or the second end opposite integer.

68 For completeness, however, we note that her Honour concluded that integer (4) was met because relative to the length of the Airco Fuel Cell as a whole, the fuel metering chamber is located in close proximity to the closure of the canister and much closer to the fuel cell closure compared to the other end of the housing. This may be seen from the diagram at [31] above. Her Honour concluded that integer (6) was met because the second end of the valve body, as depicted in the figure set out at [34] above is opposite, in the sense of facing on the same axis, the fuel metering chamber as shown.

69 For the reasons set out above, the appeal must be dismissed. Airco must pay Illinois’ costs of the appeal.

I certify that the preceding sixty-nine (69) numbered paragraphs are a true copy of the Reasons for Judgment of the Honourable Justices Rares, Moshinsky and Burley. |

Associate:

Dated: 13 February 2023